A fiber dosing system ensures that steel or synthetic fibers are added to the concrete mix in the desired amount and in a homogeneous manner. This increases the crack resistance of the concrete and results in a more durable structure. Compared to manual dosing, it operates with higher precision, preventing material waste and speeding up processes.

Classification according to volume fraction

Low volume fraction (< 1%)

Are used to reduce shrinkage cracking. These are used in slabs and pavements that have large exposed surface leading to high shrinkage crack.

Moderate volume fraction (between 1 and 2%) :

The presence of f at this volume fraction increase the modulus of rupture, fracture toughness, and impact resistance.

High volume fraction (greater than 2) :

The used at this level lead to strain hardening of the composites

Fiber Feeding-Dosing Systems

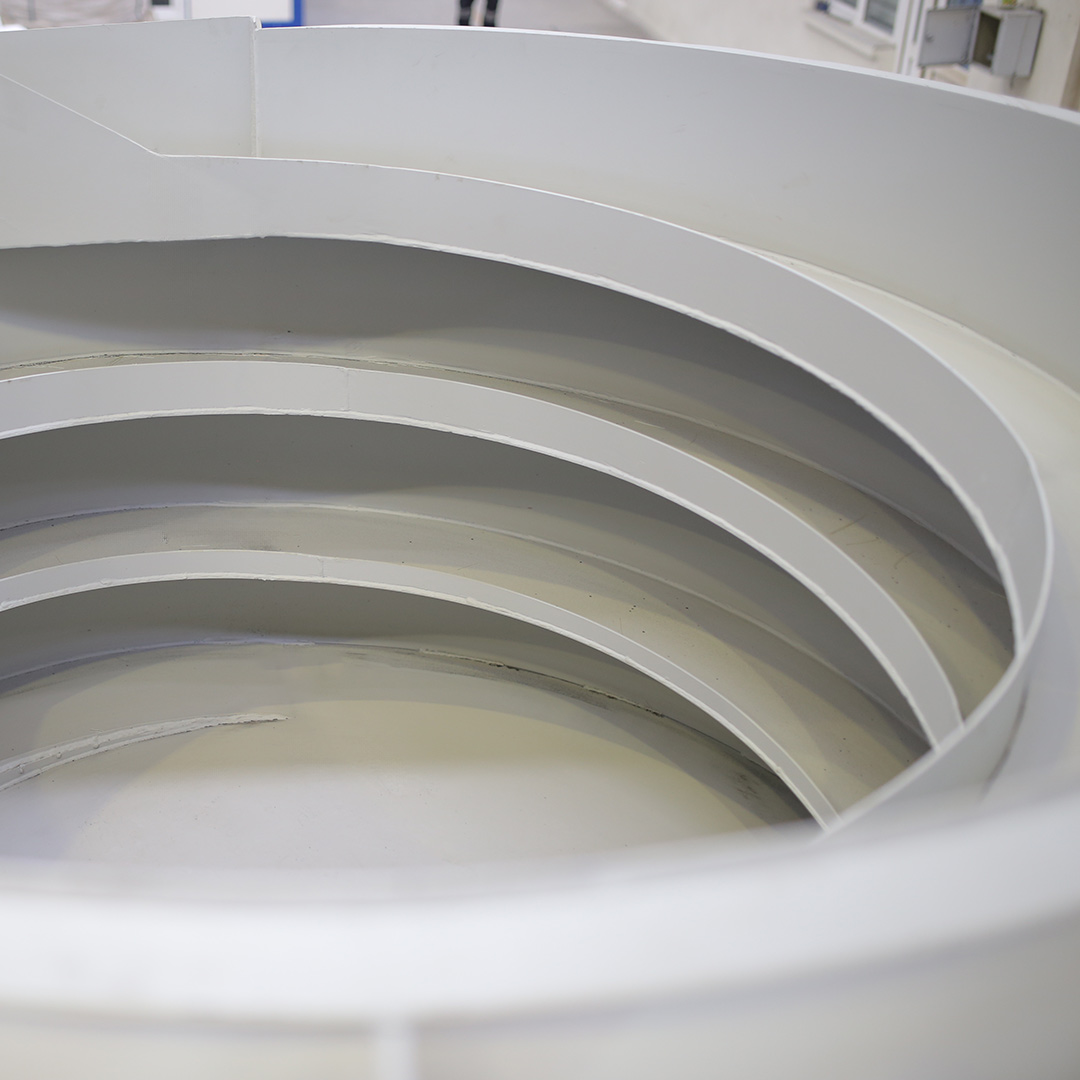

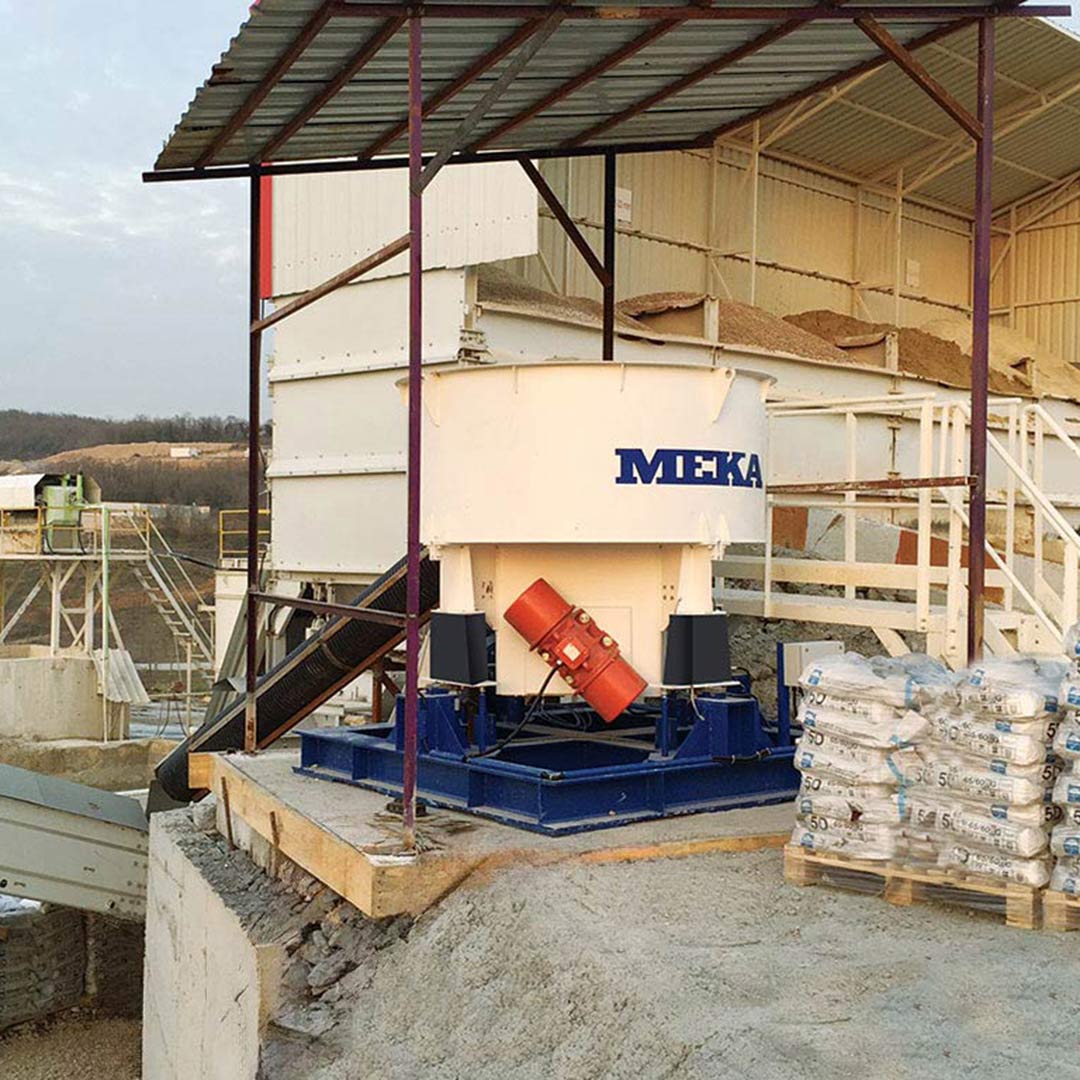

When are used in small amounts it is common to order in small pre-weighed packs and let the directly into the plant mixer or mixer truck without need for special feeding system. But when it comes to high capacity mass production with high precision and homogeneity this is where MEKA shows its best.MEKA Dosing equipment includes highly accurate steel/hard plastic and soft dosing systems with a range of dosing capacities shown in the table to suit the individual needs of our customers. MEKA Feeding Systems are with integrated conveyor and with a storage available on request as well as additional equipment custom-made for the requirements of our customers.weighing and feeding process can be integrated into the automation of the concrete plant to ensure full control over mixing quality and homogeneity. All dosing-feeding equipment is produced in accordance with CE and EMC directives.

Fiber Feeding-Dosing Systems Gallery

Fiber Feeding-Dosing Systems Optional Features

Fiber dosing systems are used to automatically measure and add steel or synthetic fibers to concrete mixtures in precise proportions. These systems enhance the durability, crack resistance, and structural integrity of concrete.

Fibers are commonly used in projects that require high durability, such as industrial floors, tunnels, bridges, precast structural elements, and screed applications. Compared to manual dosing, automated dosing systems provide a more accurate and efficient process, minimizing errors and saving time.

Fiber dosing systems can dose various types of concrete reinforcement fibers.

These include:

Steel Fibers → Improve the tensile strength and impact resistance of concrete.

Polypropylene (PP) Fibers → Prevent plastic shrinkage cracks and enhance flexibility.

Glass Fibers → Used in lightweight structural elements and special concrete types.

Carbon or Hybrid Fibers → Preferred for high-performance projects.

Fiber dosing systems typically operate in either semi-automatic or fully automatic modes. In fully automatic systems, the fiber amount is pre-programmed and precisely measured by the system before being added to the mix. This minimizes human error and ensures more consistent results.

The key advantages of fiber dosing systems include:

-Accurate Proportioning: Prevents errors by measuring more precisely than manual dosing.

-Time Efficiency: Eliminates the need for manual addition, speeding up the process.

-Homogeneous Mixing: Ensures fibers are evenly distributed within the concrete.

-Cost Savings: Reduces material waste, making it more economical.

-Improved Concrete Quality: Produces more crack-resistant and durable concrete.

Fiber dosing systems are used in various projects requiring durability:

-Industrial Floors → Provides durable concrete surfaces against heavy loads.

-Tunnels and Bridges → Enhances structural integrity by preventing cracks.

-Precast Concrete Production → Improves the strength and durability of prefabricated elements.

-Screed and Floor Coatings → Prevents shrinkage cracks.