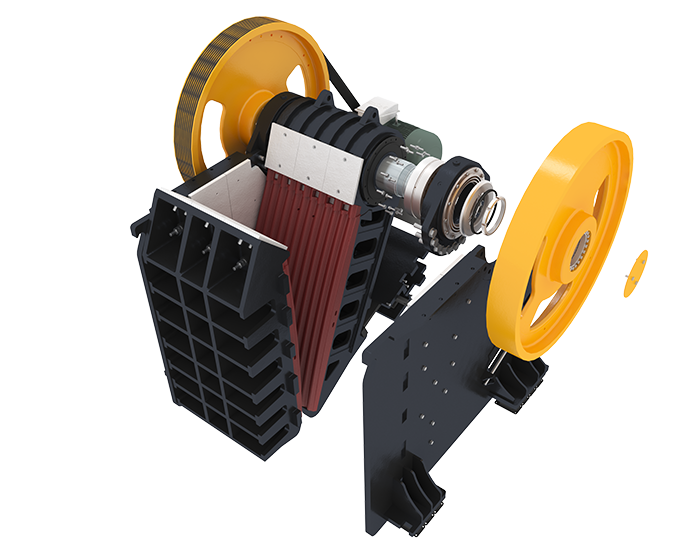

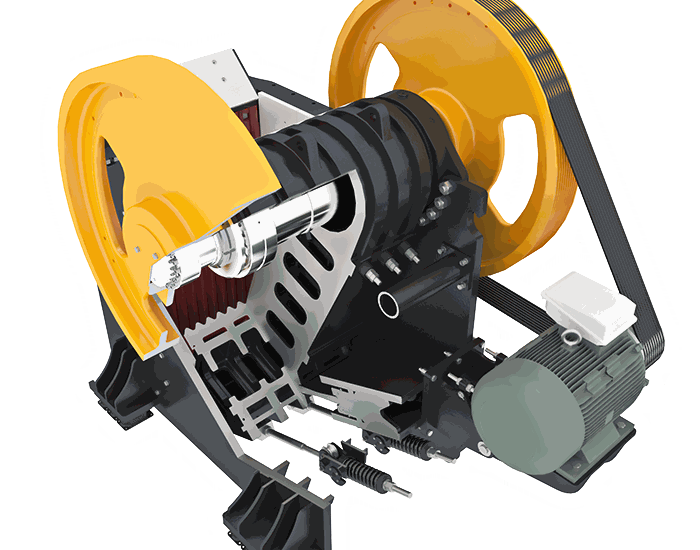

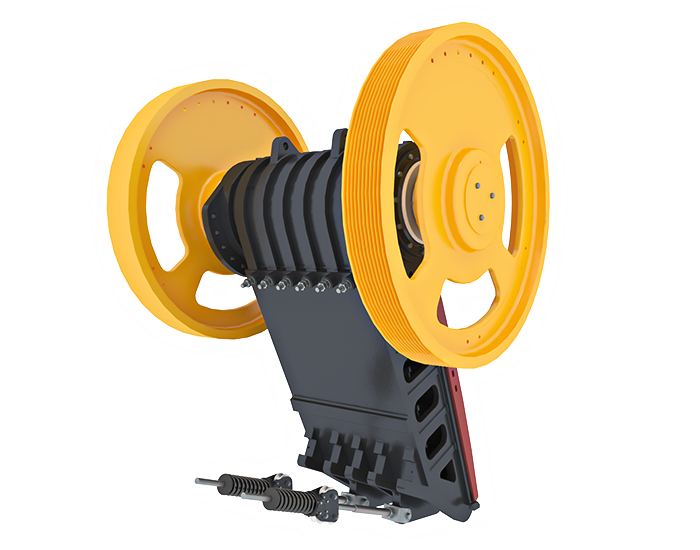

Two different designs of jaw crushers are also produced, being single or double toggle depending on the movement system of the jaw. Single toggle jaw crushers are the most common type, double toggle jaw crushers are for crushing of extremely hard materials.

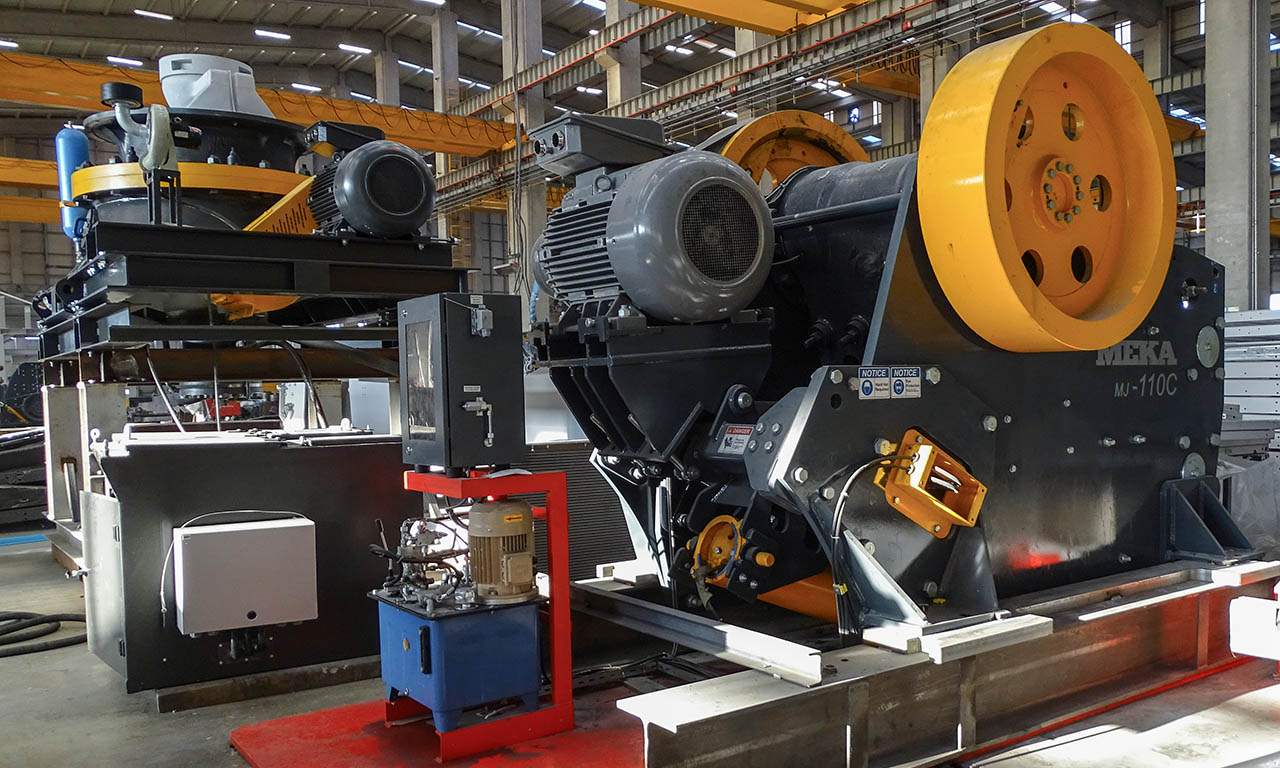

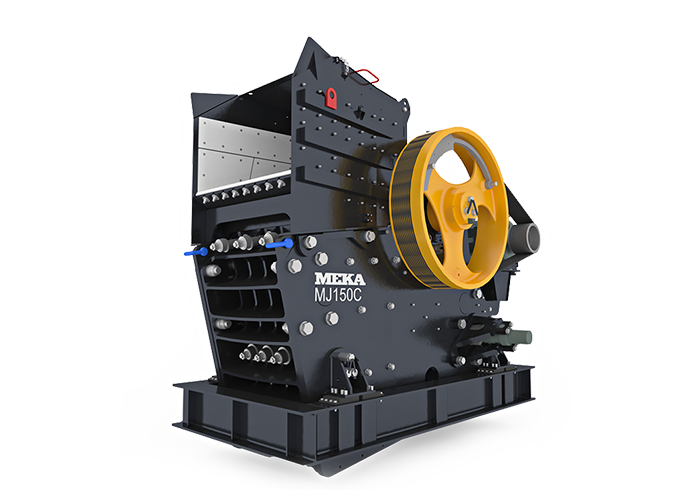

Jaw Crusher

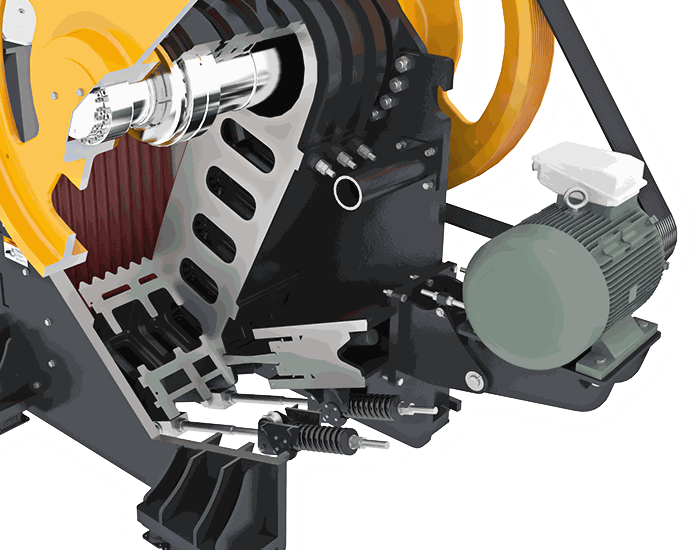

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their low-cost operation and easy maintenance. There are also primary and secondary types of these crushers.

Applications

Primary and secondary crushing applications for quarrying, mining, recycling and industrial minerals.

Toughest feed materials,

Stationary, underground and mobile crushing applications.

Why MEKA Jaw Crusher?

- High reduction,

- Low jaw plate wear,

- Large feed acceptance capability,

- Optimized nip angle ensures that the material progresses smoothly down through the crushing chamber to enable high reduction, productivity and superb utilization of jaw plates.

MEKA Jaw Crusher Advantages

-

MEKA Jaw Crusher Download Catalogue

Jaw Crusher Technical Specifications

MJ 60 |

MJ 65 |

MJ 70 |

MJ 90 |

MJ 110 |

MJ 130 |

MJ 110C |

MJ 120C |

MJ 150C |

MJS 90 |

MJS 110 |

|

| Feed Opening (mm) Feed Opening (inch) | 610x380 24x15 | 650x500 25,6x19,6 | 700x400 27,6x15,7 | 900x650 35,4x25,6 | 1100x850 43,3x33,5 | 1300x1000 51,2x39,4 | 1070x770 42,1x30,3 | 1200x870 34x47 | 1400x1200 55x47 | 900x200 35,4x8 | 1100x350 43,3x13,8 |

| CSS (Min - Max Setting) (mm) CSS (Min - Max Setting) (inch) | 40-150 1,57-5,9 | 40-150 1,57-5,9 | 30-100 1,18-3,93 | 60-150 2,4-5,9 | 100-200 3,9-7,9 | 125-250 4,9-9,8 | 75-210 2,9-8,2 | 70-175 2,75-6,9 | 125-250 4,9-9,9 | 25-75 1-2,9 | 25-100 1-3,9 |

| *Capacity (mtph) *Capacity (stph) | 20-80 22-88 | 25-100 27-110 | 25-100 27-121 | 50-200 55-220 | 100-300 110-330 | 275-600 303-661 | 135-340 148-374 | 175-595 192-655 | 340-970 374-1069 | 10-80 11-88 | 40-200 44-220 |

| Power (kW) Power (HP) | 30 40 | 45 60 | 45 60 | 75 100 | 132 180 | 160 220 | 110 150 | 160 200 | 200 300 | 30 40 | 75 100 |

| **Weight (kg) **Weight (lbs) | 6000 13228 | 7000 15432 | 4200 9259 | 11400 25132 | 33000 72752 | 43000 94798 | 19000 41887 | 27990 61710 | 55400 122136 | 6000 13228 | 11000 24250 |

* For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit design.

** Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes

What is Jaw Crusher?

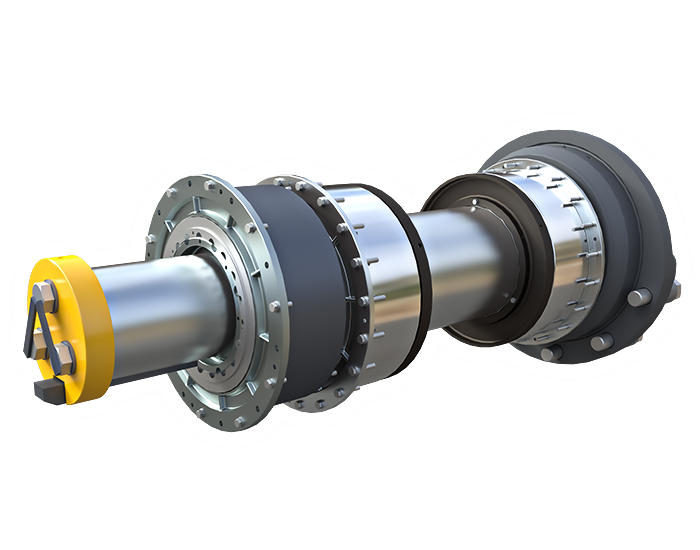

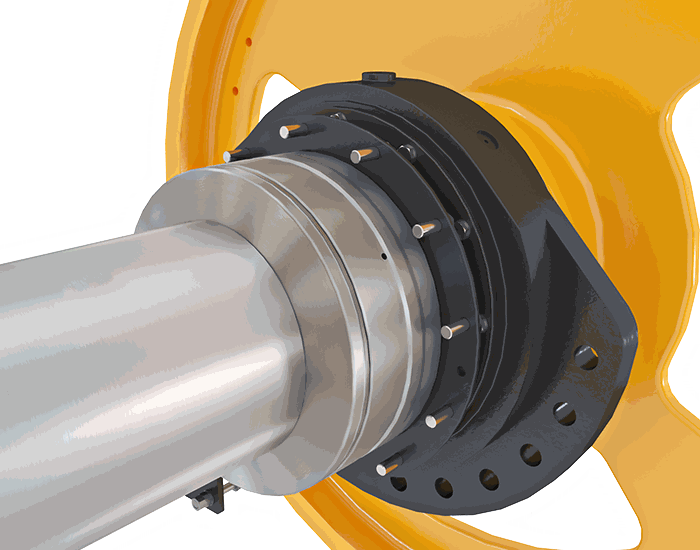

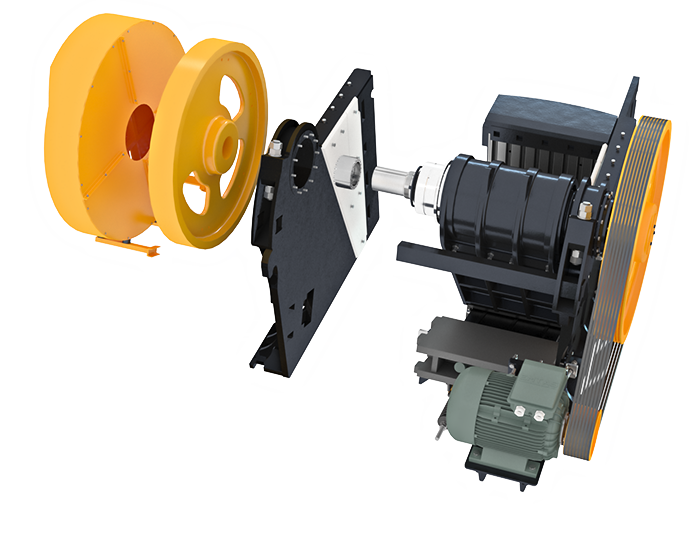

Jaw crushers comprise one fixed and one moving jaw. Material is crushed between the movable jaw and the fixed jaw through the application of compressive force produced by the elliptical motion of the movable jaw. The movable jaw, which is supported from the top by an eccentric shaft, is connected to the tension rod and built-in an angled toggle plate that absorbs the cyclic loads in the bottom section.

· The use of jaw crushers in underground applications is convenient and common, as they can be produced with few parts, and are easy to carry, assemble and maintain.

· There are no capacity problems, as the desired capacity can be achieved by using more than one crusher in parallel when necessary.

· They are easy to maintain and affordable.

· The replacement of worn jaws is not time-consuming.

Jaw crushers are used as the primary crushers in the first stage of the crushing process and are preferred when breaking large rocks is the priority rather than achieving high capacity.

Jaw crushers can be used as first-stage crushers in small- and medium-sized plants, as well when secondary crushing is necessary.

The stroke of the jaw generally varies between 20 and 40 mm, That said, the closed side setting at the discharge is as important as the feed opening of the jaw crusher. Closed side setting can be adjusted within certain limits.