Bi-Directional Cross Conveyors equipped with wing-type tail drums for efficient material handling.

Electrical Control Panel with an additional 11 switches to accommodate stackers and auxiliary equipment.

High-Capacity Screw Washer (MFW 3625 S) with a rising current setup for superior washing efficiency.

Run-On Jacks for quick and effortless setup, saving valuable time.

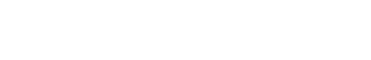

Triple Shaft Horizontal Screen for precise material separation and durability.

Washing Nozzles strategically placed at each deck for thorough cleaning.

3-Axle Semi-Trailer Design for easy transportation and highway compliance.