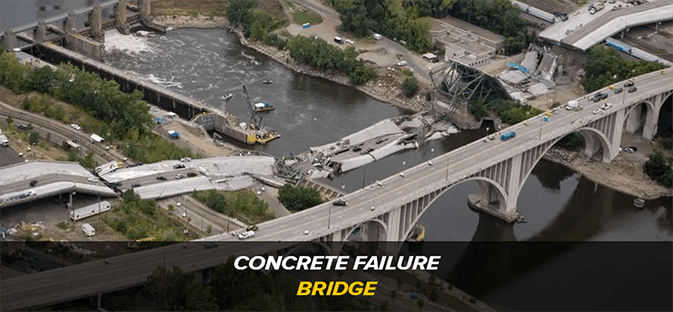

Case Study: Concrete Failure - Bridges

Bridges are one of the most important structures of transportation networks. No-one knows how the bridge concept really began but early man would have used fallen trees, stepping stones, and other naturally occurring materials to cross geographical barriers. The use of reinforced probably started in 1870 when the iron was embedded in , but it was not until the first decade of the 20th century that reinforcement, as we know it today, was introduced. Then they were developed to provide a safe transportation.

Researches have shown that most of the bridges collapse due to hydraulic reasons such as floods, carvings etc. because hydraulic principles are not considered in the design phase. Only static and reinforced calculations are often insufficient when the bridge design is the concern. The most important reason for the failure of bridges is a mixture of factors that will not cause a bridge to collapse by individual influence. However, when they all happen, they cause them to collapse.

Nowadays, production with long durability has started to gain importance besides focusing on high strength. Also should provide both strength, chemical and physical strength required for as long as it is in service.

The most important chemical and physical factors which affect durability and strength are as follows;

Chemical effects:

- Sulphate attack

- Alkali-Silica Reactiop

- Sea Water effectp

- Acid attacp

- Carbonatiop

- Chlorine attacp

- Freeze-Thaw Effecp

- Weap

Sulphate attack: Sulphate attack affects impermeability negatively and causes a voided structure. It creates deep cracks on the outer surface of the , damaging the rust and causing corrosion of the reinforcing steel. It reduces the strength of and also causes aesthetic problems. The presence of sulphates in the cement matrix can cause a chemical reaction. Sulphates are usually caused by sulphate or by aggregates which exposed to groundwater, pollutants, seawater, decomposable organic matter or industrial wastes. Another source of sulphate is the recycled used as aggregate.

All strong acid species such as sulfuric acid will affect cement hydrates, decaying organic substances can release sulfuric acid in poorly preserved structures. Decomposition of due to chemical salts similar to decay based on acidic salts. the cement matrix is affected by the salts that it is exposed to. Ammonium chloride is an example of salts that reduce the strength of Reinforced steel corrosion is the most important cause of indirect deterioration.

Alkali-Silica Reaction: The alkali-silica reaction (ASR), is the reaction of reactive silica in aggregates and solution of hydroxyl ions within voids. This reaction causes the formation of a gel which expands with the effect of moisture in . The increase in volume due to the swelling leads to cracks in the . The alkali-silica reaction is a complex chemical reaction, which affects the durability of and damages many reinforced structures.

Freeze and thaw effect: If the is exposed to frost immediately after mixing, frozen water volume increases by about 9% and it is moved toward the gaps in the In this formation, the solid particles in the fresh are replaced. As a result of formation, the solid particles in the fresh are replaced. As a result of the displacement, the bond between the aggregate granules and the mortar breaks.

Erosion effect: liquids with suspended particles inside them are abraded by drawing the surface at high speed which is mostly found in water structures and pipes. The intensity of activity depends on the number of solid particles, shape, hardness and flow rate of water. If the quantities and sizes of the solid granules are low, if the water flow rate does not exceed 1.8 m / s, then the erosion is negligible.

Wear effect: If. However, in order to be resistant to friction, such as C30, C40 should be preferred. Using abrasion resistant aggregate in production, using vacuum (low, water/cement ratio), using additives or paint which reduce friction, using surface hardener materials on the surface are other precaution.

Sea water effect: Different species and amounts of salt were exist in marine waters. The reaction that takes place when the sulphates in the marine waters enter the the abrasive effect created by the sulphates in sea water is not as severe as the effect of sulphates in the ground and underground waters. The presence of chloride ion in the sea water, products resulting from sulphate reactions which lead to less expansion.

Carbonation effects: The rusting of the steel is prevented by the slaked lime which is present in the (Ca (OH2)). However, this positive feature may disappear as a result of a chemical process called carbonation. Especially, Slaked lime combines with carbon dioxide (CO2) existing in the air to form limestone. This combination reduces the pH of the and causes corrosion of the reinforcement. Carbonation continues from the surface to the inner zone with decreasing speed. For this reason, it is concentrated in the shell layer. Unfortunately, because of a few centimeters thickness of shell layer reinforce steel begin to rust.

Natural disasters:

Flood: Today's changing climate and extreme weather events cause more flood which damaged the bridges. Rivers strongly pushed trees, buildings and collects against the bridge during a flood, leads to the washing of the foundation which causes failure of structural elements.

Earthquakes: The bridges damages caused by earthquakes can lead to big problems. People on and under the bridge are in danger during the earthquake, bridges are great of importance to ensure that transportation can continue in emergency situations such as the earthquake. Typical damages caused by earthquakes in reinforced bridges can be grouped as follows;

Movement and settlement of support, slipping of beams from the support, deflection of mid-span of beams, collapse and damage of columns due to inadequate stirrup, collapse or damage of the bridge foundation due to movement and settlement of soil.

Fire: Before the construction materials and steel become more commonly used because of its effective and lower cost, bridges were usually built from wood. For this reason, fires were a common cause of bridge collapse. Today, most bridges are constructed using steel and therefore the fire is much less damaging to reinforced bridges.

Design and Manufacturing Defects: Significant number of highway and railway bridges in use today have nearly completed their design life or in the midst of it. Most of them were designed and built when bridge design codes did not have proper fatigue design provisions. Also, design and construction are uniquely influenced by surrounding geology, the volume of traffic, local weather condition, available construction materials and even the desired aesthetics. Bridge design and engineering advanced significantly in the latter half of the past century because bridge designers and engineers applied lessons learned from a series of bridge failures.

However, better design and engineering have clearly not eliminated the risk of the bridge collapse. The best way to avoid bridge failures is to expect them to happen and plan for them.

Vural MERCAN

Civil Engineer

References:

BMİ Bridge Masters Common reasons for bridge failures

Christopher J. Friend, The Pennsylvania State University

Gerardus Cornelis Maria GAAL civiel ingenieur geboren te Alkmaar