Les cribles de déshydratation sont des équipements qui jouent un rôle important dans les applications de traitement par voie humide et sont conçus pour produire un produit homogène, sans gouttes, qui peut être transporté pour être stocké.

Applications

Les cribles de déshydratation peuvent être appliqués dans le traitement d'une large gamme de matériaux, y compris notamment :

- Sable

- Granulats (pour production de béton)

- Déchets de construction et de démolition

- Minerai de fer

- Charbon

- Autres minerais

Pourquoi MEKA Cribles De Déshydratation?

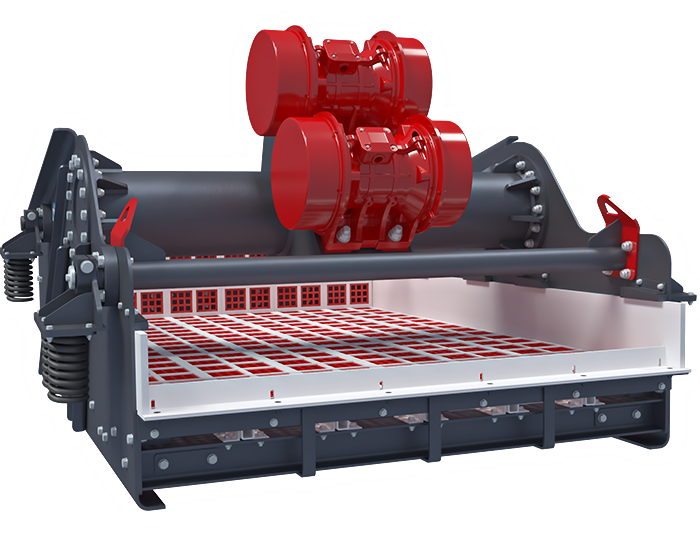

- Déshydratation maximale des matérieux sableux

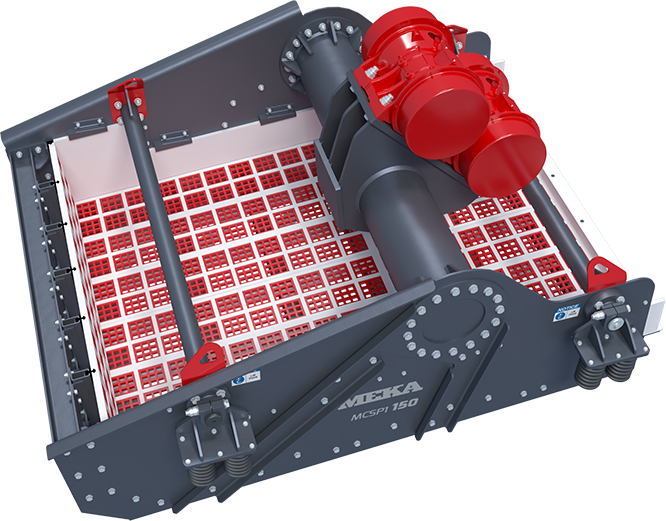

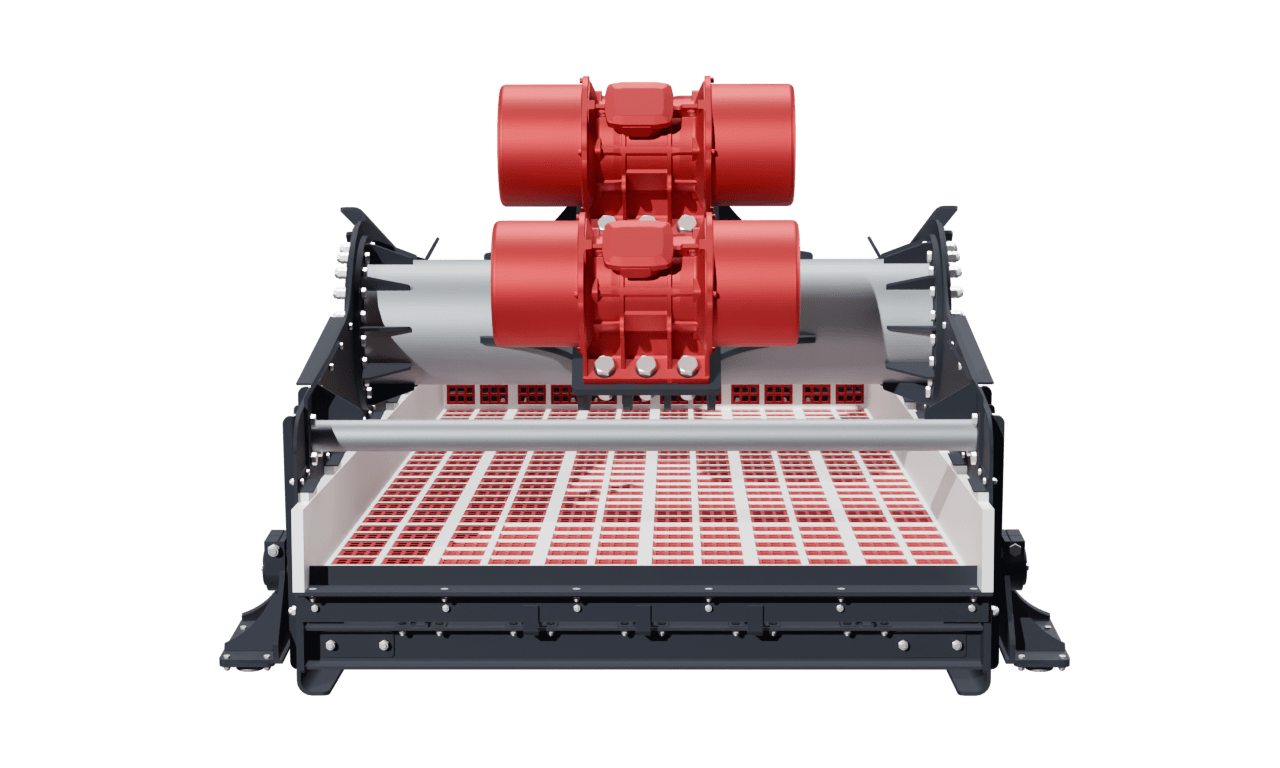

- Les vibromoteurs à haute fréquence assurent un rapport puissance/surface élevé soutenant la purification la plus efficace de votre produit sableux

- Résistance maximale à l'usure

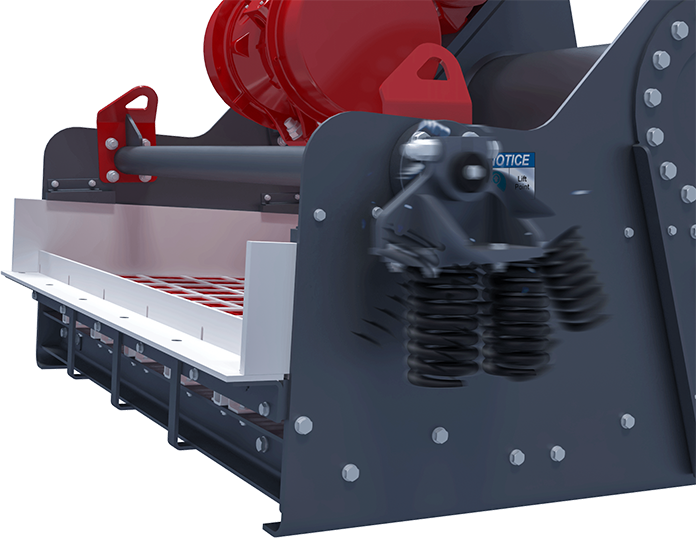

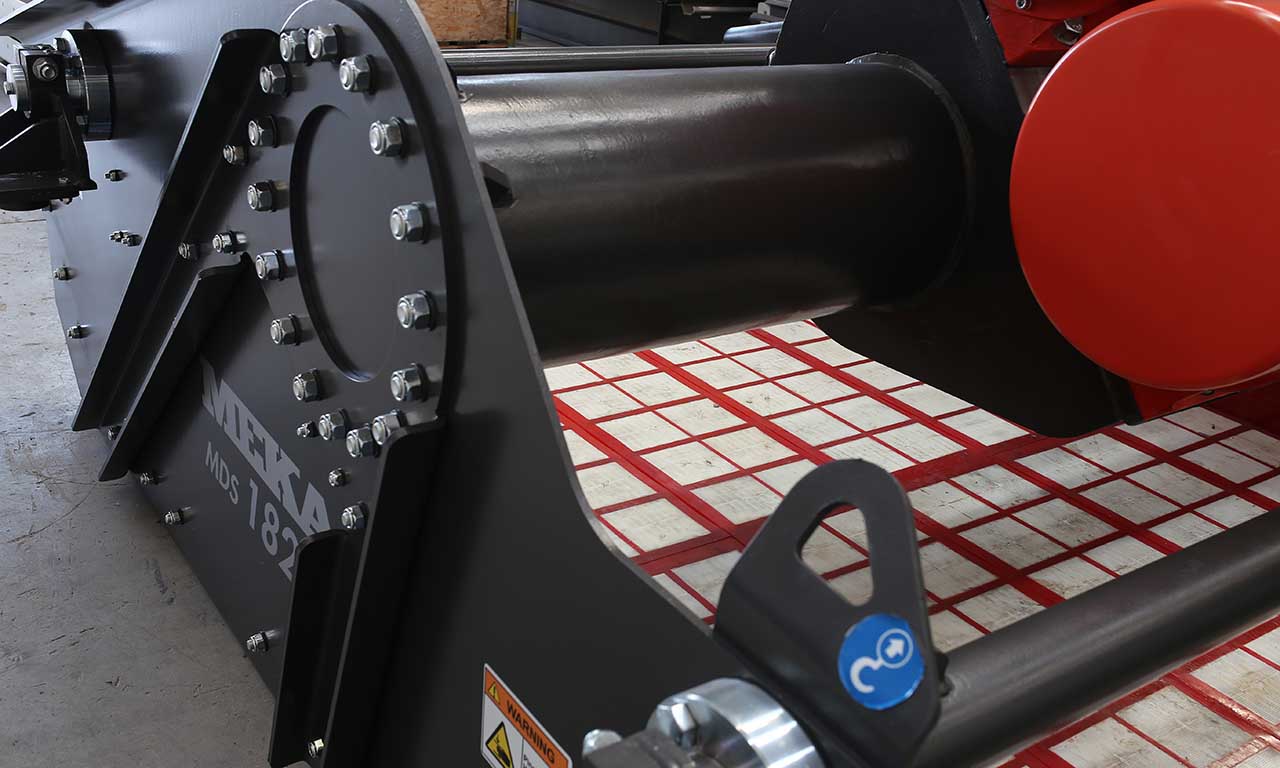

- La protection changeable de la revêtement latérale en polyuréthane sur les cribles MDS minimise le contact du matériau avec l'acier, ce qui réduit l'abrasion et augmente la durée de vie de la machine. Par ailleurs, il existe des goulottes de décharge entièrement revêtues de caoutchouc pour une résistance maximale à l'usure.

- Classification simple et efficace

- Le profondeur de godet plus profonde permet aux cribles d'éliminer plus d'humidité et de maintenir le pourcentage le plus élevé de produit vendable

- Facilité d'entretien

- Panneaux modulaires en polyuréthane non boulonnés en standard pour faciliter l'entretien.

Cribles De Déshydratation Spécifications Techniques

MDS 1224 |

MDS 1824 |

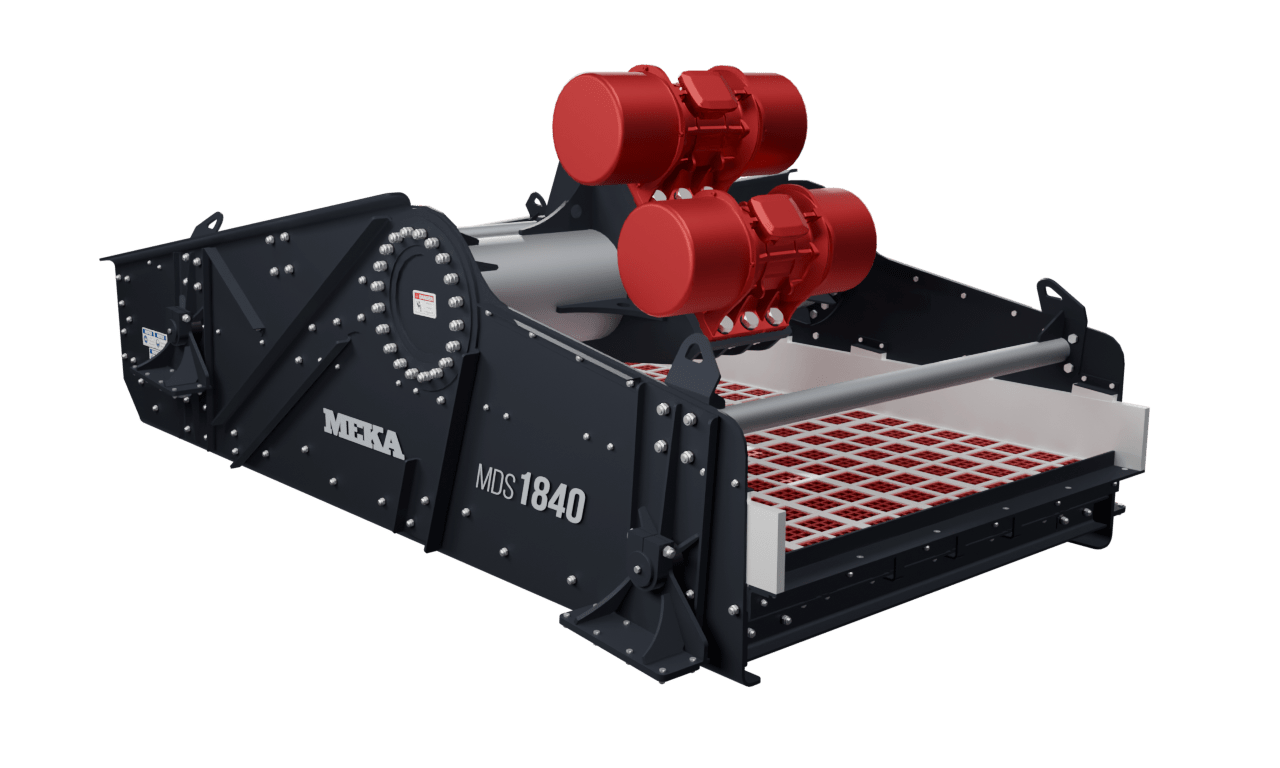

MDS 1840 |

|

| Largeur x Longueur (mm) | 1200x2400 | 1800x2400 | 1800x4000 |

| Nombre d'étages | 1 | 1 | 1 |

| Puissance @50Hz (kW) | 2x2,88 | 2x7,35 | 2x6,1 |

| Puissance @60Hz (kW) | 2x3,9 | 2x6,6 | 2x6,4 |

| *Poids (kg) | 1800 | 2645 | 4092 |

Les valeurs de capacité sont données à titre indicatif, les résultats peuvent varier en fonction de la granulométrie de l'alimentation, de la teneur en limon et en argile, de la densité, de la quantité d'eau utilisée, de la configuration de l'équipement et de l'application. Les poids indiqués ne comprennent pas le moteur d'entraînement, les pieds de support, la plate-forme de maintenance, les goulottes d'entrée et de sortie.

Cribles De Déshydratation Galérie

Qu'est-ce que c'est Cribles De Déshydratation?

Tout matériau qui entre en contact avec l'eau se mouille. Les matériaux doivent être lavés ou transportés sous forme de concentré et de déchets de poudre lors de l'enrichissement du minerai pour la production d'agrégats et de sable nécessaires à la production de béton prêt à l'emploi dans les installations de préparation du minerai et dans le secteur de la construction.

Après un certain stade, le sable lavé doit être épuré de l'eau libre avant d'être utilisé dans un concentré aqueux, pour le transport ou pour le processus suivant. Les procédés de déshydratation permettent d'éliminer l'eau libre des mélanges liquide-solide à l'aide de cribles.

Types de Cribles De Déshydratation

Comment Cribles De Déshydratation travailler?

Avantages de l'utilisation Cribles De Déshydratation

Cribles De Déshydratation les processus/applications

Après avoir lavé le sel, l'argile, la chaux et les déchets de concentré, les déchets, le charbon, le sable de mer ou de rivière, les cribles de déshydratation sont utilisés pour éliminer l'eau libre du matériau.

Les cribles de déshydratation sont également utilisés pour le stockage à sec des déchets produits par les installations de préparation et d'enrichissement des minerais, ou avant la déshydratation.

Quels sont les matériaux transformés à l'aide de Cribles De Déshydratation

Quels sont les critères clés pour choisir le bon équipement Cribles De Déshydratation

Les solides contenus dans la boue alimentant le crible de déshydratation sont expulsés vers le haut et l'avant grâce à une force g considérable, par le biais d'un mouvement linéaire créé par des moteurs vibratoires à contre-rotation.

Ils constituent un équipement simple, peu coûteux et efficace pour éliminer l'humidité des matériaux solides afin de les rendre transportables.

Les cribles de déshydratation peuvent être utilisés dans différentes industries.

Ils améliorent la qualité des produits en réduisant leur teneur en humidité.

Les cribles de déshydratation aident à respecter les réglementations environnementales en minimisant la quantité d'eau perdue.

Les cribles de déshydratation peuvent être utilisés dans différentes industries.

Ils améliorent la qualité des produits en réduisant leur teneur en humidité.

Les cribles de déshydratation aident à respecter les réglementations environnementales en minimisant la quantité d'eau perdue.

Les cribles de déshydratation éliminent rapidement l'eau libre du matériau et réduisent son humidité à un niveau qui peut être transporté, utilisé ou séché sur des convoyeurs à bande.

Après avoir lavé le sel, l'argile, la chaux et les déchets de concentré, les déchets, le charbon, le sable de mer ou de rivière, les cribles de déshydratation sont utilisés pour éliminer l'eau libre du matériau.

Les cribles de déshydratation sont également utilisés pour le stockage à sec des déchets produits par les installations de préparation et d'enrichissement des minerais, ou avant la déshydratation.

Les cribles de déshydratation sont utilisés pour éliminer l'eau libre du matériau après le lavage du sel, de l'argile, de la chaux et des déchets provenant du concentration, des déchets, du charbon, du sable de mer ou de rivière.

Le crible de déshydratation fonctionne entre 0 et 5 degrés avec une pente ascendante. La direction, l'amplitude et la fréquence des vibrations sont sélectionnées en fonction de la taille du solide à séparer de l'eau et du résultat souhaité du processus. Si le débit du liquide+solide à déshydrater est trop élevé, l'eau s'écoulera sur le crible à côté du matériau sans passer par le crible pendant le processus de déshydratation, ce qui va à l'encontre de l'objectif de cette opération. L'utilisation de plusieurs cribles de déshydratation côte à côte peut résoudre ce problème, mais dans ce cas, le processus de déshydratation n'est pas rentable et il convient donc d'augmenter la densité de la pulpe en soumettant le mélange solide+liquide à un traitement cyclonique avant de le traiter avec un crible de déshydratation.L'ouverture du crible doit être sélectionnée en fonction de la taille de la matière à déshydrater. Pour sélectionner le bon crible de déshydratation, des critères tels que la capacité, la granulométrie de l'alimentation et le pourcentage d'eau doivent être pris en considération.