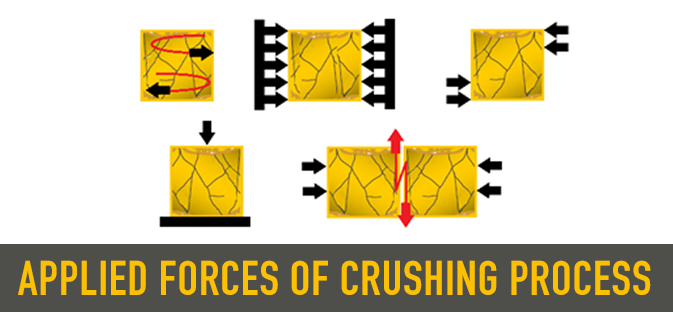

Applied Forces Of Crushing Process

The process of size reduction is defined by below conversion formula:

The ore whose size will be reduced + Energy = Reduced-size ore + Sound + Heat

At the process of size reduction;

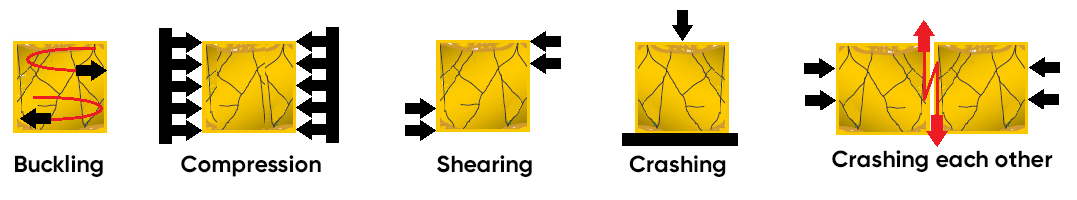

- Buckling

- Compressing or smashing

- Shearing

- Impact

- Forces of repulsion are applied.

Compressing, impact and crashing forces are commonly applied to the There aren’t any which are buckling and shearing forces to applied but these forces can be formed at the event

The distance between hammers and rame screens are quite narrow in the ploughing force applied . The ore is and taken through ploughing force which is formed by effects of crashing and shear forces.

Working with shear force are used when the ores are fragile, contain low silica, and a larger size product is intended as a result of Shear force is usually applied together with crashing and compression forces.

Working with compression force are used to obtain a hard, abrasive, hard to break, sticky ore-free, large-sized product. In these the ore is compressed between one or both moving surfaces. Jaw crashers are the most common size reduction machines for these types of ores. However are also used, where friction force is applied by the horizontal movement of the jaw as well as the compression force. These types of are not suitable for abrasive ores.

Closed circuits are prepared under the control of the upper dimension of the fragile and uncorrosive ore. Most of the time, the first stage breaking is done in open circuit. After the first stage , operating in closed circuit of pre-grinderprovides convenience for management of the grinding also it considerably decrease the cost of size reduction.

The correct selection of circuits is of particular importance as it directly affects subsequent ore preparation, especially grinding. To improve the efficiency of in several stages, use pre-screens to prevent unnecessary reduction of the proper size of ore without entering the . Also this process increases capacity of the r circuits. The amount of ore to be broken, its properties, the intended use of the broken product are the determining factors in the selection of and circuits.