-

PRODUCTS

-

Ready Mix Concrete Plants

- READY MIX CONCRETE PLANTS HOME

- MOBILE CONCRETE BATCHING PLANTS

- COMPACT CONCRETE BATCHING PLANTS

-

STATIONARY CONCRETE BATCHING PLANTS

- STATIONARY CONCRETE BATCHING PLANTS HOME

- K60 STATIONARY CONCRETE BATCHING PLANT

- K90 STATIONARY CONCRETE BATCHING PLANT

- K120 STATIONARY CONCRETE BATCHING PLANT

- K135 STATIONARY CONCRETE BATCHING PLANT

- K145 STATIONARY CONCRETE BATCHING PLANT

- K160 STATIONARY CONCRETE BATCHING PLANT

- K200 STATIONARY CONCRETE BATCHING PLANT

- DRY BATCH CONCRETE BATCHING PLANTS

- PRECAST CONCRETE BATCHING PLANT

- RCC CONCRETE BATCHING PLANTS

- Concrete Mixers

- Concrete Plants Components

-

After Sales Services and Spare Part

-

Concrete Batching Plant Automation System

MEKA Global has been a leading manufacturer of concrete batching plants, equipment, and crushing and screening solutions -

Ready Mix Concrete Plants

- CORPORATE

- NEWS

- CONTACT

CANTOMA Increases the Capacity and Quality of Aggregates Production with a Complete MEKA Plant

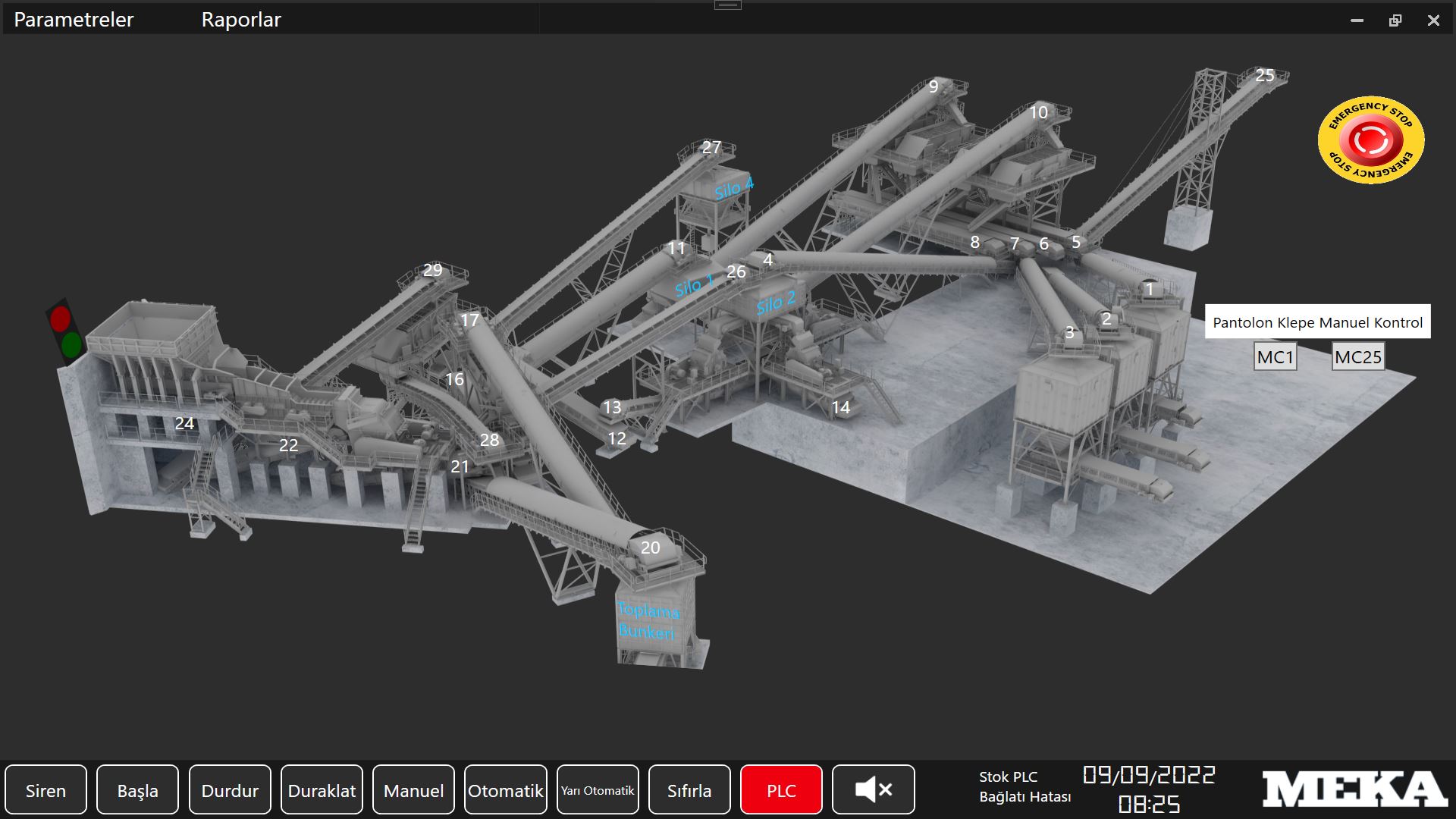

Due to the high demand for aggregates in southeastern Anatolia Türkiye, CANTOMA, wanted to install a new crushing plant in the limestone quarry to increase production capacity and the quality of the end products. MEKA has been chosen as partner for this new strategic project. A complete new crushing plant with 1000 tons/hour capacity was delivered for the production of concrete aggregates and manufactured sand.

Old Site in Need of an Upgrade

Despite numerous re-constructions, the old plant had started to fall behind. The modifications and adjustments over the years had resulted in the production process being slightly off-balance and the daily run-time of the plant was less than expected. Aware of the problems, the CANTOMA site managers started looking into ways of investing in a new plant.

CANTOMA contacted MEKA to explore ways of solving the current problems at the site.Through mutual discussions and on-site inspections, it became clear that whatever the solution would be, it should allow CANTOMA to produce multiple end products sold to ready-mix plants,construction companies, the asphalt industry, and other end-users.

Furthermore, the production volumes of different grain sizes should be adjustable according to current demand, and the production capacity of the most popular end products ought to be increased considerably.

MEKA experts assessed all the production parameters and proposed the installation of a plant with three crushing and screening stages. In the first stage of the project, Primary Impact Crusher is chosen for the maximum reduction of the feed material size; and horizontal shaft impact crushers for upgrading the final product were laid in the second and the third stages. It was suggested to include screening on the horizontal screens in the process line for better material separation, including the small sizes. The conventional three-staged process flow diagram guaranteed the production of high-quality aggregates, optimize the shape of the end products and increase the capacity of the most valuable sizes.

Good Teamwork Brought the Desired Result

All involved in the project have been satisfied with the smooth cooperation and the performance of the new plant.

“The collaboration has been very good from the planning phase and delivery to assembly, start-up, and training. We had some challenges, but we solved them together, we have received good feedback on how the plant is operating, its capacity, and so on’’ Site Manager notes.

Plant Design Criteria

• Material to be processed is soft Limestone

• Feed material size : 0-1300 mm

• The hourly production of required products is 1000 metric tons/hour.

• Products : 0-5mm, 5-10mm, 10-20mm

Equipment Selection

FEED HOPPER with 60 m³ volume,

MAF 1660 APRON FEEDER

MWF 1860/40 WOBBLER FEEDER

MPI 1620 PRIMARY IMPACT CRUSHER

MS 2050/2 INCLINED SCREEN

MSH 1650/2 HEAVY DUTY INCLINED SCREEN

MSI 1115H SECONDARY IMPACT CRUSHER

50 m³ SURGE BIN WITH 2 BELT FEEDERS

MHS 2460/3 HORIZONTAL SCREENS (4 pieces)

30 m³ SURGE BIN WITH BELT FEEDER

MTI 1115 TERTIARY IMPACT CRUSHER (3 pieces)

50 m³ SURGE BIN WITH 3 BELT FEEDERS

120 m³ PRODUCT SILOS (3 pieces)

TRUCK LOADING FEEDERS WITH BELT SCALES

BELT CONVEYORS

PROCESS CONTROL AND AUTOMATION WITH PLC

DUST SUPPRESSION SYSTEM