Generally installed under surge bins for feed regulation at the secondary or tertiary crushing stages and are also used in tunnels under open stockpiles for regular feeding to conveyor belts inside the tunnel.

Vibrating Feeder

Vibrating Feeder

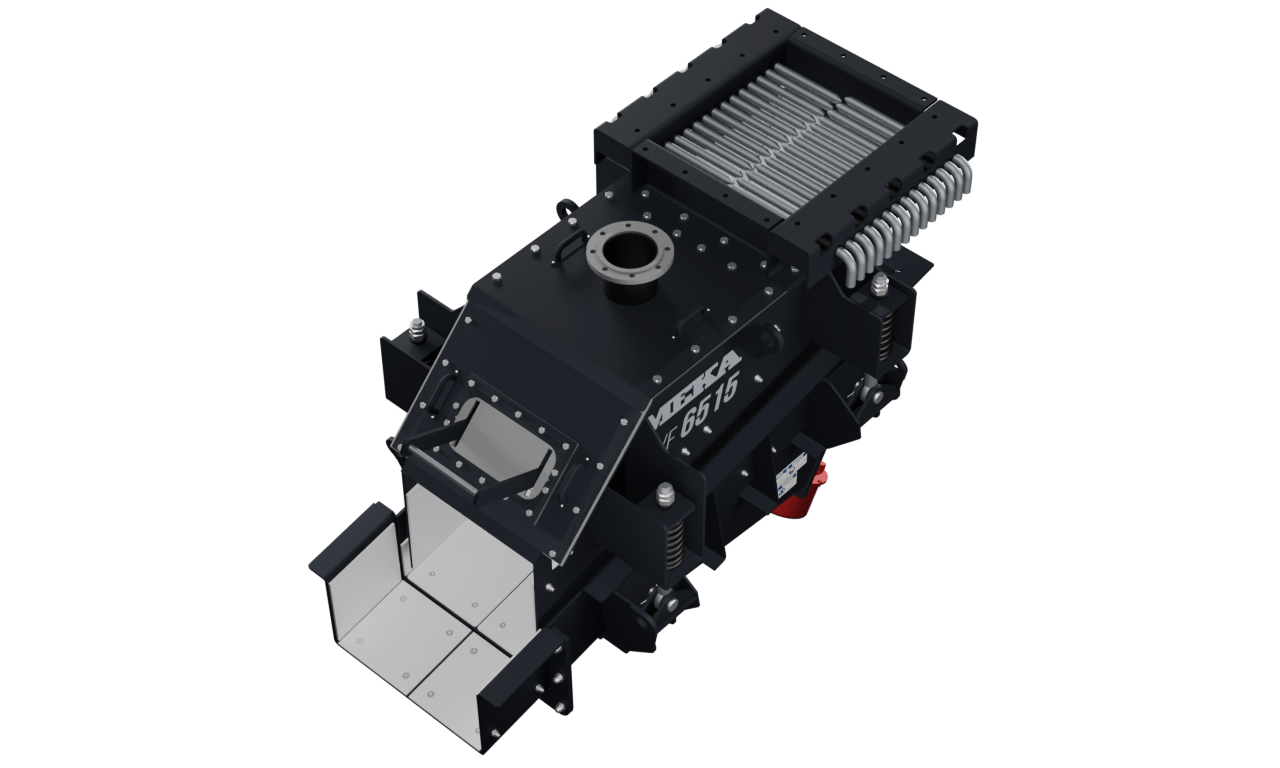

The design and wide size range of MEKA vibrating feeders is adapted to make proper access around crushers possible and decrease the total cost of the installation. The versatile design can be mounted on support springs or suspended on coil springs, depending on the location and application.

-

MEKA Vibrating Feeder Download Catalogue

Applications

MEKA MVF Vibrating Feeders are designed for high capacity feeding especially for secondary and tertiary duties. MVF feeders all work on the same principle, that being the extraction of materials from under crushers, bins, hoppers etc, or fed by a conveyor with a regulated flow to promote a steady supply to maximise production in the processing plant.

Vibrating Feeder Technical Specifications

MVF 6515 |

MVF 8517 |

MVF 1020 |

MVF 1220 |

MVF 1520 |

MVF 1020C |

MVF 1320C |

MVF 1520C |

|

| Width x Length (mm x mm) Width x Length (inch x feet) | 650x1500 25''x5' | 850x1700 33''x5⅟2'' | 1000x2000 39''x6⅟2' | 1200x2000 47''x6⅟2' | 1500x2000 59''x6⅟2' | 950x2025 37⅟2"x6⅟2' | 1300x2000 51³/16"x6³/5' | 1450x2025 51⅟16"x6⅟2' |

| Power @50hz (kW) Power @50hz (HP) | 2x0.9 2x1.2 | 2x1.96 2x2.8 | 2x1.96 2x2.8 | 2x2.2 2x2.95 | 2x3.2 2x4.3 | 2x1.96 2x2.62 | 2x2.2 2x2.95 | 2x2.2 2x2.95 |

| Power @60hz (kW) Power @60hz (HP) | 2x0.9 2x1.2 | 2x2.3 2x3 | 2x2.3 2x3 | 2x2.3 2x3 | 2x3 2x4 | 2x2.3 2x3 | 2x2.3 2x3 | 2x2.3 2x3 |

| *Capacity (mtph) *Capacity (stph) | 100-180 110-198 | 180-275 198-302 | 220-400 242-440 | 250-500 275-550 | 300-600 330-660 | 220-400 242-440 | 300-550 330-605 | 400-650 440-715 |

| Maximum Feed Size (mm) Maximum Feed Size (inch) | 200 8 | 260 10 | 300 12 | 330 13 | 460 18 | 300 12 | 400 16 | 460 18 |

*At specified inclination and for material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only and depend not only on feeder size but also on feeder inclination, feed gradation, etc.

What is Vibrating Feeder?

Vibrating feeders are used for the constant feeding of crushers at the secondary and tertiary stages.

Types of Vibrating Feeder

How Does Vibrating Feeder Work?

Advantages of Using Vibrating Feeder

Vibrating Feeder Processes Applications

Vibrating feeders mounted onto springs mounts or suspended form, move the material by the vibration generated by 2 vibrating motors. Widely the motors are mounted under the pan of vibrating feeder, but they can also be mounted on top or on both sides of the pan.

In addition to its different intended uses, it primarily regulates the capacity fluctuations that may occur at the primary stage by ensuring regular feeding of crushers at the secondary and tertiary stages.

Vibrating feeders are secondary and tertiary stage equipment and are available in different widths and lengths for different capacities to be used in a wide range of applications such as mining, aggregate or recycling. They typically provide regular and continuous feeding of crushers through a hopper. They are widely used in tunnels under open stockpiles with regular feeding to conveyor belts inside the tunnel.