Jaw Crushers

Jaw crushers are primary crushers used to break medium to very hard, dry or low-moisture ores. They are more preferable when durability is more important than capacity. Their reduction ratio ranges from 4:1 to 8:1.

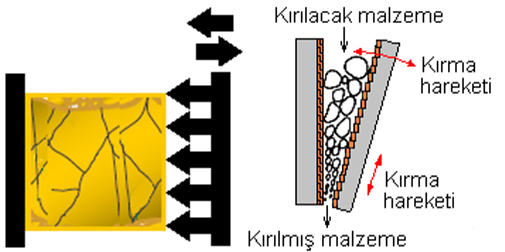

Jaw crushers consist of one fixed and one swing jaw. The working principle of jaw crushers is based on the reciprocating movement of the swing jaw that compresses and crushes the ore between itself and the fixed jaw

Compression is repeated several times until the rock leaves the crusher’s discharge end.

Jaw crushers with a small gape are used to crush smaller ores.

The gape and movement of jaw crushers can be adjusted to the ore to be crushed and the desired size of the material. The chunks of ore crushed between the jaws fall below by their own weight. They are compressed between the jaws as they fall further.

Jaws of high-oscillation crushers are opened and closed a higher number of times and chunks of ore travel a shorter distance when falling below by their own weight in between the jaws. Hence, the ore is compressed a higher number of times along the jaws and thus is exposed to higher crushing forces, thereby being reduced to smaller sizes. High number of oscillating motions of the jaw increases the amount of fine product. Crushers with a lower oscillating motion yield a product of a larger size.

The amplitude of oscillation of the swing jaw in a jaw crusher is about 4-6 mm at the inlet and 15-25 mm at the outlet. The number of oscillations of the jaw ranges from 180 to 250 oscillations/minute, while this figure reaches 275-400 oscillations/minute when doing fine crushing.

Since large blocks are crushed in jaw crushers, a grid must always be used before the crusher to prevent rocks larger than the inlet of the crusher from getting stuck at the inlet, thereby avoiding any potential damage to the crusher. Large chunks that do not pass through the grid should be broken manually or using appropriate machinery. This is crucial in that it helps avoid any interruption to the crushing operations.