-

Quarry Waste Recycling

Quarry Waste Recycling

MINIMISING WASTE, MAXIMISING USE

Each stage of the quarrying process produces by-products in the form of overburden, scalpings or crushed rock fines. Sub-economic materials currently being held in stockpiles across the world are defined as wastes because the material is heavily claybound or because of other inherent material characteristics and no market currently exists for them.

The ability of quarries to convert these wastes into approved products has been hampered by the lack of flexibility, affordability and sustainable techniques available. However, if processed with the right technology these by-products still have the potential to produce quality products for applications such as surface dressing, concrete production or asphalt.

MEKA team has years of experience in material processing, waste management and the quarrying industry and choosing MEKA as your solution partner will provide your Quarry Group with a unique, unrivalled and unlimited opportunity to substantially improve on your operations and profitability.

Each stage of the quarrying process produces by-products in the form of overburden, scalpings or crushed rock fines. Sub-economic materials currently being held in stockpiles across the world are defined as wastes because the material is heavily claybound or because of other inherent material characteristics and no market currently exists for them.

The ability of quarries to convert these wastes into approved products has been hampered by the lack of flexibility, affordability and sustainable techniques available. However, if processed with the right technology these by-products still have the potential to produce quality products for applications such as surface dressing, concrete production or asphalt.

MEKA team has years of experience in material processing, waste management and the quarrying industry and choosing MEKA as your solution partner will provide your Quarry Group with a unique, unrivalled and unlimited opportunity to substantially improve on your operations and profitability.

Applications

- Treatment and washing of various sands; natural, crushed, glass, foundry etc,

- All types of quarry waste including cohesive silty materials,

- Crushing of scalpings to produce manufactured sand,

- Tailings with a considerable presence of fine particles and with a variable composition of minerals, which could limit the direct application of those wastes,

- Recycling quarry waste will also lead to preventation of potential impacts, such as;

Water : Run-off from quarry waste stockpiles can cause erosion and contaminate local watercourses,

Dust : Large quarry waste stockpiles can be a source of airborne dust,

Why MEKA Quarry Waste Recycling?

- MEKA offers innovative solutions while respecting the environment and meeting the requirements of its customers, MEKA has proven its commitment to sustainable construction by recycling quarry waste for many years into recycled aggregates.

- Detailed analysis of your feed material is undertaken to establish the volume of commercial sand and aggregate material that can be recovered,

- Using state of the art washing, crushing and screening machinery, we are able to transform these by-products into valuable products helping to reduce stockpiling on site and prolong the life of mineral extraction sites.

MEKA Quarry Waste Recycling Advantages

• TRANSFORM WASTE INTO VALUABLE RESOURCES

Quarry waste recycling helps to support a circular economy by recovering aggregate material destined for the landfill and processing it for reuse in the construction industry. MEKA supports these efforts with complete packaged solutions for feeding, crushing, screening, washing, classifying, dewatering in quarry waste recycling applications.

• FEEDING

MEKA feeders are designed specifically for the application’s material size, material characteristics (wet, sticky) and desired throughput, and then programmed to feed the waste at a set rate to match the capacity of a crusher. Some are designed with the means to scalp the feed to screen out the undersized product.

Types of feeders for quarry waste applications;

- Apron Feeders,

- Wobbler Feeders,

- Vibrating Grizzly Feeders,

- Pan Feeders with Grizzly Scalper,

CRUSHING

MEKA offers a wide range of primary, secondary and tertiary crushers for size reduction through compression, impact, and attrition or shear forces. MEKA’s in-house laboratory offers material testing to provide you with a crusher that will fit your requirements.

Types of crushers for quarry waste applications;

- Jaw crushers (primary and secondary)

- Impact crushers (HSI, VSI and hammermill)

- Cone crushers,

• SCREENING

MEKA offers both stationary and portable screening equipment designed to separate material, reduce fines generation, remove refuse material and minimise crusher size.

Types of screens for quarry waste applications;

- Inclined and horizontal screens,

- Grizzly screens,

- Fine material screens,

• WASHING, CLASSIFYING AND DEWATERING

Once the aggregate material recovered from quarry waste streams has been properly sized and sorted, it may need to undergo additional processing before it can be used for certain construction projects. The wet processing part of the quarry waste recycling operation includes washing and scrubbing away deleterious material from the sound aggregate.It can also include classifying and dewatering the sand fraction.

MEKA has vast knowledge and experience in designing wet processing systems, with plants consisting of various configurations of MEKA’s reliable equipment operating around the globe.

Because requirements vary from site to site, MEKA’s extensive range of wet processing equipment ensures that each customer has the best solution for their recycling application and will get the highest return on investment from their equipment purchase.

Types of wet processing equipment for quarry waste applications;

- Washing screens,

- Dewatering screens,

- Coarse material washers,

- Fine material washers,

- Blade mills,

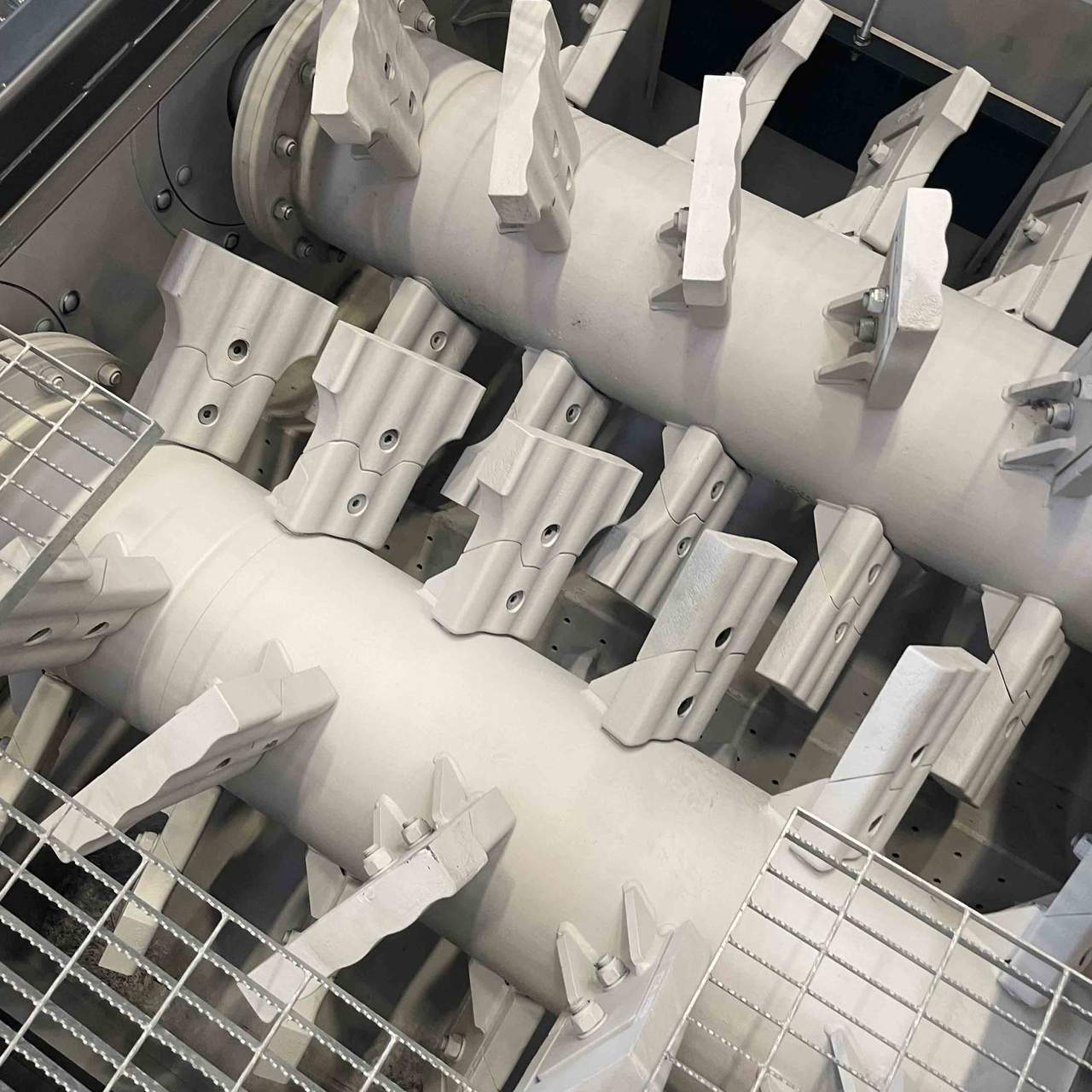

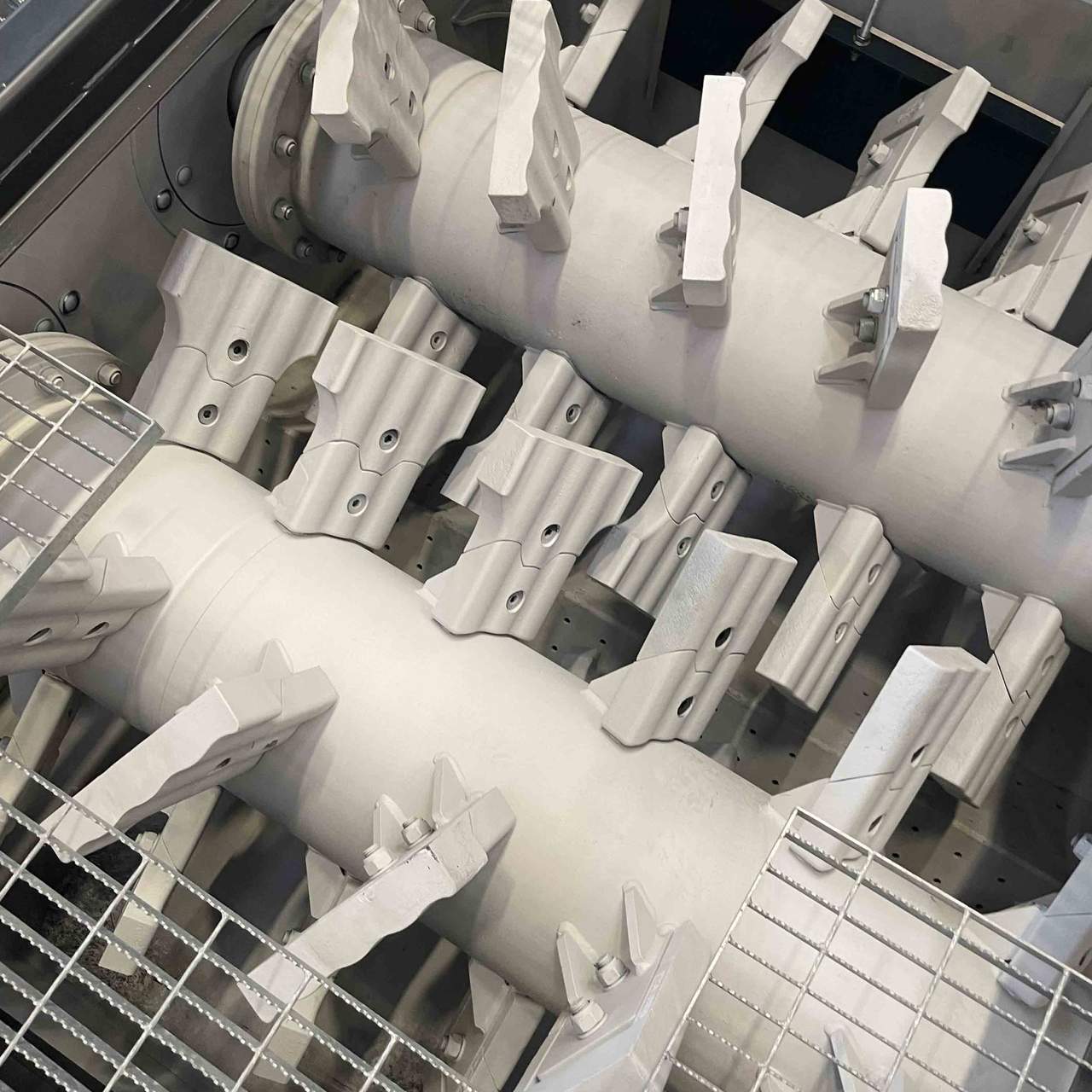

- Log washers,

- Scrubbers and attrition cells,

- Compact sand plants

-

Downloadable Files

Quarry Waste Recycling Technical Specifications

What are Quarry Waste Recycling?

Explore Our Projects Worldwide

Stay in Touch with Us

Subscribe to our newsletter now to stay informed about our new projects and products and be the first to learn the latest news from MEKA!