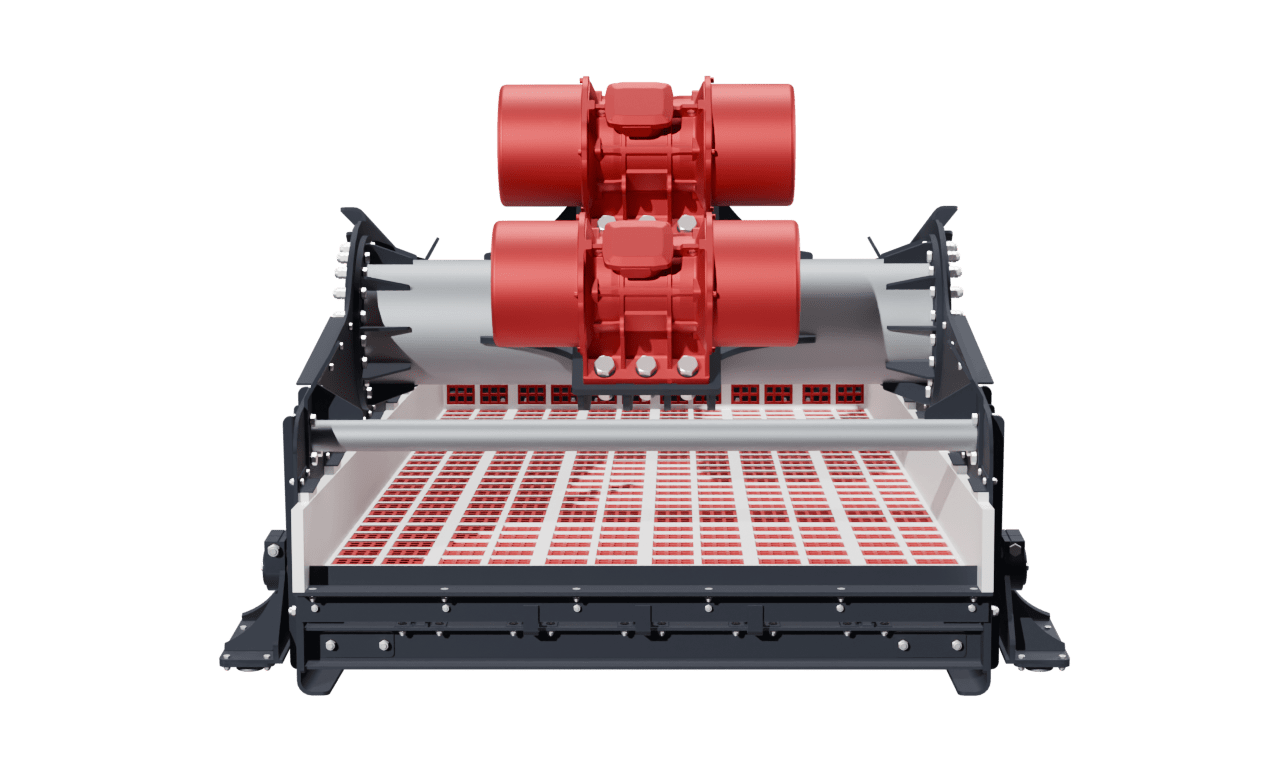

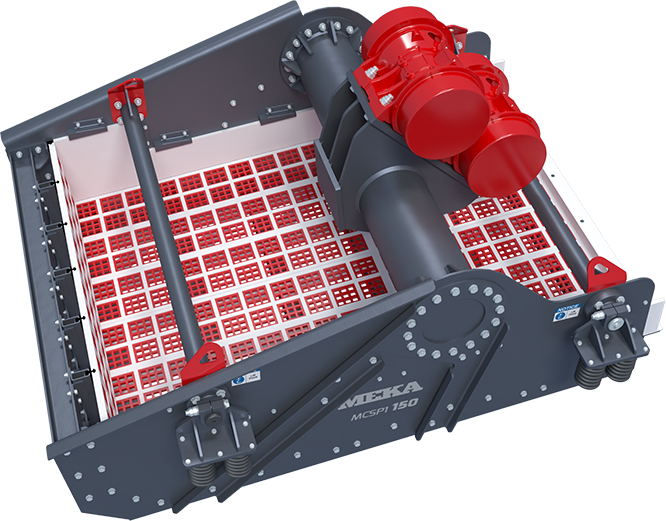

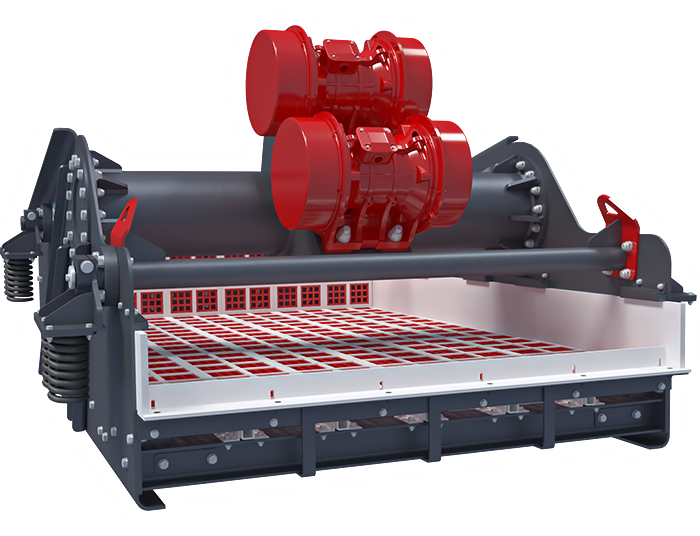

Dewatering Screen

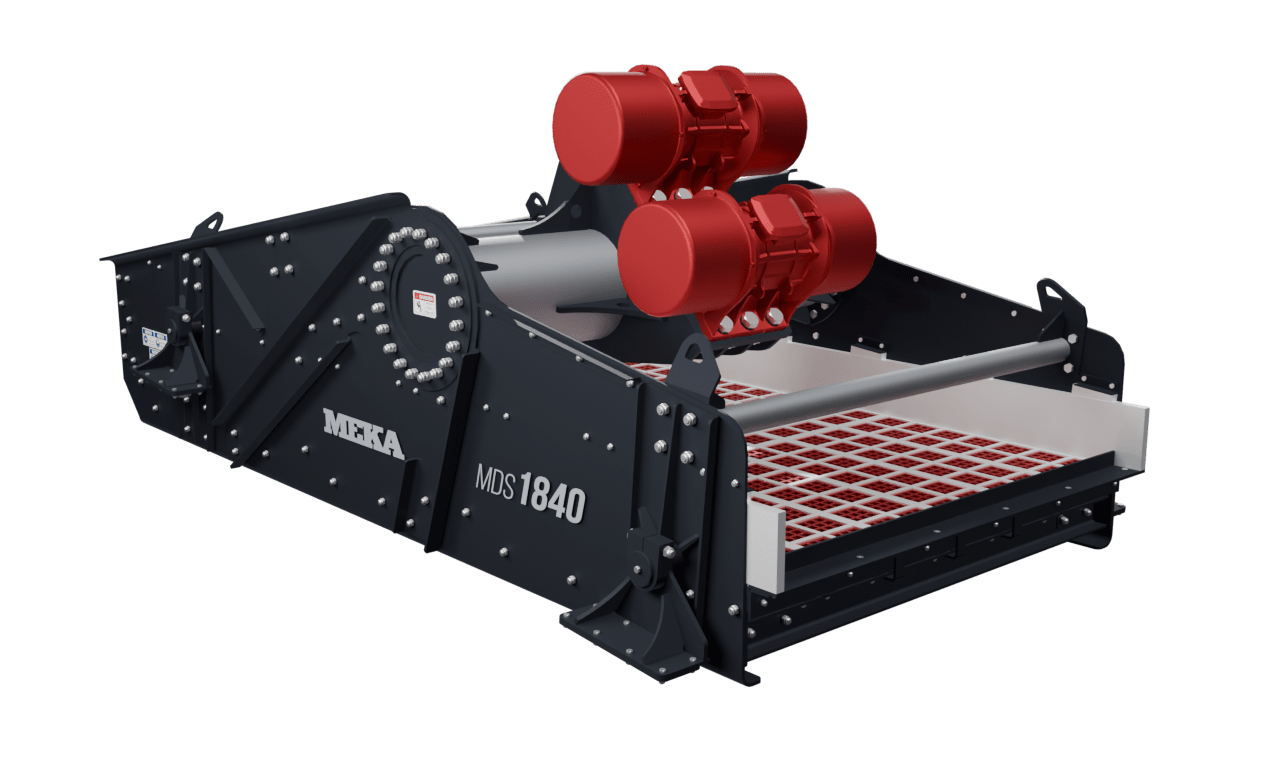

Dewatering screens are typically single deck, adjustable incline, linear motion screens utilized to dewater fine aggregates prior to stockpiling. They are typically fed with a sand and water slurry with a maximum feed size of 10 mm (3/8”), utilize polyurethane screen media ranging from #10 – #60 mesh and will typically produce a finished product with an approximate moisture content of 8– 15 percent by weight. Available MDS series screen sizes range from 1200 mm (4’) wide x 2400 mm (8’) long to 1800 mm (6’) wide x 4000 mm (13’) long with processing rates up to 210 mtph (230 stph) on a single unit.

Applications

- Sand

- Aggregates (construction)

- Construction and Demolition Waste

- Iron Ore

- Coal

- Other Mineral Ores

Why MEKA Dewatering Screen?

- Maximum dewatering of your sand product

- High frequency vibrating motors ensure a high power to area ratio ensuring the most efficient dewatering of your sand product.

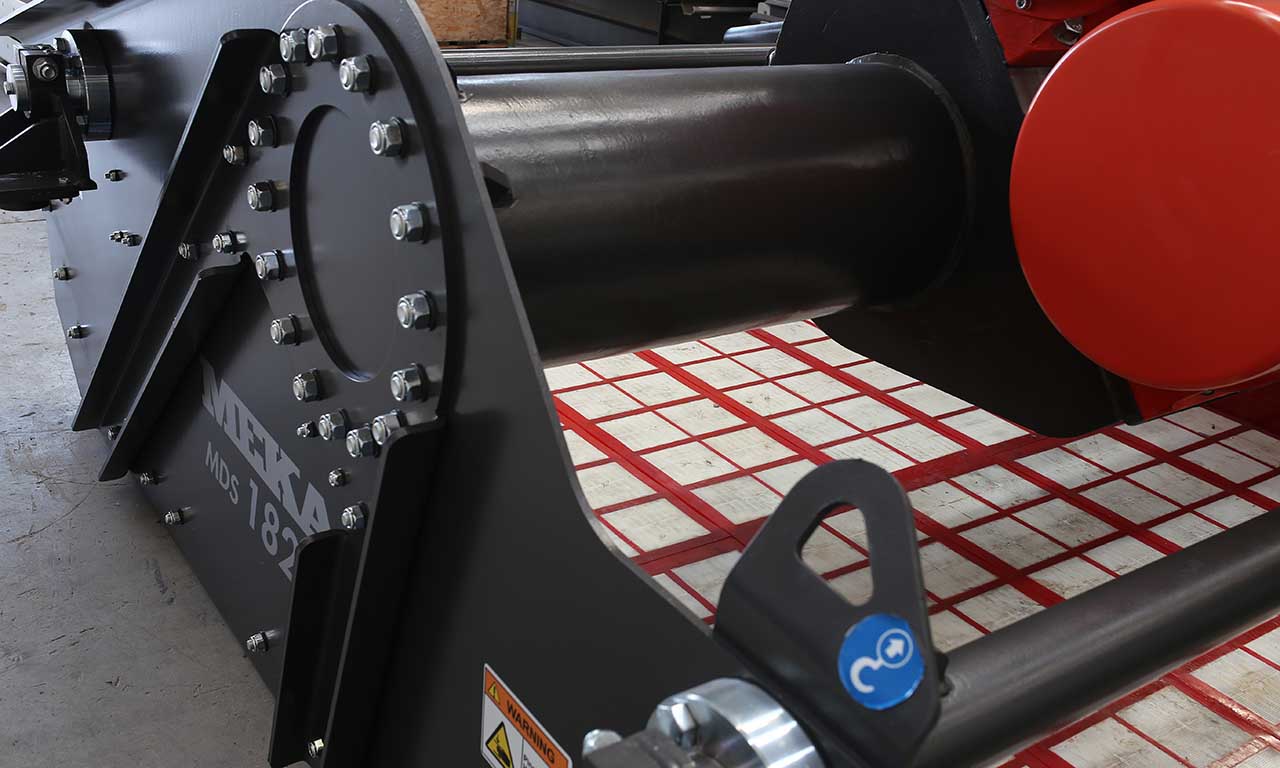

- Maximum wear resistance

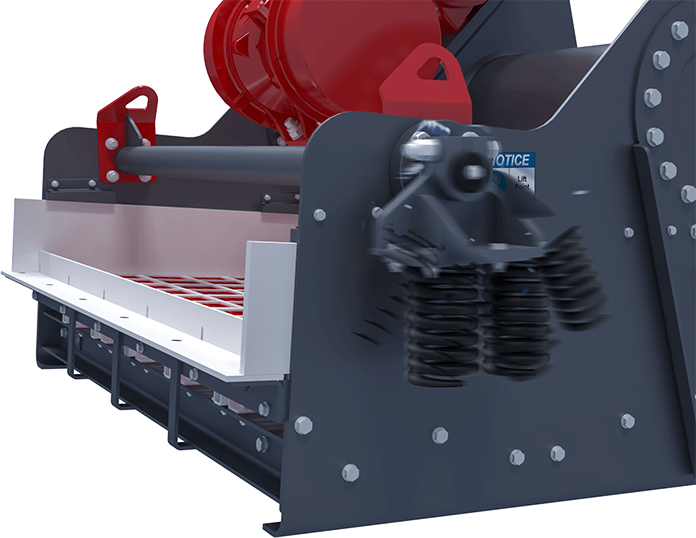

- Replaceable polyurethane side wall protection on the MDS screen minimises material on steel contact, reducing wear and increasing the working life of the machine. Fully rubber lined discharge chutes for maximum wear resistance

- Efficient grading of your sand product

- Deeper bed depth allows screens to remove more moisture and retain highest percentage of saleable product

- Ease of maintenance

- Modular Polyurethane non-bolted panels as standard for ease of maintenance.

MEKA Dewatering Screen Advantages

-

MEKA Dewatering Screen Download Catalogue

Dewatering Screen Technical Specifications

MDS 1224 |

MDS 1824 |

MDS 1840 |

|

| WidthxLength (mm) WidthxLength (feet) | 1200x2400 3x8 | 1800x2400 6x8 | 1800x4000 6x13,1 |

| Number of Decks Number of Decks | 1 1 | 1 1 | 1 1 |

| Power @50Hz (kW) Power @50Hz (HP) | 2x2,88 2x3,86 | 2x7,35 2x9,85 | 2x6,1 2x8,18 |

| Power @60Hz (kW) Power @60Hz (HP) | 2x3,9 2x5,22 | 2x6,6 2x8,85 | 2x6,4 2x8,58 |

| *Weight (kg) *Weight (lbs) | 1800 3698 | 2645 5831 | 4092 9021 |

* Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes.

What is Dewatering Screen?

Any material that comes into contact with water will get wet. Material needs to be washed or transported as concentrate and waste pulp in the enrichment of the ore for the production of the aggregate and sand necessary for ready-mixed concrete production in ore preparation facilities and in the construction sector.

After a certain stage, washed sand must be purged of free water prior to use in aqueous concentrate, for transportation or for the following process. Dewatering processes remove the free water from liquid-solid mixtures through the use of screens.

They are low cost and effective simple equipment to remove moisture from solid materials so that they can be transported by belt conveyors.

Dewatering screen can be used in variety of different industries.

Improve the product quality by reducing moisture content.

Dewatering screens assist in complying with environmental regulations by minimizing the amount of water losses.

After washing the salt, clay, lime and waste from concentrate, waste, coal, sea or river sand, dewatering screens are used to remove the free water from the material.

Dewatering screens are also used for the dry storage of waste produced by ore preparation and enrichment facilities, or before dehydration.