Il existe deux types de concasseurs à mâchoires : à simple ou à double genouillère, selon le système de mouvement de la mâchoire. Les concasseurs à mâchoires à simple genouillère sont les plus courants.

Applications

Applications de concassage primaire et secondaire pour les carrières, les mines, le recyclage et les minéraux industriels.

Matériaux d'alimentation les plus durs, applications de concassage stationnaires, souterraines et mobiles.

- 'Capacité élevée

- Réduction élevée

- Faible usure de la plaque de mâchoire

- Grande capacité d'acceptation de l'alimentation

MJ 60 |

MJ 65 |

MJ 70 |

MJ 90 |

MJ 110 |

MJ 130 |

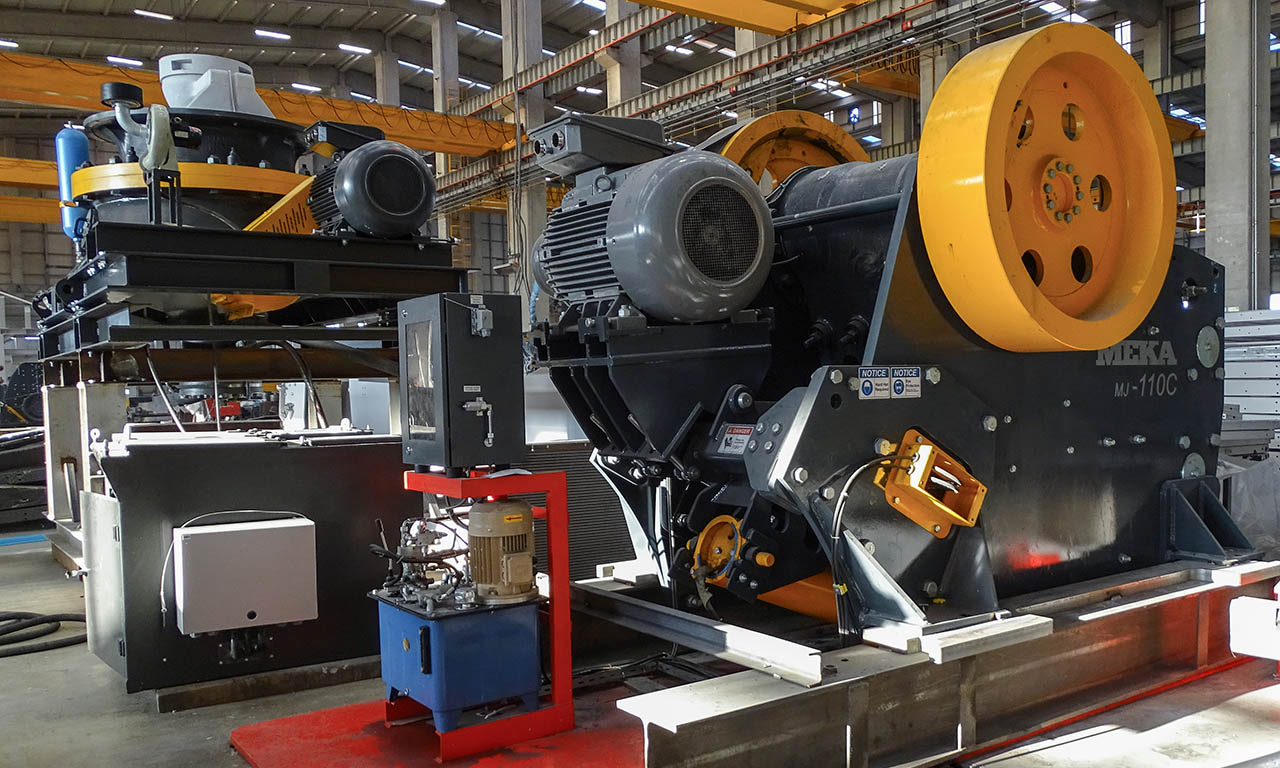

MJ 110C |

MJ 120C |

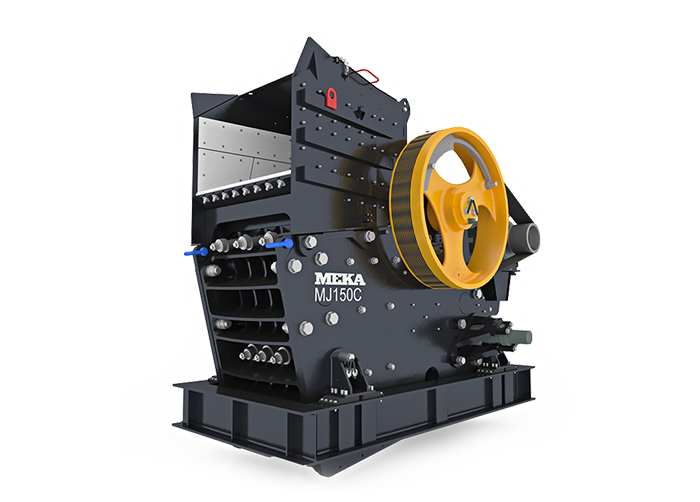

MJ 150C |

MJS 90 |

MJS 110 |

|

| Ouverture d’Alimentation (mm) | 610x380 | 650x500 | 700x400 | 900x650 | 1100x850 | 1300x1000 | 1070x770 | 1200x870 | 1400x1200 | 900x200 | 1100x350 |

| CSS (Réglage Min - Max) (mm) | 40-150 | 40-150 | 30-100 | 60-150 | 100-200 | 125-250 | 75-210 | 70-175 | 125-250 | 25-75 | 25-100 |

| *Capacité (mtph) | 20-80 | 25-100 | 25-100 | 50-200 | 100-300 | 275-600 | 135-340 | 175-595 | 340-970 | 10-80 | 40-200 |

| Puissance (kW) | 30 | 45 | 45 | 75 | 132 | 160 | 110 | 160 | 200 | 30 | 75 |

| **Poids (kg) | 6000 | 7000 | 4200 | 11400 | 33000 | 43000 | 19000 | 27990 | 55400 | 6000 | 11000 |

*Pour un matériau pesant 1,6 t/m³ ou 100 lbs/ft³. Les valeurs de capacité sont données à titre indicatif, les performances du concasseur peuvent varier en fonction de la granulométrie de l'alimentation, de la teneur en eau de l'alimentation, de l'aptitude au broyage du matériau, de la vitesse de rotation du concasseur, de la puissance installée et de la conception du circuit de broyage.

**Les poids indiqués ne comprennent pas le moteur d'entraînement, les pieds de support, la plate-forme de maintenance, les goulottes d'entrée et de sortie.

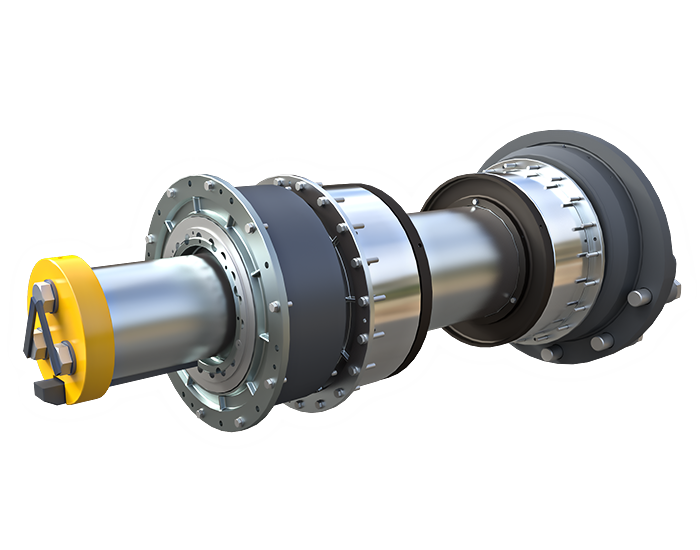

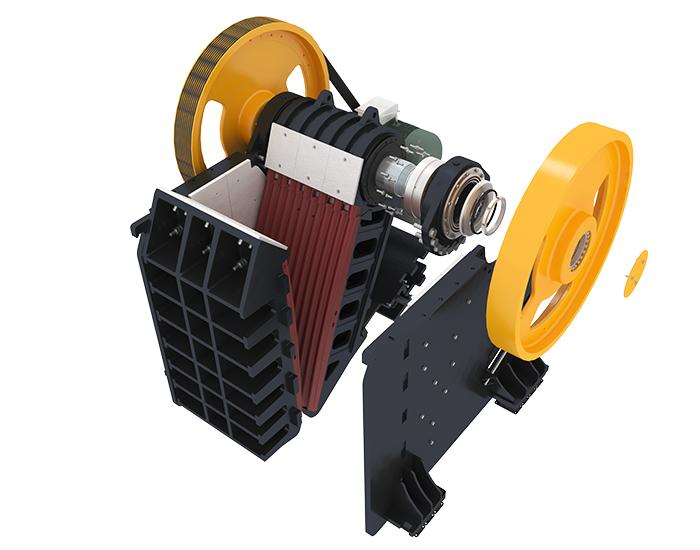

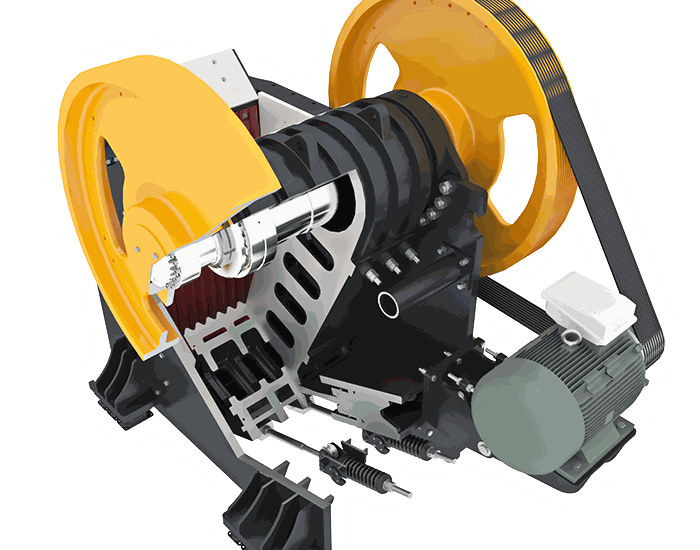

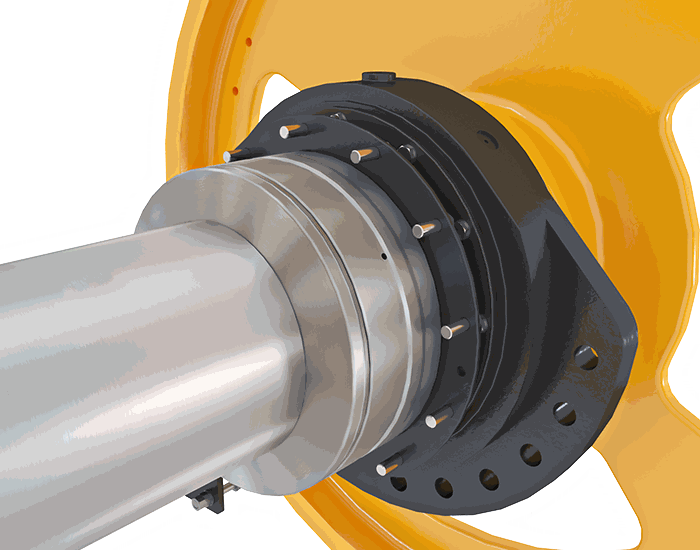

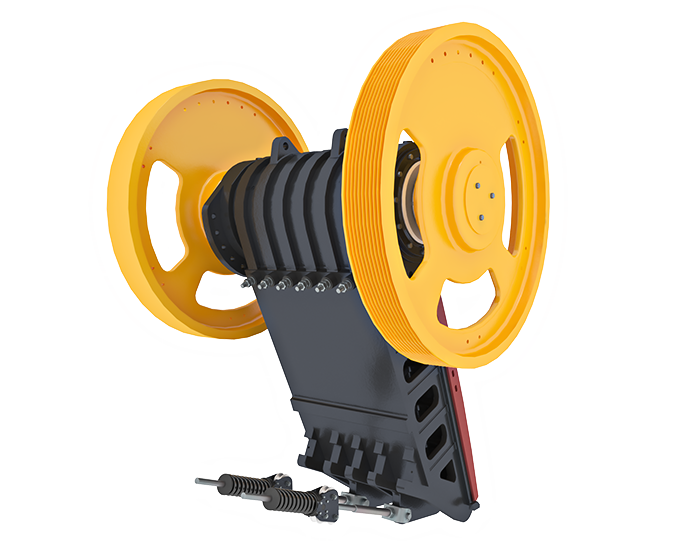

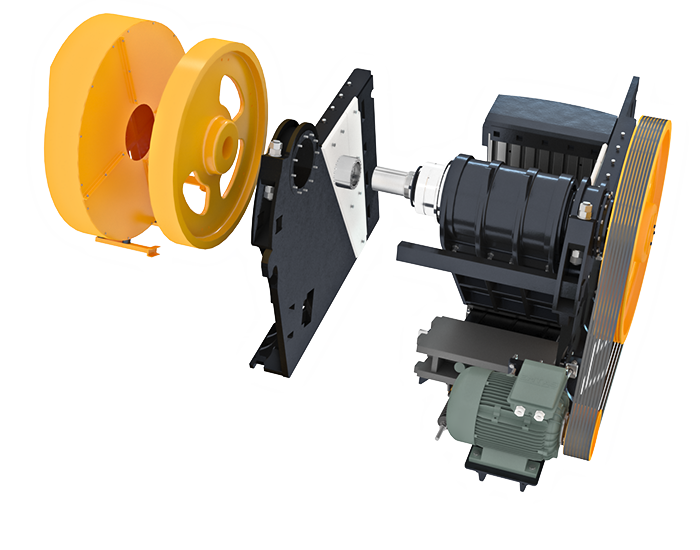

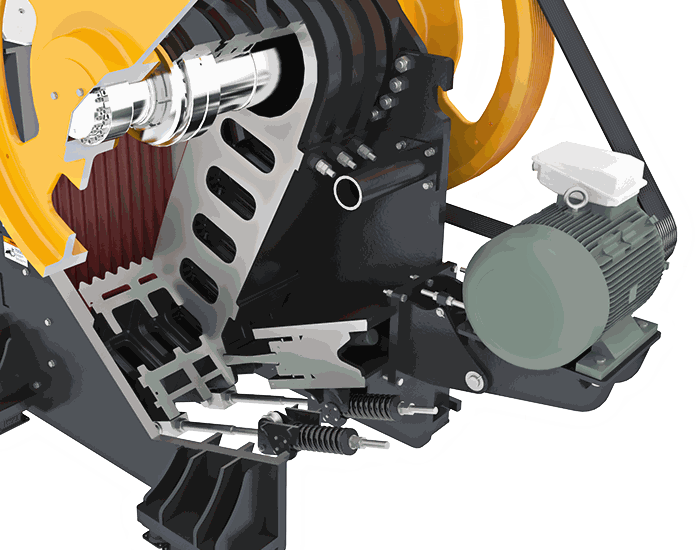

Les concasseurs à mâchoires comprennent une mâchoire fixe et une mâchoire mobile. Le matériau est broyé entre la mâchoire mobile et la mâchoire fixe par l'application d'une force de compression produite par le mouvement elliptique de la mâchoire mobile. La mâchoire mobile, qui est soutenue par le haut par un arbre excentrique, est reliée à la barre de tension et intègre une plaque à genouillère inclinée qui absorbe les charges cycliques dans la section inférieure.

Il existe deux types de concasseurs à mâchoires : à simple ou à double genouillère, selon le système de mouvement de la mâchoire. Les concasseurs à mâchoires à simple genouillère sont les plus courants.

- L'utilisation de concasseurs à mâchoires dans les applications souterraines est pratique et courante, car ils peuvent être fabriqués avec peu de pièces et sont faciles à transporter, à assembler et à entretenir.

- Il n'y a pas de problème de capacité, car la capacité souhaitée peut être atteinte en utilisant plus d'un concasseurs côte à côte si nécessaire.

- Ils sont faciles à entretenir et abordables.

- Le remplacement des mâchoires usées ne prend pas beaucoup de temps.

Les concasseurs à mâchoires peuvent être utilisés comme concasseurs de première étape dans les installations de petite et moyenne taille, ainsi que pour le concassage secondaire si nécessaire.

La distance d'oscillation de la mâchoire varie généralement entre 20 et 40 mm. Ainsi, le réglage du côté fermé de la déchargement sont aussi importantes que celles de l'entrée du concasseurs à mâchoires. Les concasseurs peuvent être réglés dans certaines limites.