-

PRODUCTS

-

Ready Mix Concrete Plants

- READY MIX CONCRETE PLANTS HOME

- MOBILE CONCRETE BATCHING PLANTS

- COMPACT CONCRETE BATCHING PLANTS

-

STATIONARY CONCRETE BATCHING PLANTS

- STATIONARY CONCRETE BATCHING PLANTS HOME

- K60 STATIONARY CONCRETE BATCHING PLANT

- K90 STATIONARY CONCRETE BATCHING PLANT

- K120 STATIONARY CONCRETE BATCHING PLANT

- K135 STATIONARY CONCRETE BATCHING PLANT

- K145 STATIONARY CONCRETE BATCHING PLANT

- K160 STATIONARY CONCRETE BATCHING PLANT

- K200 STATIONARY CONCRETE BATCHING PLANT

- DRY BATCH CONCRETE BATCHING PLANTS

- PRECAST CONCRETE BATCHING PLANT

- RCC CONCRETE BATCHING PLANTS

- Concrete Mixers

- Concrete Plants Components

-

After Sales Services and Spare Part

-

Concrete Batching Plant Automation System

MEKA Global has been a leading manufacturer of concrete batching plants, equipment, and crushing and screening solutions -

Ready Mix Concrete Plants

- CORPORATE

- NEWS

- CONTACT

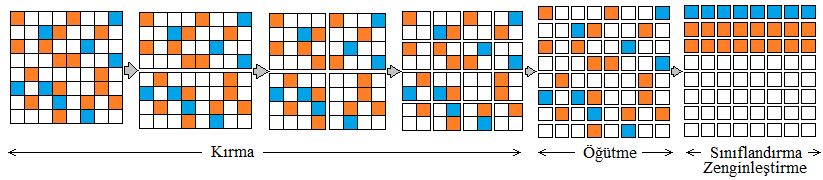

Ruprose Of The Size Reduction

The size reduction process made for three basic purpose:

i. Obtain the size or surface area required for the use of the ore or material:

For this purpose, the rock is broken in the size reduction process. Generally, the necessary filling material in road, construction, asphalt works and raw materials to be used in cement production are prepared.

ii. Separating the different minerals contained in the ore, making one free from the other:

The upper dimension in which the grains are separated as a result of the downsizing process is defined as the liberalization size.

It is the and grinding process for the separation of minerals, which are especially compounded, in order to enrich ores containing one or more precious minerals and unwanted impurities together.

iii. To provide the size or surface area required for the enrichment stage to be applied:

The liberalization size may not always be sufficient for enrichment. It may be necessary to transport a liberalized mineral to the surface with foam following to the flotation, to use the enriched ore in the next stage, or to re-grind the produced for further enrichment.

The re-grinding process of grinded ore to fine-sized ore is named for “regrinding”, “fine grinding “or “re-grinding”.