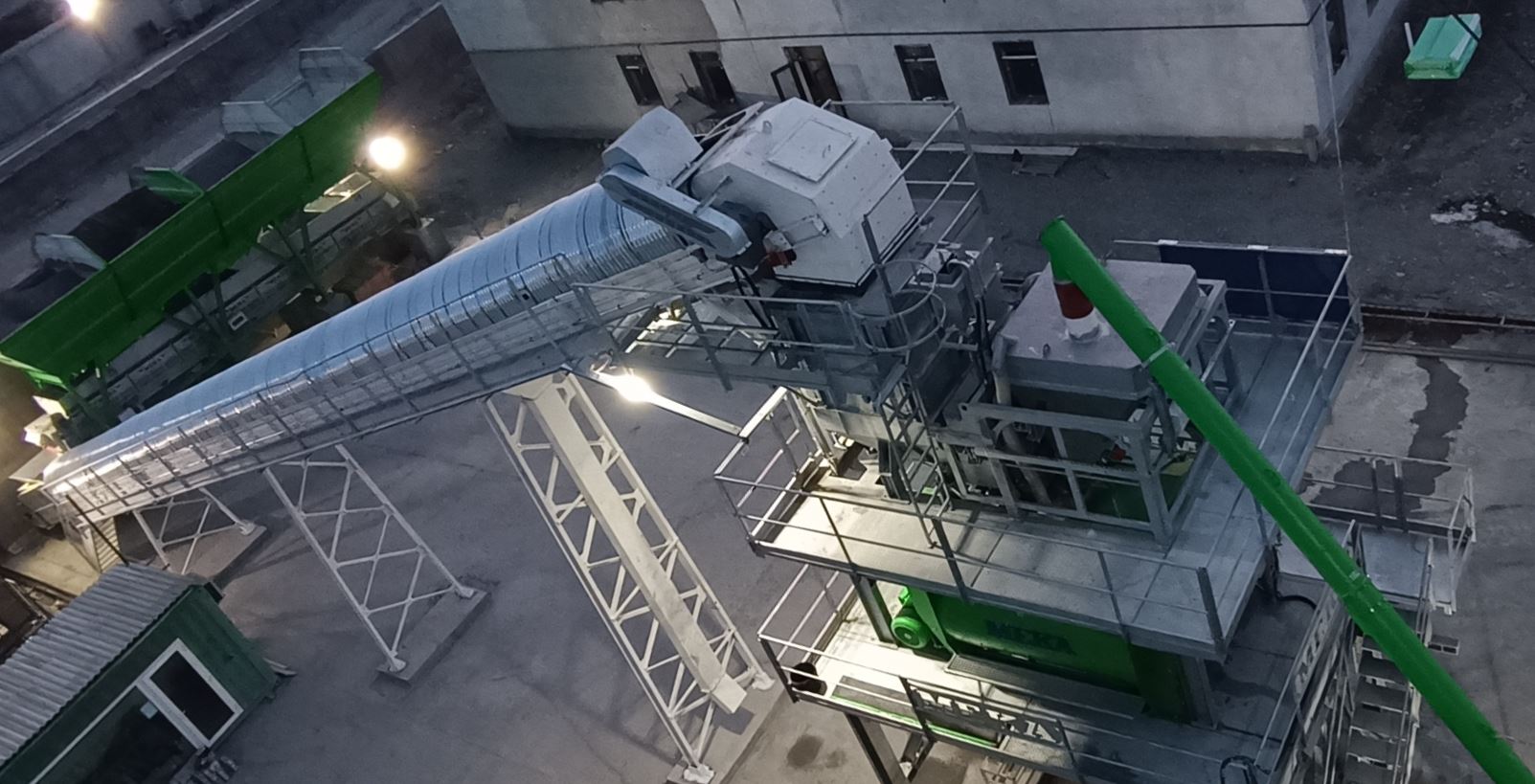

MEKA Compact Sand Plant Has Been Installed in Poland

MEKA compact sand plants continue to receive great recognition from all over the world. Recently, it has been installed in Poland.

Each major component of MEKA Compact Plants is selected to meet the following criteria: Predictable & Reliable Performance over the plant’s lifetime. MEKA has an extensive knowledge base over the performance of its compact plants and we were able to present final product scenarios over a wide range of product feed distributions. Optional spray-bars were added to correct few fractions which proved to be out of ASTM C33 Specifications.

Predicting performance on commissioning day when all the equipment is ready, and every parameter is under control is usually the easier side. Keeping the same performance several months or even years later is another challenge. Natural rubber liners of hydro cyclone and pump are among the longest wearing parts available in the industry. Carefully studying the merits of each case, we make slight changes to our plants to provide maximum wear life. Particle shape, particle size, mineral composition of the feed are an all-important part of our design process. There are different wear protectors including AR Steel, UHMWPE, Polyurethane, Natural Rubber depending on the wear area in a MEKA compact plant. All these different wear parts options allow MEKA to provide reliable performance over a longer time for each application.