MEKA SCREENING EQUIPMENT

Economical Equipment with Exceptional Quality and High Screening Efficiency

Designed as a non-welded frame with adjustable vibration features for various material types and screening sizes, MEKA vibrating screens offer high-quality and dependable screening efficiency.

The screening process is just as important as the crushing itself. Screens, which are the heart of every quarry or mine, are used to classify materials both in different stages of the crushing process and in final product separation.

-

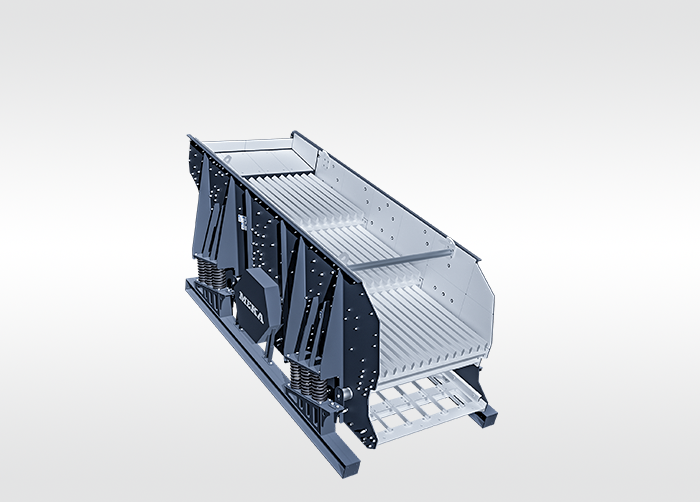

MEKA Horizontal Screens are a combination of quality, reliability, and performance; providing a long service life while operating under the most demanding applications.

-

MEKA MS inclined screens feature a unique combination of characteristics that result in high capacity and high screening efficiency, as well as long service life.

-

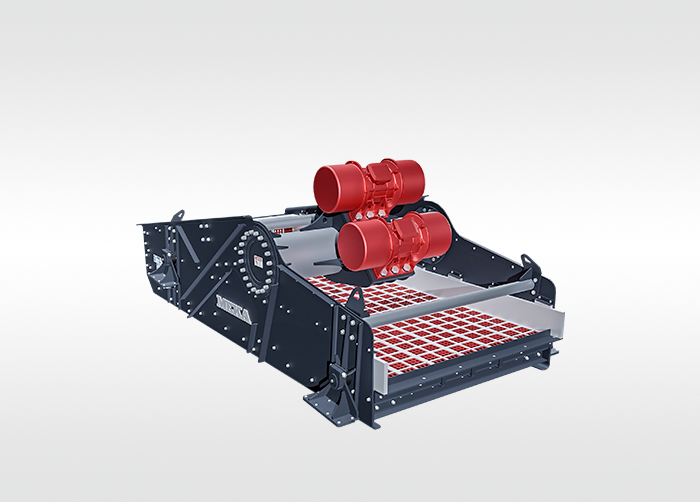

MEKA Grizzly Screens are specially designed for extra heavy-duty applications. Thanks to its two-deck structure operating under the effect of circular vibration, it provides efficient screening of both coarse and fine materials on a single body.

-

MEKA Dewatering Screens are designed to remove excess water from materials and minimize moisture content.

-

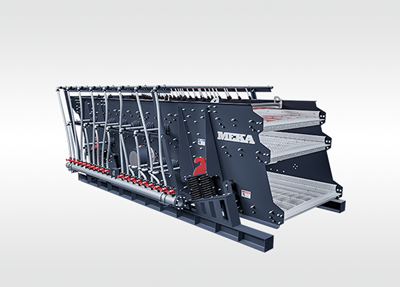

MEKA Scalper Screens are built with a robust, heavy-duty design for coarse material feeding and high tonnages

From Experience to Perfection

Let us solve all your screening equipment needs!

How much do horizontal screens cost?

Can I get a price quote?

Can I become a dealer for your equipment?

May I learn about your references for screening equipment in Europe?

How long does it take to deliver an inclined screen?

How can we calculate screen capacity?

And all your questions...

Let's move on to the next level. Contact us now by filling out the form.