Grizzly Screen

Applications

MGS Grizzly screens are widely used before the secondary crushing stage, where unwanted material needs to be thrown out as waste or where coarse fractions should be taken out as product. Additionally the facility for bypassing fines ahead of the secondary crusher maximizes the throughput at this stage.

Why MEKA Grizzly Screen?

- Massive Durability

Excel in extreme and abrasive conditions with unparalled ruggedness and resistance to wear

- Versatality

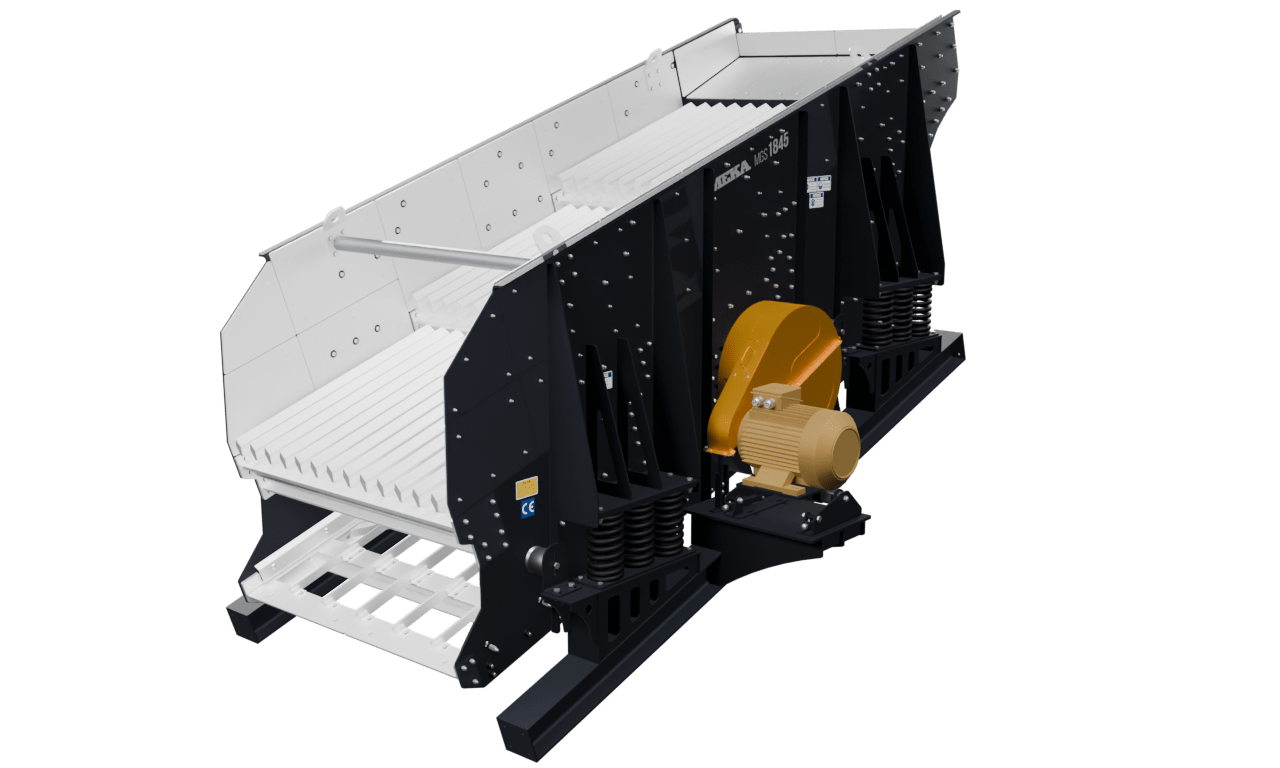

Fitted with grizzly bars on the top deck, can handle big, tough loads with ease

- Maximum efficiency

Adjustable counterweights in drive unit to assure proper screen stroke for each application.

- No weld side plates

MEKA's "no weld" policy on screen side plates eliminates the possibility of stress concentrations in heat affected zones.

MEKA Grizzly Screen Advantages

-

MEKA Grizzly Screen Download Catalogue

Grizzly Screen Technical Specifications

MGS 1440 |

MGS 1640 |

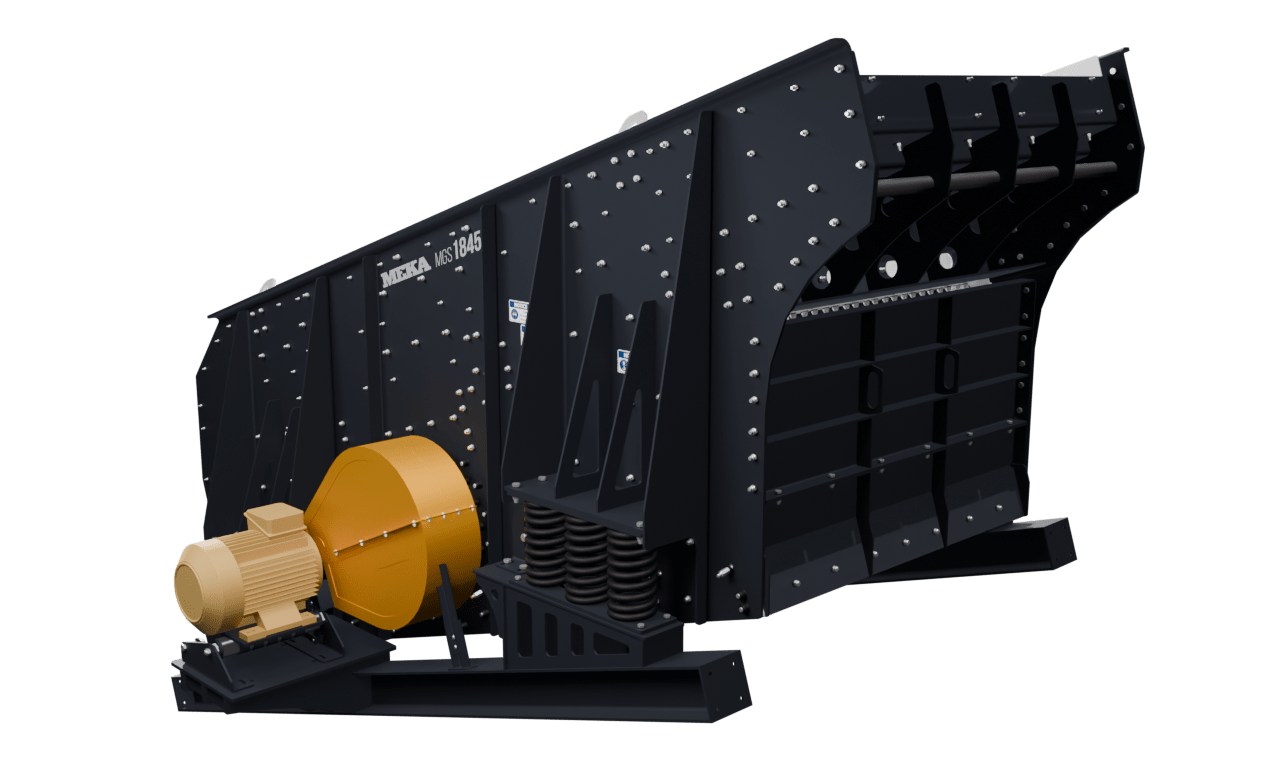

MGS 1845 |

|

| WidthxLength (mm) WidthxLength (feet) | 1400x4000 4⅟2'x13' | 1600x4000 5⅟4'x13' | 1800x4500 5⅟4'x13' |

| Number of Decks | 2 2 | 2 2 | 2 2 |

| Power (kW) Power (HP) | 22 30 | 30 40 | 37 50 |

| Length of Grizzly (mm) Length of Grizzly(inch) | 1000 39.4 | 1000 39.4 | 1500 59 |

| *Weıght (kg) *Weıght (lbs) | 8700 19180 | 9400 20723 | 12124 26729 |

* Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes.

What is Grizzly Screen?

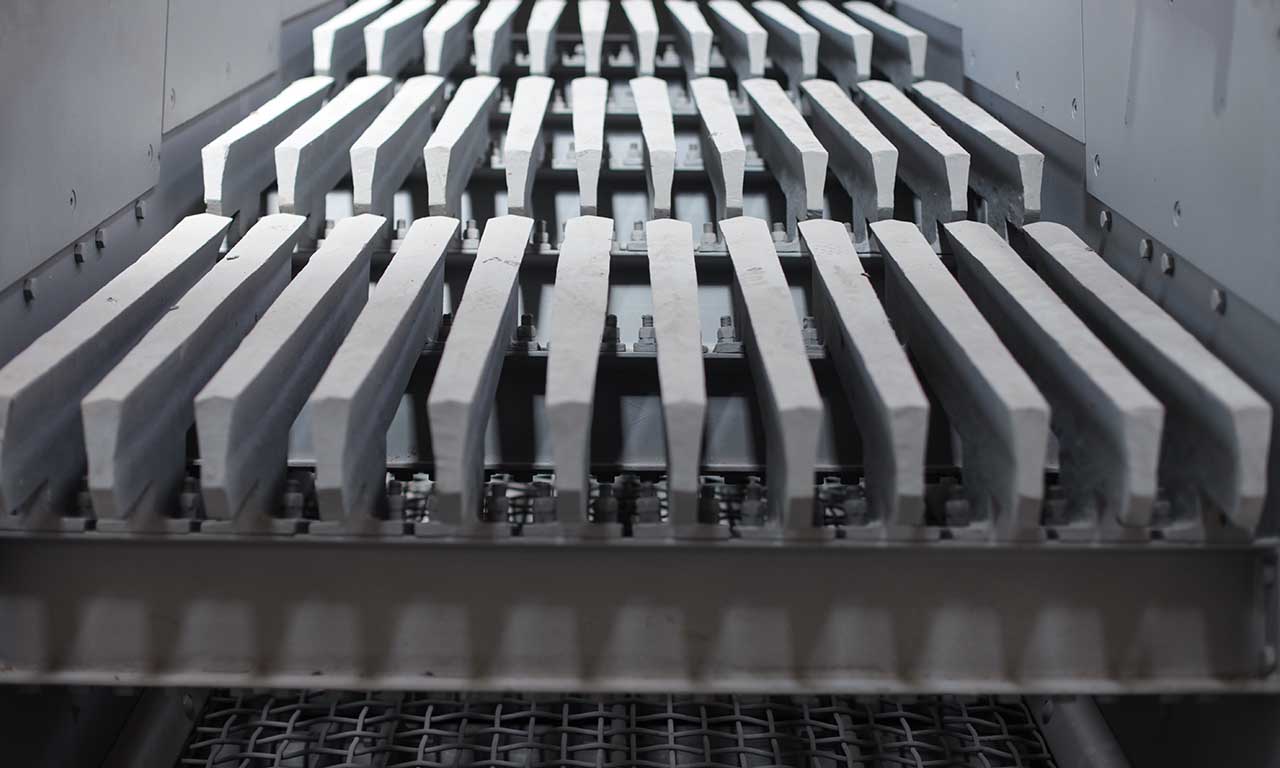

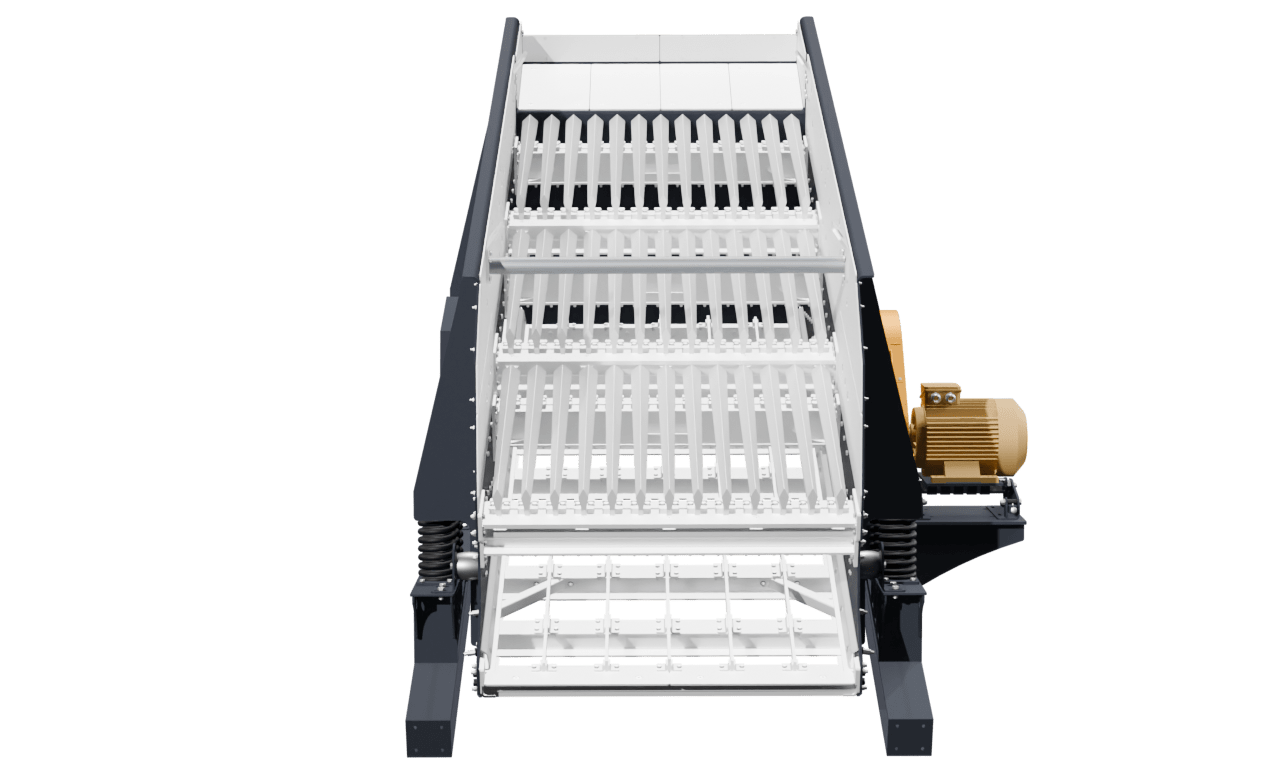

Grizzly screens are heavy duty inclined circular motion two decks screens. Top deck equipped with grizzly and bottom deck with wire mesh.

Generally, the top deck of the screen feeds the material to the downstream crusher , the material passing through the bottom deck is sent to the stockpile as waste or other purposes while the material between the two decks by-pass the crusher.

By removing unwanted material and bypassing the downstream crusher, productivity is increased and energy consumption is reduced: More plant capacity , less wear, less energy consumption in the downstream crusher.