Hammer Crusher

Applications

Why MEKA Hammer Crusher?

High throughput capacity due to large grinding grate respectively screening area,

Low space requirements due to extremely low construction height,

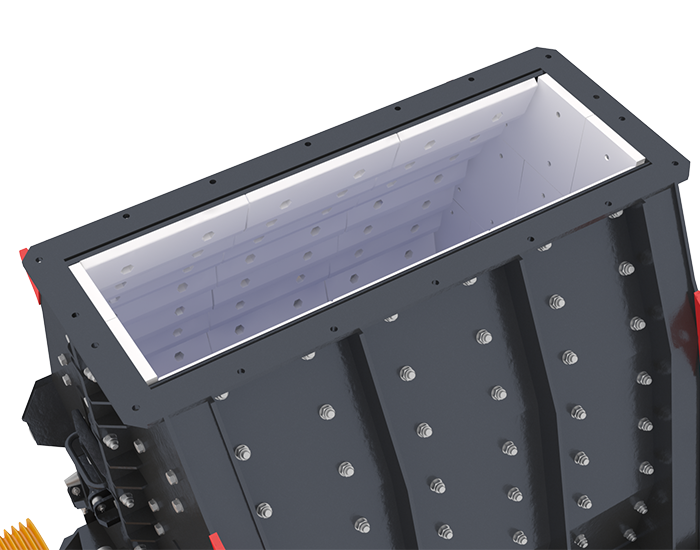

Large intake cross-section for bulky feed material,

High and constant capacity,

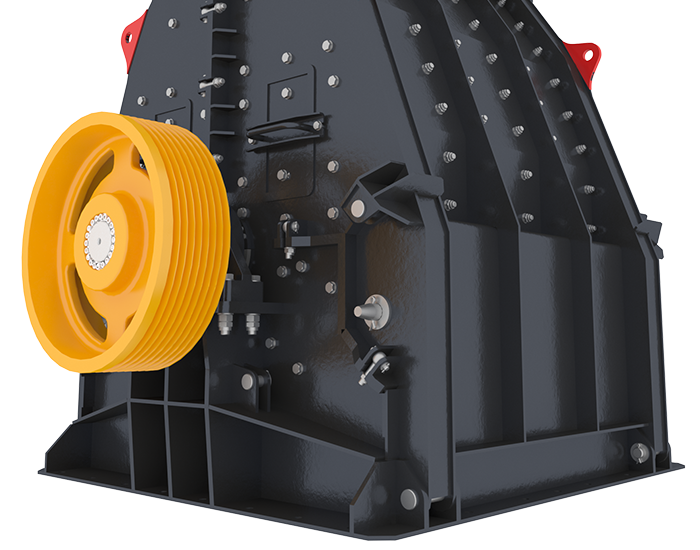

Easy replacement of wear and spare parts through hydraulic opening device,

Broad range of applications,

High reduction ratio.

MEKA Hammer Crusher Advantages

-

MEKA Hammer Crusher Download Catalogue

Hammer Crusher Technical Specifications

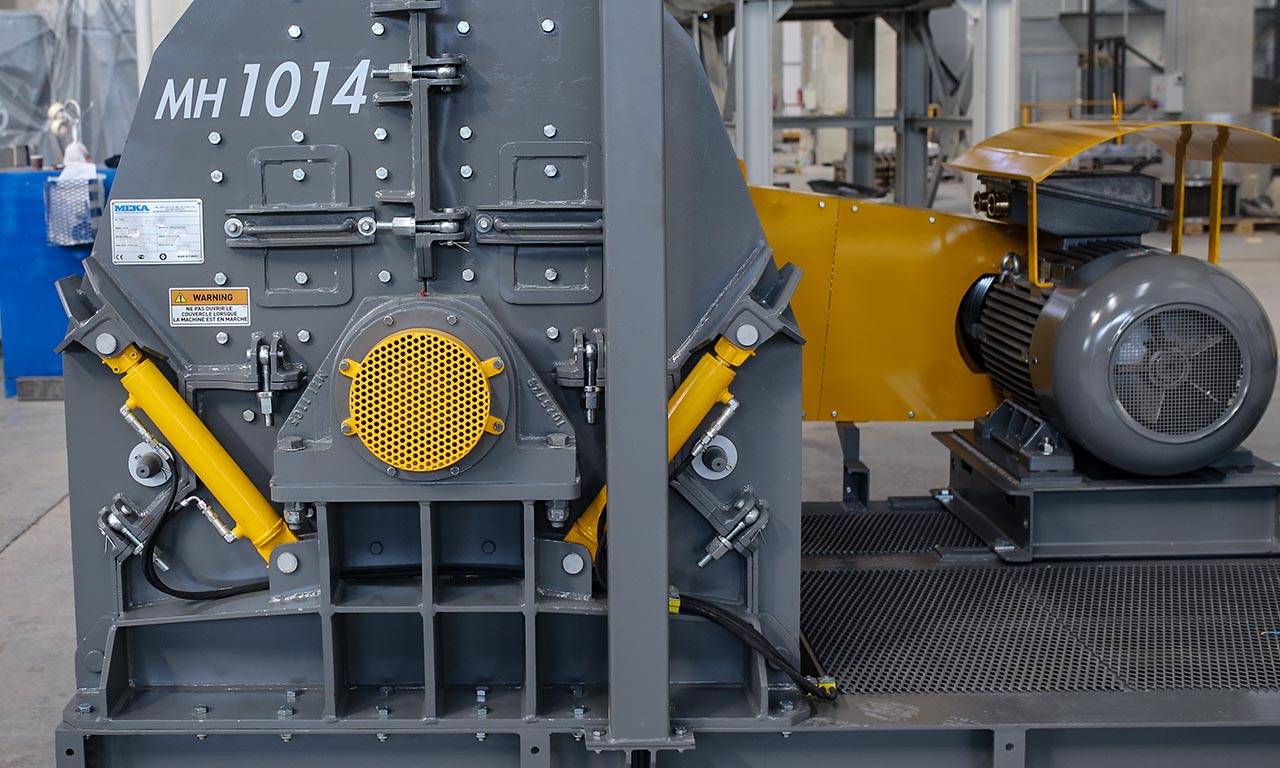

MHC 1014 |

MHC 1214 |

|

| Rotor Diameter (mm) Rotor Diameter (inch) | 1000 39" | 1200 47" |

| Rotor Width (mm) Rotor Width (inch) | 1400 55" | 1400 55" |

| Feed Opening (mm) Feed Opening (inch) | 1420x250 40"x9" | 1420x410 56"x16" |

| *Capacity (mtph) *Capacity (stph) | 40-100 54-110 | 50-150 55-165 |

| Power (kW) Power (HP) | 90-132 125-170 | 132-160 170-220 |

| **Weight (kg) **Weight (lbs) | 7940 17505 | 9690 21360 |

*For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit design.

***Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes

What is Hammer Crusher?

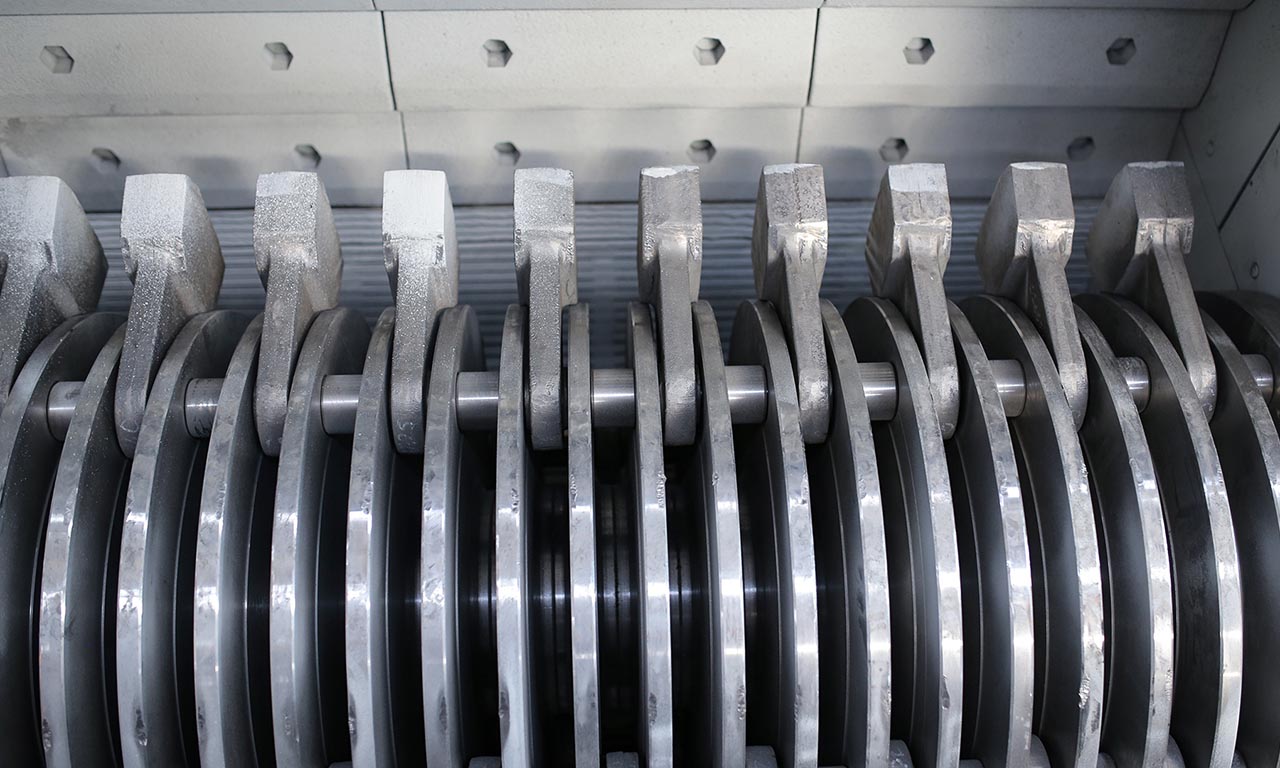

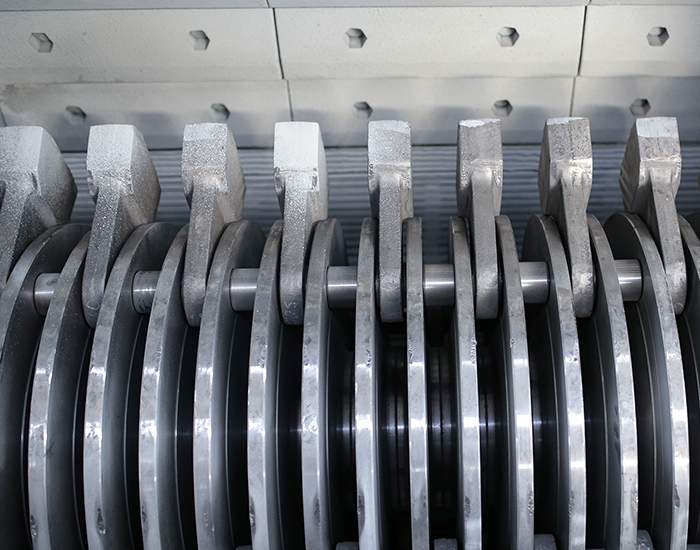

Hammer crusher consists of a body lined with abrasion resistant liners and a rotor with a series of hammers. The crusher discharge section has grid that determine the final product size. The hammers are free to swing on pivots as the rotor rotates.

*Hammer crushers are high efficient crushers in size reduction with high reduction ratio .

*Possibility to control the end product size by changing the crusher's grid gap opening.

*Hammer crushers are relatively simple to operate and maintenance.