-

PRODUCTS

-

Ready Mix Concrete Plants

- READY MIX CONCRETE PLANTS HOME

- MOBILE CONCRETE BATCHING PLANTS

- COMPACT CONCRETE BATCHING PLANTS

-

STATIONARY CONCRETE BATCHING PLANTS

- STATIONARY CONCRETE BATCHING PLANTS HOME

- K60 STATIONARY CONCRETE BATCHING PLANT

- K90 STATIONARY CONCRETE BATCHING PLANT

- K120 STATIONARY CONCRETE BATCHING PLANT

- K135 STATIONARY CONCRETE BATCHING PLANT

- K145 STATIONARY CONCRETE BATCHING PLANT

- K160 STATIONARY CONCRETE BATCHING PLANT

- K200 STATIONARY CONCRETE BATCHING PLANT

- DRY BATCH CONCRETE BATCHING PLANTS

- PRECAST CONCRETE BATCHING PLANT

- RCC CONCRETE BATCHING PLANTS

- Concrete Mixers

- Concrete Plants Components

-

After Sales Services and Spare Part

-

Concrete Batching Plant Automation System

MEKA Global has been a leading manufacturer of concrete batching plants, equipment, and crushing and screening solutions -

Ready Mix Concrete Plants

- CORPORATE

- NEWS

- CONTACT

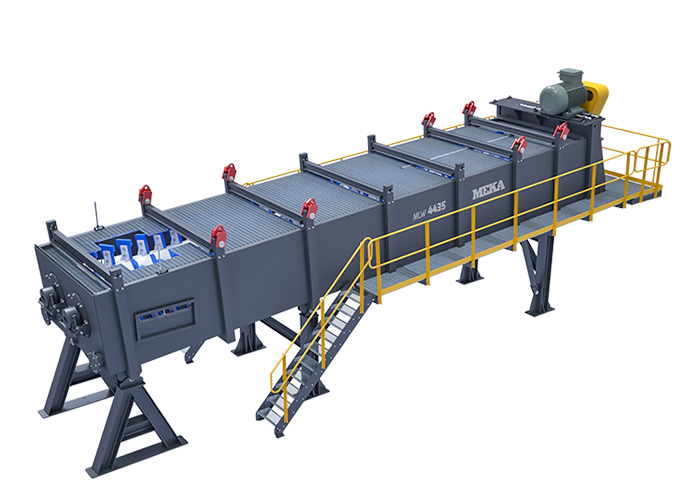

MLW Series

Log Washers

MEKA Log Washers effectively scrub clay, silt, and sticky substances from aggregates, hard ore, recycling materials, and other materials. Its extra-strong body and numerous superior features, designed for harsh conditions, ensure uninterrupted production and maximum cleaning performance.

Is your problem cleaning heavily soiled raw materials?

MEKA Log Washers are right solution.

-

00 Ni-Hard Paddles for Longer Durability

MEKA log washers are available with various options to suit your needs. Paddles are manufactured as standard in Ni-Hard for extra durability. -

01 Robust Body Structure

The body of MEKA log washers, significantly heavier than its competitors, is designed with additional reinforcement for long-term durability and production under the most severe conditions. -

02 Angle-Adjustable Washer Body

The MEKA Log Washer body can be positioned at an angle of 0 to 5 degrees, allowing you to adjust the material's residence time in the wash chamber and the washing efficiency based on the material. -

03 Quality Components That Make a Difference in Every Detai

MEKA Log Washers utilize the highest standards of components, from bearings and motors to belts, down to the smallest detail. This ensures easy maintenance and parts availability worldwide, ensuring uninterrupted profitability.

-

MEKA Log Washer Download Catalogue

MEKA Log Washers are specifically designed to provide highly efficient scrubbing of clay, silt, and other contaminants adhering to the surfaces of aggregates and ores. Their twin-shaft, helical paddle structure transports the material upwards with a powerful scrubbing action during the washing process. Simultaneously, the directed water flow flushes fine-grained contaminants and removes any remaining residue in the final rinse line.The Ni-Hard paddles used in the MEKA Log Washer system offer high wear resistance, while the specialized gearbox provides superior performance against high impact loads. Adjustable body angles between 0 and 5° allow for the optimization of washing time for various applications, ensuring maximum cleaning.Compared to its competitors, the MEKA Log Washer offers low maintenance costs and a long service life with its significantly heavier and more rigid body structure and easily replaceable wear parts.

Applications

Aggregate Production

Ore Processing

Mineral Preparation in Mining and Industrial Operations

Recycling Applications

MLW 3630 |

MLW 4430 |

MLW 4435 |

MLW 4835 |

|

| Screw Diameter (mm) | 945 | 1120 | 1120 | 1225 |

| Tube Length (mm) | 9175 | 9300 | 10820 | 10500 |

| *Capacity (mtph) | 50-125 | 75-175 | 75-175 | 110-365 |

| Material (mm) | 75 | 102 | 102 | 150 |

| Power (kW) | 2x55 | 160 | 160 | 200 |

| Screw (rpm) | 32 | 26 | 26 | 26 |

| **Weight (kg) | 26074 | 32275 | 37150 | 42185 |

| Water (m3/h) | 114 | 171 | 171 | 190 |

Log Washer is a washing equipment consisting of two rotating paddle shafts to provide materail- on materail scrubbing. Log Washers are used to remove tough, plastic clays in a variety of material processing applications.

This process helps to dislodge and remove contaminants like clay, mud, and organic matter from the coarse material.As the coarser materials move through up the log washer to be discharged from, while lighter materials like clay and sand are carried away with the water flow back.

Can be adopted according to feed material specifications. Possibility of increasing of the quality of the washed product. Possibility of rinsing the material prior to discharge.