The Environmental Impacts of Concrete

ENVIRONMENTAL IMPACTS OF CONCRETE

Concrete is the most common construction material used in building industry. On average approximately 1 ton of concrete is produced each year for every human being in the world. Therefore concrete is one of the World’s most significant manufactured materials. Because of its abundance in the world market, understanding the environmental implications of concrete and cement manufacturing are becoming increasingly important.

Building production activities have a negative impact on the environmental balances by consuming natural resources and generating waste. Environmental impacts at various stages of production determine the overall environmental impact of the structure. Although the structure production process in the building life cycle is shorter than other processes, the negativities in this process significantly increase the total environmental impact of the structures. It is important that every stage of production carries ecological characteristics in order to have ecologically / sustainably sensitive structures.

Looking at the use of materials and the production of waste in general the construction sector is by far the biggest industrial sector all over the world. For this simple reason serious analysis of the potential environmental and ecological effects of construction activities and structures is indispensable.

Sustainable development has become a major concern in the last decade worldwide. At the UN conference in Rio de Janeiro in 1992 178 nations signed the 'Rio Declaration' and thus accepted the basic principle of sustainable development. One important aspect of sustainability is related to environment, namely to reduce or to avoid the pollution of air, soil and water with substances dangerous to mankind, fauna and flora now and in the future. Another important aspect is to save non-renewable natural resources.

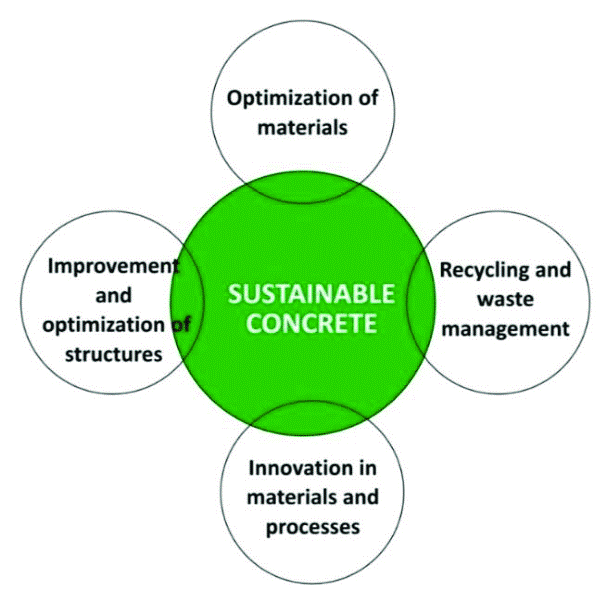

Concrete is being recognized for its strong environmental benefits in support of creative and effective sustainable development. In response to growing environmental and economic forces, regulatories, engineers, developers and owners are seeking efficient, innovative concrete solutions that conserve non-renewable resources. When considering the lifetime environmental impact of a building material -extraction, production, construction, operation, demolition and recycling concrete is the most advantageous choice to meet these goals. Global demands for regulating concrete production waste arise from the growth of these environmental and economic issues. Various efforts have been conducted by researchers to arrive at some alternatives that are able to significantly reduce high energy consumed and environmental impacts during fabrication process of cement. Therefore, the concept of "green concrete" as an environmentally friendly alternative to conventional concrete has been emerging

Geopolymer concrete, or green concrete, is part of a movement to create construction materials that have a reduced impact on the environment. It is made from a combination of an inorganic polymer and between 25% and 100% industrial waste.

Benefits of using green concrete

- Lasts Longer

- Uses Industrial Waste

- Reduces Energy Consumption

- Reduces Carbon Dioxide Emissions

Lasts Longer:

Green gains strength faster and has a lower rate of shrinkage than made only from Portland Cement. Structures built using green have a better chance of surviving a fire, as it can withstand temperatures of up to 2400°F . It also has a greater resistance to corrosion, which is important with the effect pollution has had on the environment. Acid rain greatly reduces the longevity of traditional building materials. All of those factors add up to a building that will last much longer than one made with ordinary

Uses Industrial Waste

Instead of a 100% Portland cement mixture, green concrete uses between 25% and 100% fly ash. Fly ash is a byproduct of coal combustion. It is gathered from the chimneys of industrial plants that use coal as a power source. There are copious amounts of this industrial waste product. Hundreds of thousands of acres of land are used to dispose of fly ash. Green concrete provides a way to use fly ash and save many acres of land.

Reduces Energy Consumption

If you use less Portland cement and more fly ash when mixing , then you will use less energy. The materials that are used in Portland cement require huge amounts of coal or natural gas to heat. Fly ash already exists as a byproduct of another industrial process, so you are not expending much more energy to use it to create green . Another way that green reduces energy consumption is that a building constructed from it is more resistant to temperature changes, thus saving heating and cooling costs.

Reduces Carbon Dioxide Emissions

Among the main ingredients in ordinary cement are pulverized limestone, clay, and sand which are heated to a high temperature. This process is responsible for between 5 and 8% of all Carbon Dioxide emissions worldwide. The manufacturing of green releases up to 80% fewer Carbon Dioxide emissions.

Disadvantages

- By using stainless steel, cost of reinforcement increases.

- Structures constructed with green concrete have comparatively less life than structures with conventional concrete.

- Split tension of green concrete is less than that of conventional concrete.

References

1. Şanal İ.“ Significance of concrete production in terms of carbondioxide emissions: social and environmental impacts”, Politeknik Dergisi, 21(2): 369-378, (2018).

2. Betonarme yapım sistemlerinin ekolojik açıdan değerlendirilmesi -Doç. Dr. Tülay Esin GYTE, Mimarlık Fakültesi, Mimarlık Bölümü, Çayırova - Gebze - Kocaeli , Yrd. Doç. Dr. Nilay Coşkun GYTE, Mimarlık Fakültesi, Mimarlık Bölümü Çayırova - Gebze - KocaeliCOŞGUN2

3. Eederation internationale du beton the international federation for structural created from the merger of CEB and FIP Environmental effects of State-of-art report prepared by Task Group 3.4 March 2003

4. The Constructor- Green -Gopal Mishra Civil Engineer

5. Do ityourself-Environmental Benefits to using Green Concrete