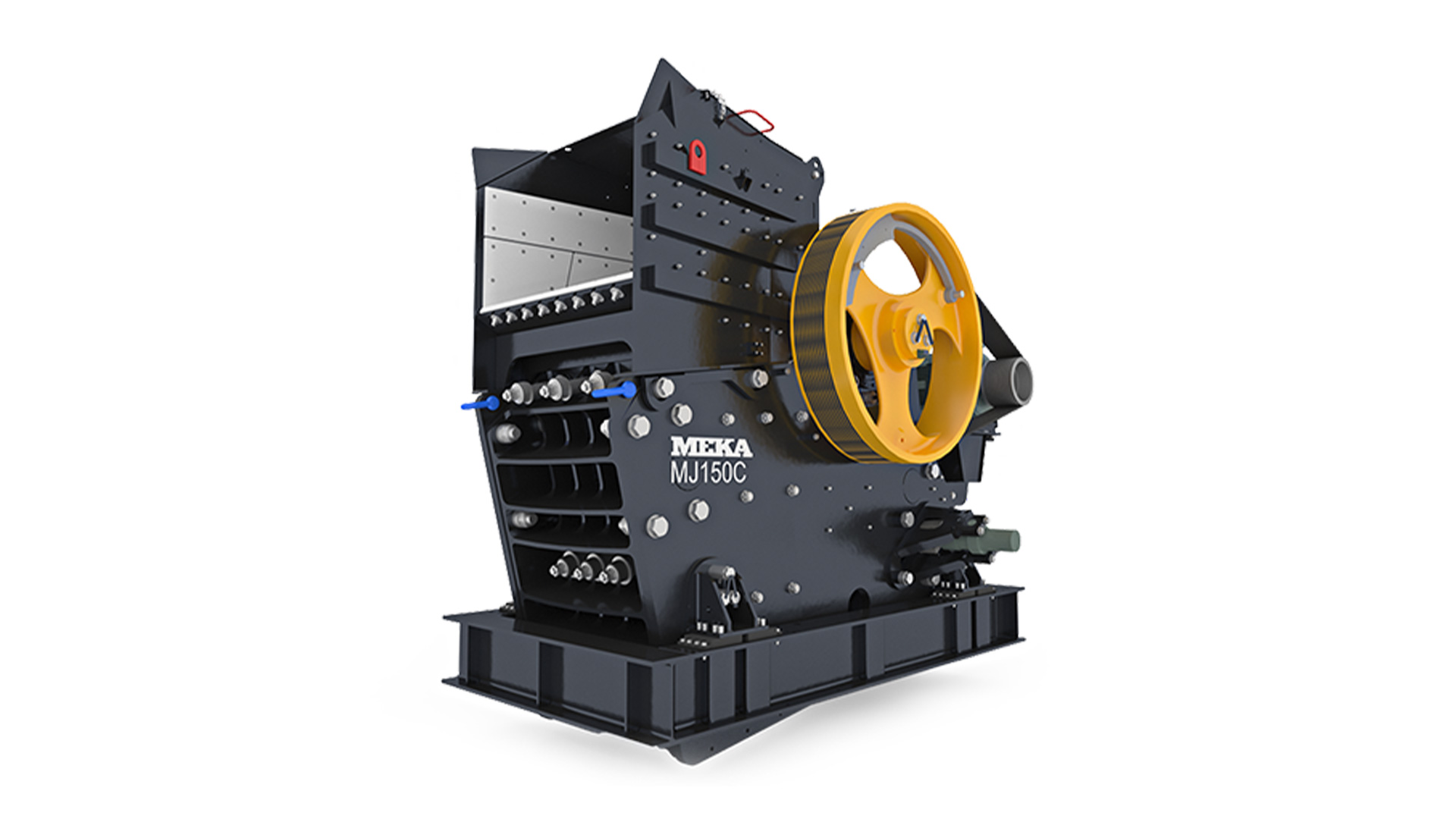

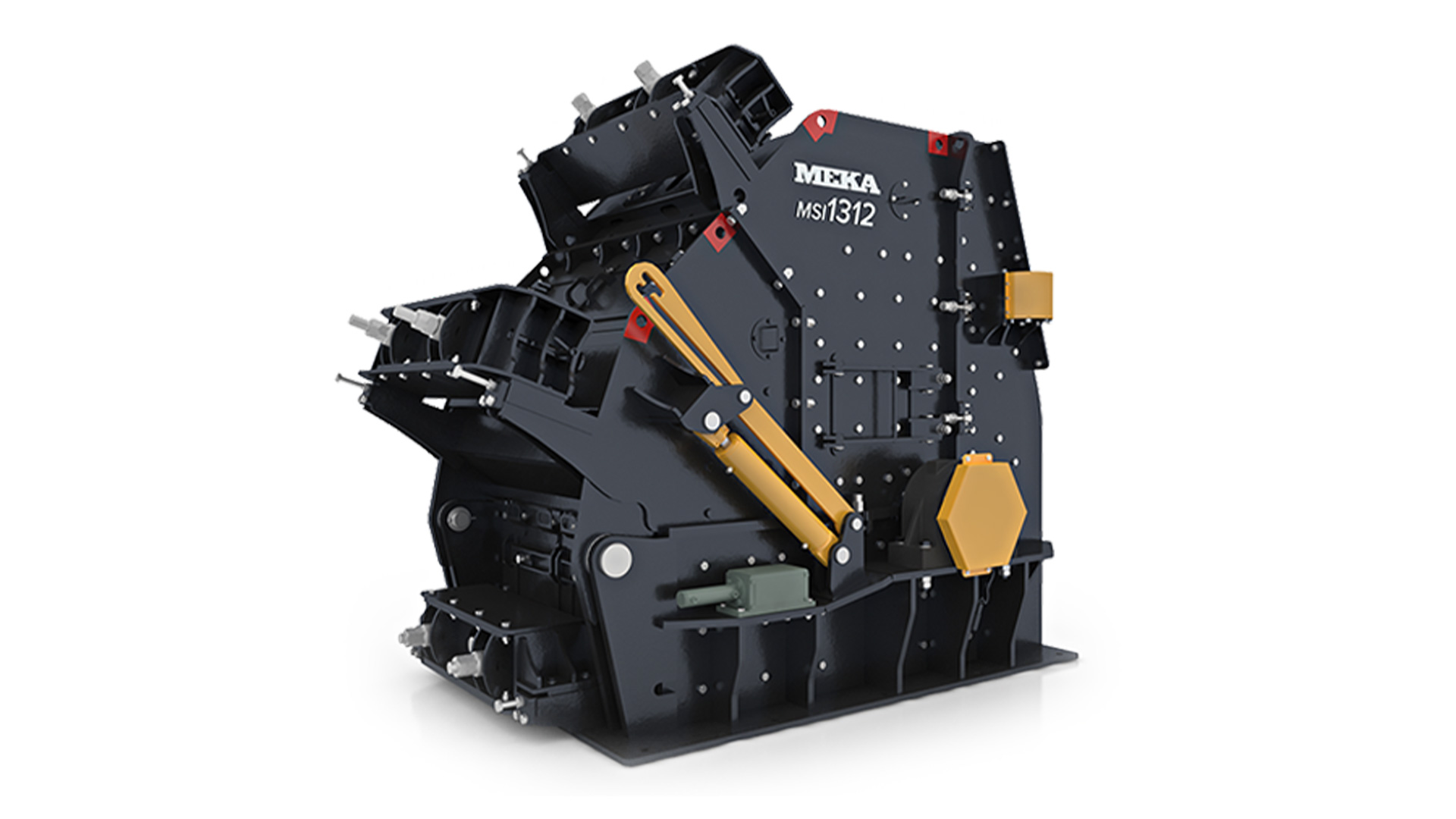

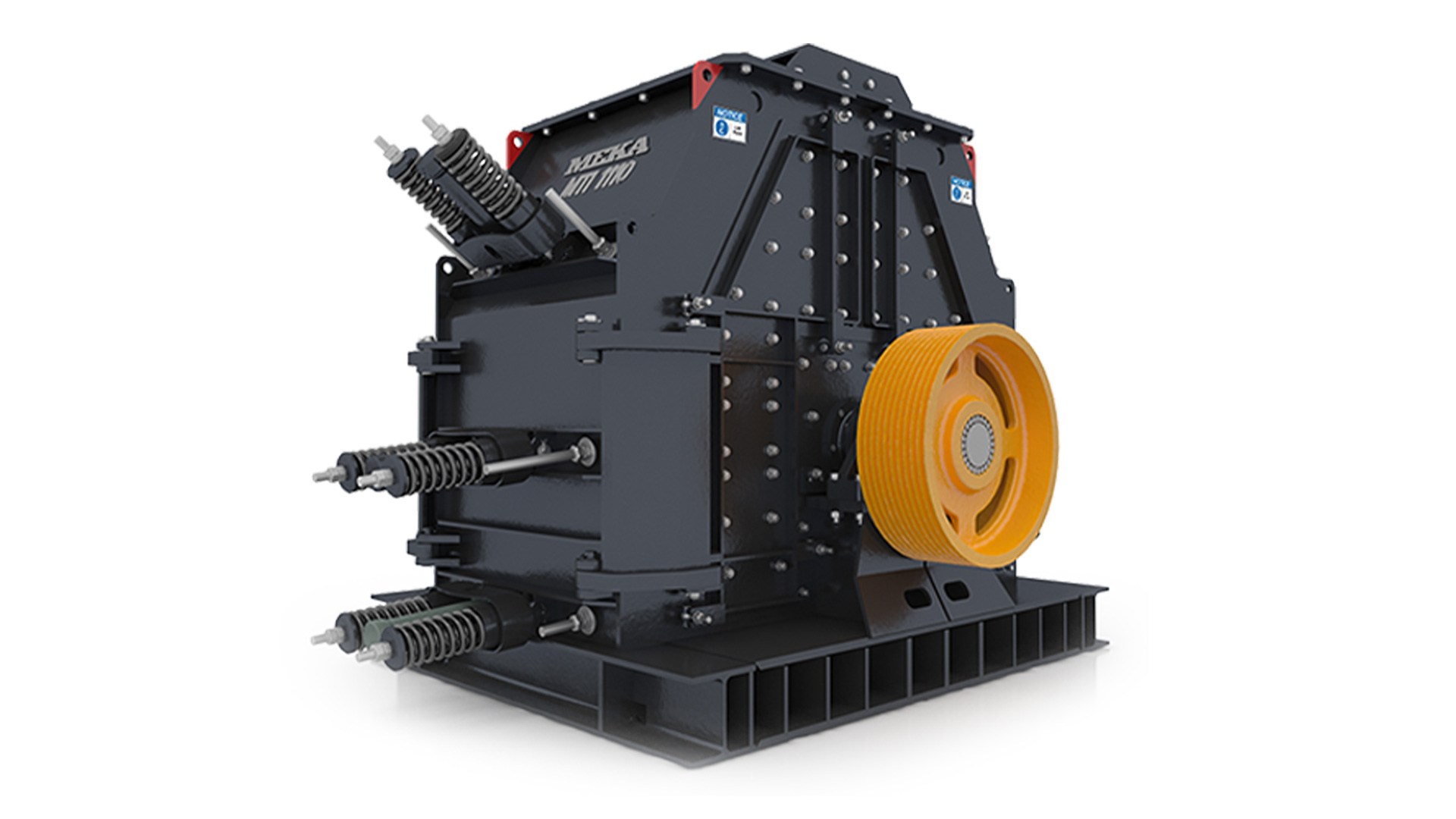

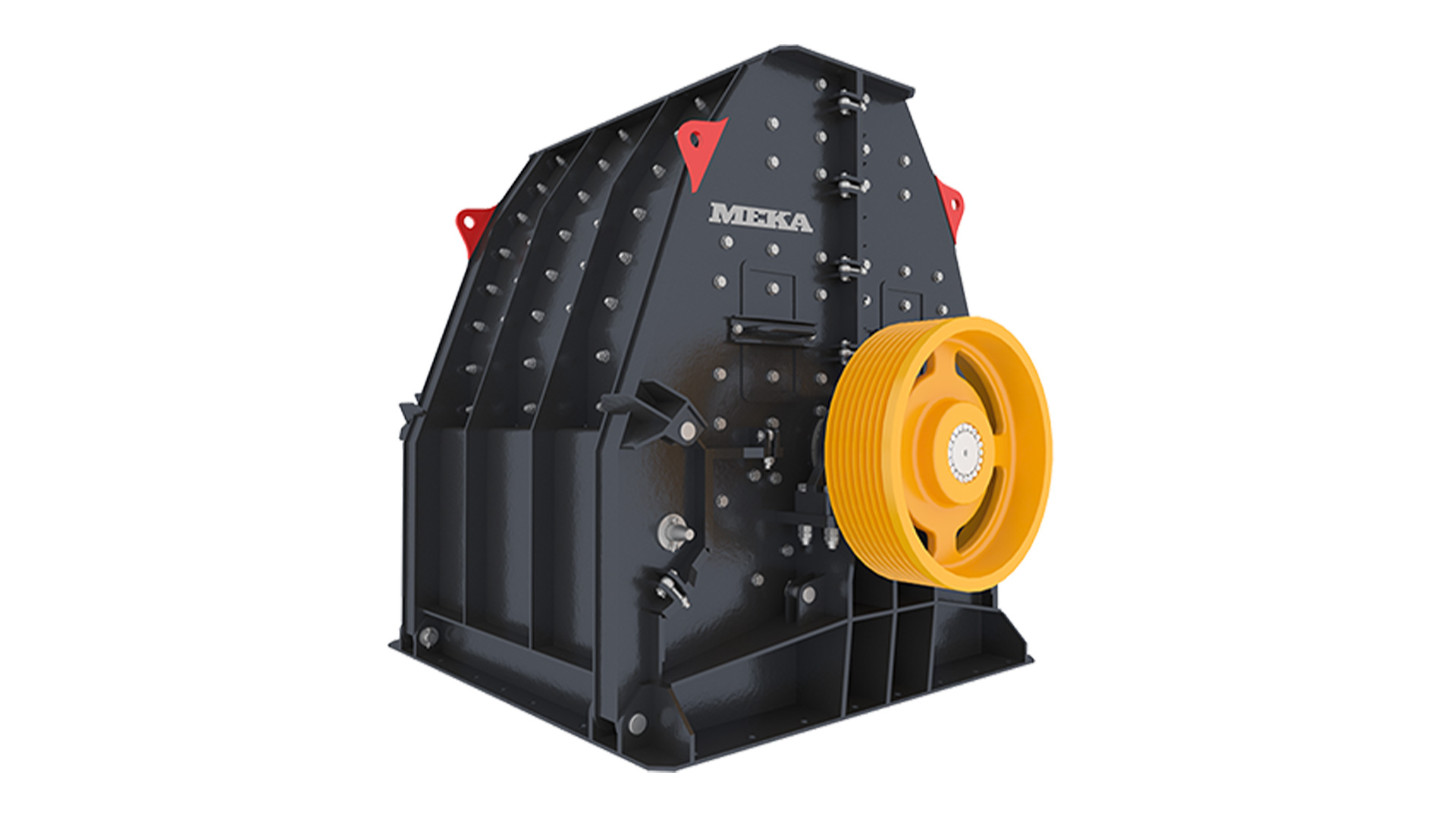

Crushers

For Aggregate Producers, Industrial Mineral Processing Plants and Various Mines

MEKA Crushing and Screening Technology serves all industries involved in size reduction of rock and minerals, meeting your specific requirements from single to mobile plants and complete rock processing plants, all supported by highly efficient after-sales service.