-

PRODUCTS

-

Ready Mix Concrete Plants

- READY MIX CONCRETE PLANTS HOME

- MOBILE CONCRETE BATCHING PLANTS

- COMPACT CONCRETE BATCHING PLANTS

-

STATIONARY CONCRETE BATCHING PLANTS

- STATIONARY CONCRETE BATCHING PLANTS HOME

- K60 STATIONARY CONCRETE BATCHING PLANT

- K90 STATIONARY CONCRETE BATCHING PLANT

- K120 STATIONARY CONCRETE BATCHING PLANT

- K135 STATIONARY CONCRETE BATCHING PLANT

- K145 STATIONARY CONCRETE BATCHING PLANT

- K160 STATIONARY CONCRETE BATCHING PLANT

- K200 STATIONARY CONCRETE BATCHING PLANT

- DRY BATCH CONCRETE BATCHING PLANTS

- PRECAST CONCRETE BATCHING PLANT

- RCC CONCRETE BATCHING PLANTS

- Concrete Mixers

- Concrete Plants Components

-

After Sales Services and Spare Part

-

Concrete Batching Plant Automation System

Crushing & Screening Plants, Mining, Robust, Reliable, Robust, Reliable, Robust for Ready-Mixed Concrete Production and Recycling Industries.... -

Ready Mix Concrete Plants

- CORPORATE

- NEWS

- BLOG

- CASESTUDIES

- SERVICE

Vibrating Screen Efficiency Calculations

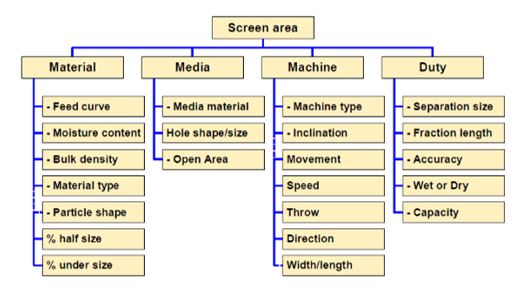

For the efficient use of number of conditions need to be met, starting from the selection of a suitable . Many factors related to the material, such as type, humidity and size distribution should be considered in the selection of the right These factors are presented in Table 1. Choosing the correct type and the right dimension is something that requires expertise. MEKA’s expert engineers will boost your profitability by choosing a that is right for you.

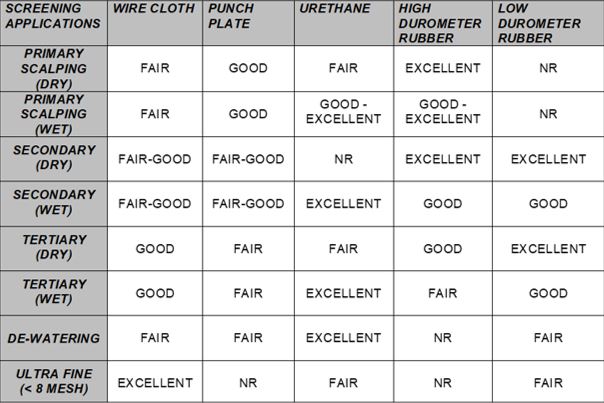

Another important factor affecting efficiency is the choice of the baffle, which can be made of such materials as wire and polyurethane. The baffle should be resistant to vibration, should have sufficient open space and should be resistant to wear. The relationship between the type of and the baffle is shown in Table 2.

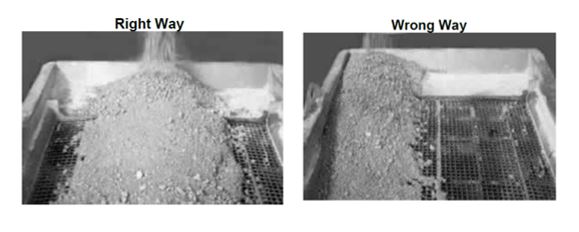

The efficient operation of a s related closely to how the s fed. The belt that feeds the should provide feeding in parallel with the flow direction of the material, and in a manner that brings the materials to the center of the loading vessel. Picture 1 shows proper feeding and improper feeding.

Picture 1. On the left is the proper way of feeding the , while on the right is the improper way of feeding the .

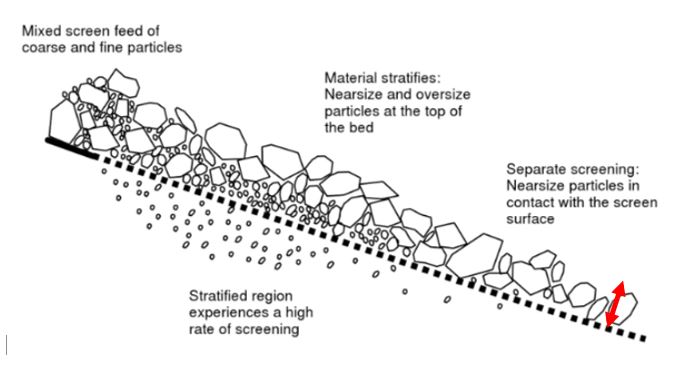

Another important factor in efficient is the layer height (or bed). The layer height refers to the height formed by the layer on the wire surface at the point at which the material is loaded. The ideal height is four times the aperture.

The capacity and efficiency of are usually inversely proportional. The usual target is a efficiency of 95%. An efficiency of 99% will equate to a significant loss of capacity.

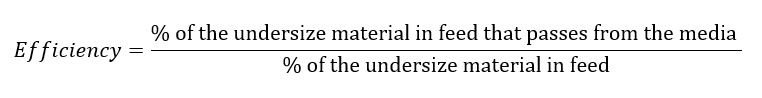

Efficiency is the ratio of undersize material in the feed that actually passes from the media to the undersize material that should pass from the media. This ratio is desired to be 100%, however this is not possible due to the factors affecting the process.

However, acceptable efficiency ranges have been determined by producers and quarry managers to ensure an optimum process. According to the determined ranges,efficiency should be in the range of 90%-95% with respect to the above formula.

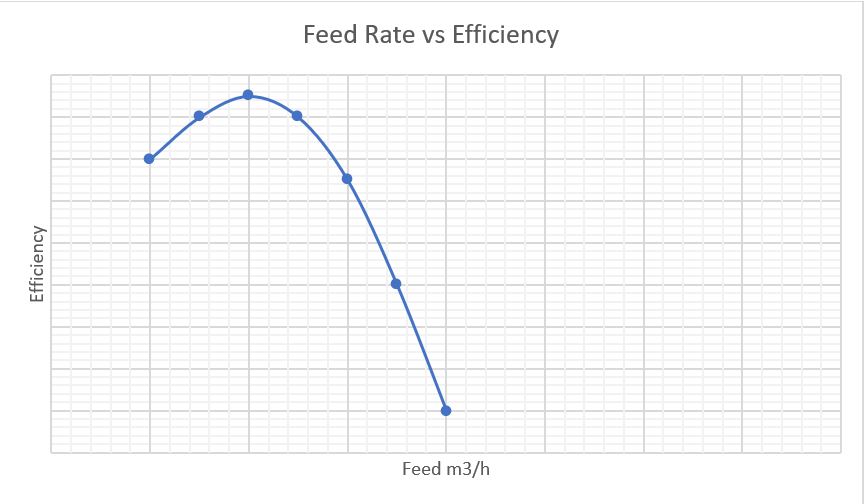

Feed rate is the main parameter dictating efficiency. If the flow rate is below the capacity of the media, the runs idle so no s carried out. On the other hand, if the flow rate is above the capacity of the media, runs under the overflow rate, and in this case no is made due to the high material depth on the media. Accordingly, selection has to be made with due attention paid to the flowrate to obtain maximum efficiency.

Efficiency is affected by the factors listed below:

- Wear, abrasion and tearing in then baffle.

- Feeding too much or too little material onto

- Large changes in grade.

- Humidity level of the material.

- Efficiency of the machine used prior to.