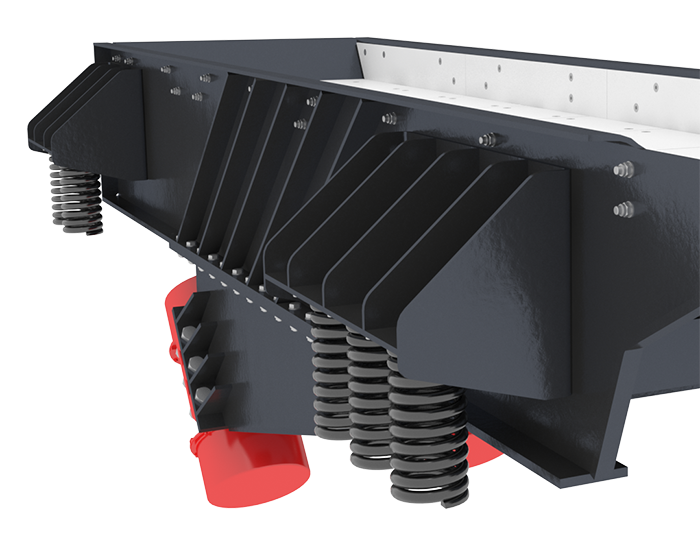

Titreşimli besleyici gövdesi yaylar üzerine konumlandırılır veya asılır. Besleyici, üzerine monte edilen vibromotorlarla tahrik edilir. Bu vibromotorlar sayesinde elde edilen lineer titreşim hareketi ile düzgün malzeme beslenmesi sağlanır.

Titreşimli Besleyici

MVF Serisi

Titreşimli Besleyici

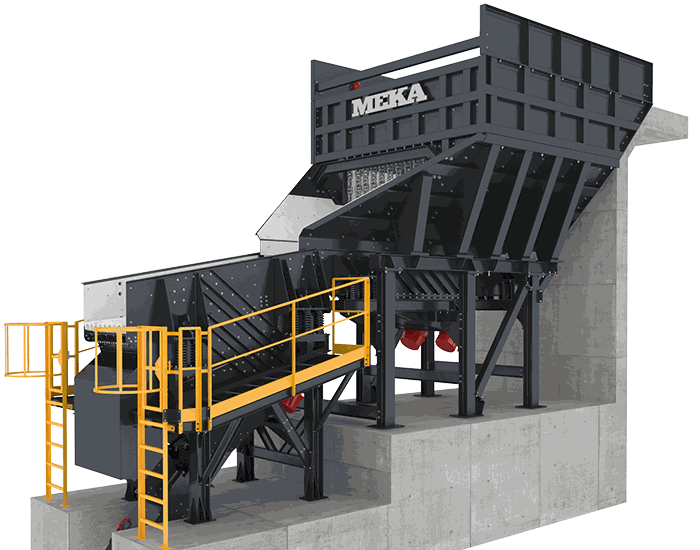

Titreşimli besleyiciler, sekonder ve tersiyer kırma aşamalarında malzemenin kırıcılara düzenli ve yüksek kapasitede beslenmesini sağlarlar. Uygulamaya göre, helezon yaylar ile askılı tip veya destek yayları üzerine monteli tipleri imalat programımızda bulunmaktadır.

Uygulamalar

Titreşimli Besleyiciler (MVF) sekonder ve tersiyer kırma aşamalarında malzemenin yüksek kapasiteli beslenmesini sağlarlar. Kırma eleme tesislerinde maksimum verim elde edilmesine yönelik olarak; bunker altında, açık stok altı tünel uygulamalarında, kırıcı giriş ve çıkışlarında malzemenin düzenli beslenmesinde kullanılırlar.

Neden MEKA Titreşimli Besleyici?

- Çok yönlüdür

Uygulamaya göre, helezon yaylar ile askılı tip veya destek yayları üzerine monteli tipleri kullanılabilir. - Yüksek kapasitelidir

Yüksek kaliteli vibro motorlar sayesinde, çok ince ve kaba malzemelerin verimli bir şekilde beslenmesini sağlarlar. - Geniş imalat programı

Tasarımları ve geniş imalat programı, değişik ihtiyaçlara uygun titreşimli besleyici seçimini sağlamaktadır.

Titreşimli Besleyicilerin Teknik Özellikleri

MVF 6515 |

MVF 8517 |

MVF 1020 |

MVF 1220 |

MVF 1520 |

MVF 1020C |

MVF 1320C |

MVF 1520C |

|

| Genişlik x Uzunluk (mm x mm) Genişlik x Uzunluk (inch x feet) | 650x1500 25''x5' | 850x1700 33''x5⅟2'' | 1000x2000 39''x6⅟2' | 1200x2000 47''x6⅟2' | 1500x2000 59''x6⅟2' | 950x2025 37⅟2"x6⅟2' | 1300x2000 51³/16"x6³/5' | 1450x2025 51⅟16"x6⅟2' |

| Güç @50hz (kW) Güç @50hz (HP) | 2x0.9 2x1.2 | 2x1.96 2x2.8 | 2x1.96 2x2.8 | 2x2.2 2x2.95 | 2x3.2 2x4.3 | 2x1.96 2x2.62 | 2x2.2 2x2.95 | 2x2.2 2x2.95 |

| Güç @60hz (kW) Güç @60hz (HP) | 2x0.9 2x1.2 | 2x2.3 2x3 | 2x2.3 2x3 | 2x2.3 2x3 | 2x3 2x4 | 2x2.3 2x3 | 2x2.3 2x3 | 2x2.3 2x3 |

| *Kapasite (mtph) *Kapasite (stph) | 100-180 110-198 | 180-275 198-302 | 220-400 242-440 | 250-500 275-550 | 300-600 330-660 | 220-400 242-440 | 300-550 330-605 | 400-650 440-715 |

| Maksimum Besleme Boyutu (mm) Maksimum Besleme Boyutu (inch) | 200 8 | 260 10 | 300 12 | 330 13 | 460 18 | 300 12 | 400 16 | 460 18 |

*Belirtilen eğimde ve 1,6 t/m³ veya 100 lbs/ft³ ağırlığındaki malzeme için. Kapasite değerleri yalnızca gösterge niteliğindedir ve yalnızca besleyici boyutuna değil, aynı zamanda besleyici eğimine, ilerleme derecesine vb. de bağlıdır.

-

MEKA Titreşimli Besleyici Kataloğunu İndirin

MEKA Titreşimli Besleyicilerin Üstünlükleri

Titreşimli Besleyiciler Nedir?

Titreşimli besleyiciler, ikinci ve üçüncü aşamalardaki kırıcıların düzenli beslenmesi için kullanılır.

Titreşimli Besleyiciler Nasıl Çalışır?

Titreşimli Besleyiciler Kullanmanın Avantajları

Titreşimli Besleyiciler Kullanım Alanları

Hangi Malzemeler Titreşimli Besleyici Kullanarak İşlenir

Bakım ve İşletme için İpuçları

Farklı kullanım amaçlarının yanı sıra öncelikle sekonder ve tersiyer aşamalardaki kırıcıların düzenli beslenmesini sağlar.

Titreşimli besleyiciler sekonder ve tersiyer aşamada kullanılan ekipmanlardır. Madencilik, agrega veya geri dönüşüm gibi çok çeşitli uygulamalarda kullanılmak üzere farklı kapasiteler için farklı genişlik ve uzunluklarda türleri mevcuttur. Tipik olarak kırıcıların bir bunker aracılığıyla düzenli ve sürekli beslenmesini sağlarlar. Tünel içindeki konveyör bantlarına düzenli besleme ile açık stok altındaki tünellerde yaygın olarak kullanılır.

Madencilik, taş ocakları, endüstriyel mineraller ve geri dönüşüm alanlarında geniş bir uygulama yelpazesinde kullanılır.

Tüm titreşimli ekipmanlarda ve diğer kırma ve eleme makinelerinde olduğu gibi, kullanıcı kitaplarında ayrıntılı olarak açıklanan günlük, haftalık ve aylık kontroller ve bakım prosedürleri izlenmelidir. Titreşimli besleyicilerin bakımı/işletimi için:

Aşınma ve yıpranma kontrol edilmeli ve uzun bir çalışma ömrü sağlamak için aşınmış parçalar değiştirilmelidir. Besleyicinin beslenen malzeme ile temas eden yüzeylerindeki aşınma ve yıpranma ana gövdeye ulaşmadan önce aşınmış plakalar değiştirilmelidir. Özellikle besleyici tabanında korozyon olup olmadığı kontrol edilmeli ve malzeme akışını engelleyebileceğinden kaynaklı onarımlardan kaçınılmalıdır.

Titreşimli besleyicilerin gövdesinde gevşek sabitleme olmamalıdır. Titreşim sistemi ve vibromotor bağlantılarının kontrolü düzenli olarak yapılmalıdır.

Yaylar ve kauçuk sönümleme takozları periyodik olarak kontrol edilmeli ve gerekirse değiştirilmelidir.

Dünya Genelindeki Projelerimizi Keşfedin

Bizimle İletişimde Kalın

YENİ PROJELERİMİZ VE ÜRÜNLERİMİZ HAKKINDA BİLGİ SAHİBİ OLMAK VE MEKA’DAN HABERLERİ İLK ÖĞRENEN OLMAK İÇİN E-BÜLTEN’İMİZE HEMEN ABONE OLUN!