Again MEKA Concrete Batching Plants Are Preferred for New Investments in Uzbekistan

Our customer, the largest ready-mixed concrete producer in Kokand, Uzbekistan, who made his first investment with a 60 W Meka Stationary Concrete Batching Plant in 2017, preferred Meka again for his new investment in 2023. Our customer stated that he preferred Meka for his new investment due to the high quality, high durability, high production performance and uninterrupted operation of Meka products.

Our customer, who preferred K 140 Meka Stationary Concrete Batching Plant with a capacity of 140 m³ /hour in the new investment, supplies concrete for many construction projects in Kokand city, most of which are undertaken by international companies. He stated that they are the first preferred ready-mix concrete company in the construction projects of international companies thanks to the opportunity to produce high-precision concrete with Meka concrete batching plants.

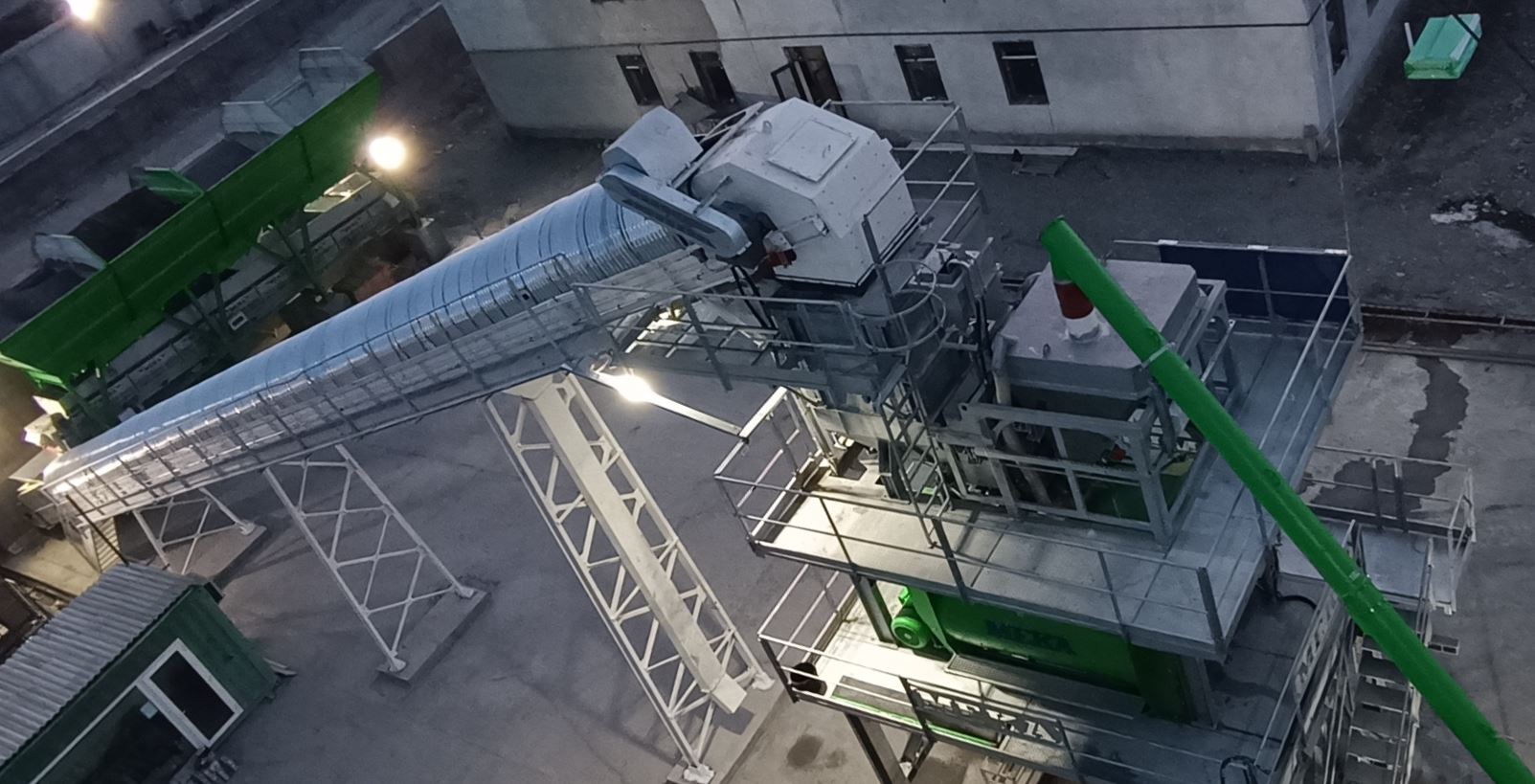

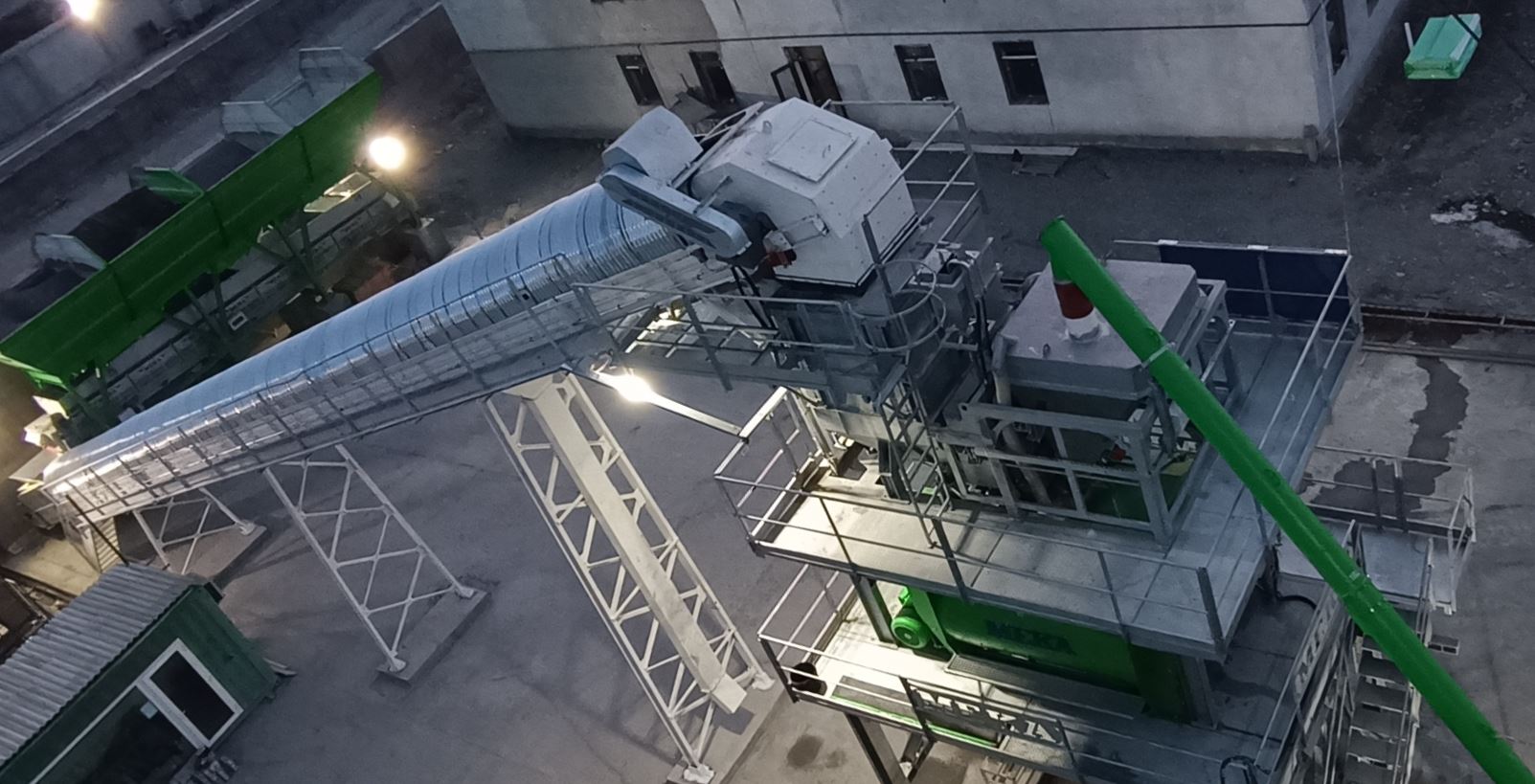

The plant was successfully commissioned by Meka engineers in Kokand city in March 2023 and started concrete production.

The commissioned K 140 stationary concrete batching plant has 4x 25 m³ in-line type aggregate bins. Meka manufactures the aggregate pouring chutes, aggregate dosing hopper and aggregate weighing conveyor under the aggregate bunker in all K 140 concrete batching plants as fully dip galvanized for long life.

In addition, in K 140 concrete batching plants, the main chassis carrier construction, all water-cement-additive weighing groups on the mixer, aggregate accumulation bunker, all main chassis walkways, railings and stairs are completely dip galvanized. This provides a great advantage to users in order to extend the life of these units, which are especially exposed to water, and to increase their corrosion resistance.

K 140 Stationary Concrete batching plant established in Uzbekistan has a 3.33 m³ Meka Twinshaft mixer and MekaSoft Advanced Concrete Production Program designed by Meka software engineers.