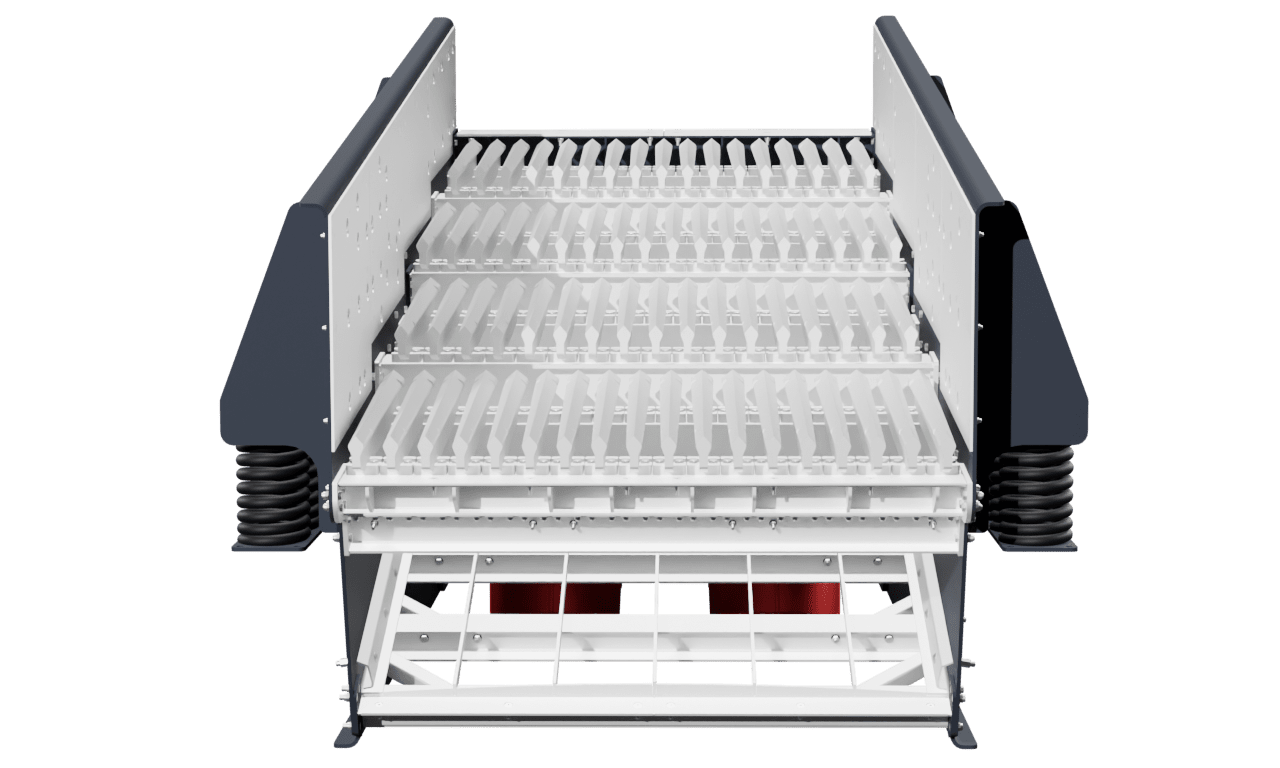

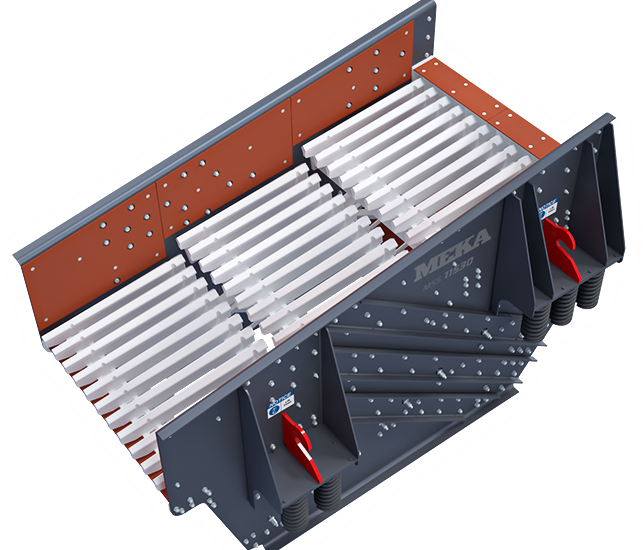

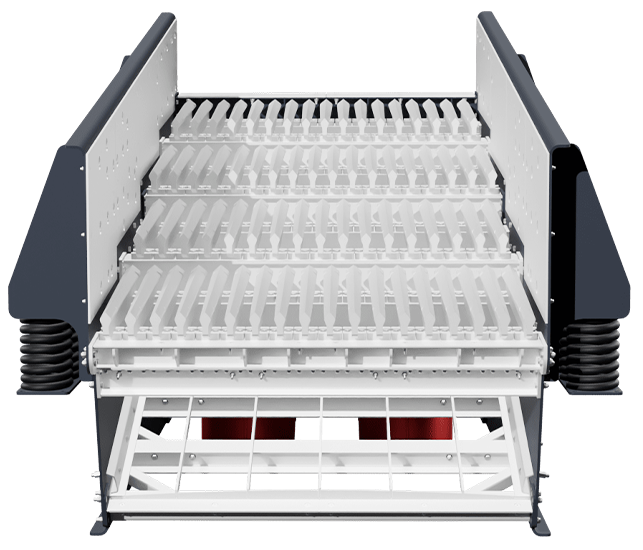

Scalper or scalping screens are primary type heavy duty equipment with linear motion.

Scalping Screen

Applications

Scalping screens MSS are often utilized when excessive clay or an abundance of fines are present, making them capable of efficient scalping in the most difficult applications. Typical feed material is blasted rock, ripped rock or gravel with high fines content, often containing difficult wet natural fines or clay. The Scalping screens MSS are able to maximize the efficiency of the primary plant across wide variations in application.

Why MEKA Scalping Screen?

- Maximum efficiency

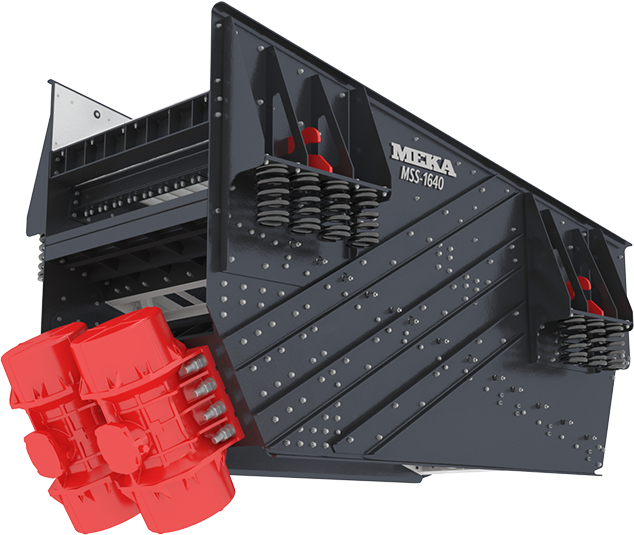

High G force resulting in very high scalping efficiency for better feed to the crusher

- Speed and stroke is adjustable

Long stroke capability: better scalping efficiency (when feed material contains high ratio of flaky material)

Shape of Scalping grizzlies result in: reduced blinding when feed is sticky and contains fines (increased capacity)

MEKA Scalping Screen Advantages

-

MEKA Scalping Screen Download Catalogue

Scalping Screen Technical Specifications

MSS 1030 |

MSS 1230 |

MSS 1440 |

MSS 1530 |

MSS 1640 |

MSS 1940 |

|

| WidthxLength (mm) WidthxLength (feet) | 1000x3000 3⅟4'x10' | 1200x3000 4'x10' | 1400x4000 4⅟2'x13' | 1500x3000 5'x10' | 1600x4000 5⅟4'x13' | 1900x4000 6⅟4'x13' |

| Number of Decks Number of Decks | 2 2 | 2 2 | 2 2 | 2 2 | 2 2 | 2 2 |

| Power @50Hz (kW) Power @50Hz (HP) | 2x6.1 2x8.3 | 2x7.5 2x10 | 2x12 2x19.4 | 2x10.1 2x13.5 | 2x13.9 2x18.6 | 2x22.6 2x30.3 |

| Power @60Hz (kW) Power @60Hz (HP) | 2x7.5 2x10 | 2x8 2x10.7 | 2x11 2x14.7 | 2x10.6 2x14.2 | 2x16.5 2x22.1 | 2x16.5 2x22.1 |

| Length of Grizzly (mm) Length of Grizzly (inch) | 1000 39.4 | 1000 39.4 | 1000 39.4 | 1000 39.4 | 1000 39.4 | 1000 39.4 |

| *Weight (kg) *Weight (lbs) | 4520 9965 | 5470 12059 | 9000 19842 | 6750 14881 | 9650 21275 | 12500 27558 |

* Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes.

What is Scalping Screen?

Scalping screen, also known as scalper are separation equipment consisting of grizzly deck and an optional deck with wire mesh used for scalping and screening after the apron, pan or push feeder in the primary stage. A scalping screen separate oversized material from the finer material in the feed.