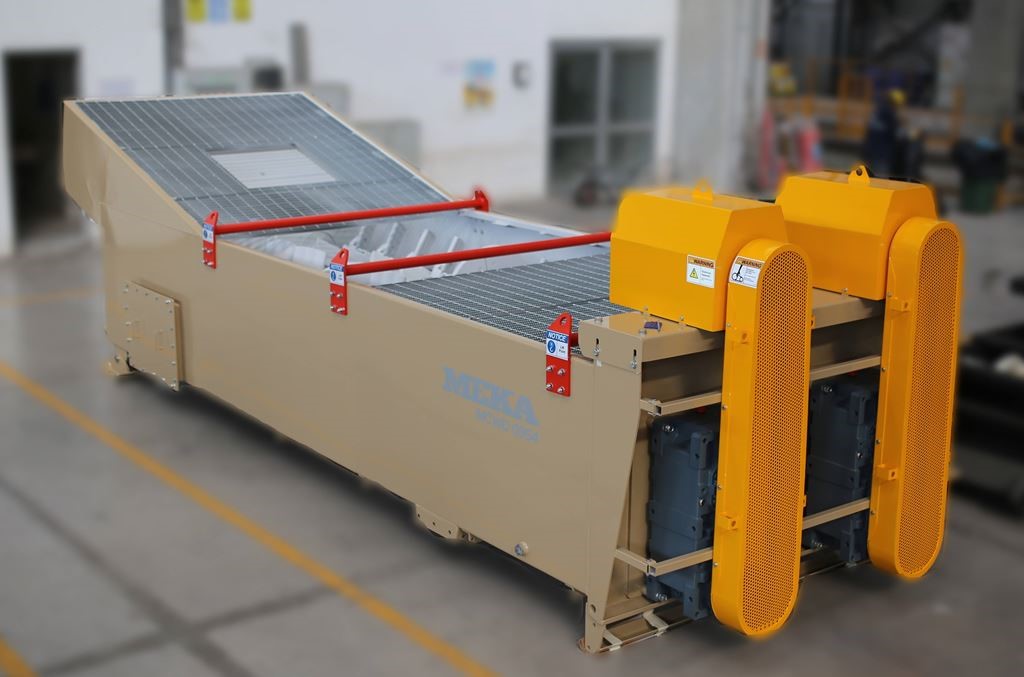

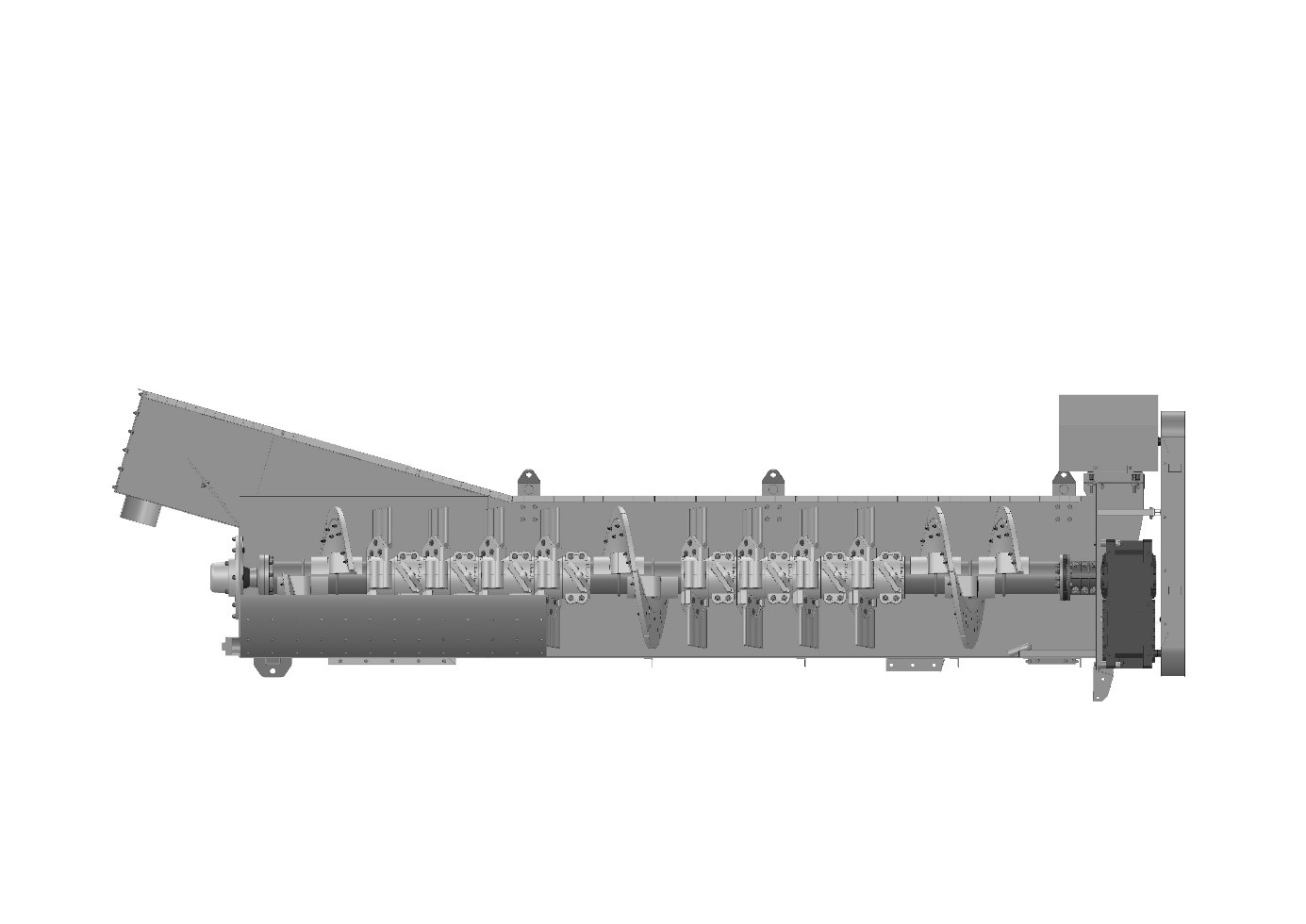

Coarse Material Washer

Coarse material washers are used to remove insoluble or soluble dirty material from a coarse aggregate. This material includes very water soluble slimes, silts, soft clay, and organic particles. They are often used as a final wash following a wet screen and are designed to scrub and clean gravel and crushed stone up to 75mm (3’’) in size. It’s most distinguished feature is stable scrubbing abilitties under harsh conditions.

Both single and double spiral units are available depending on the capacity required.Classifying is accomplished when coarse material containing dirty material that has a specific gravity less than the coarse material is floated upwards and carried over the adjustable weirs at the back of the machine.

Paddles on the coarse washer screw provide light scrubbing and washing to remove soluble clays, and fines associated with crushing. Paddles also provide jigging action to float up sticks, roots, and lightweight coals to be flushed over the feed end of the tub by the rising current.

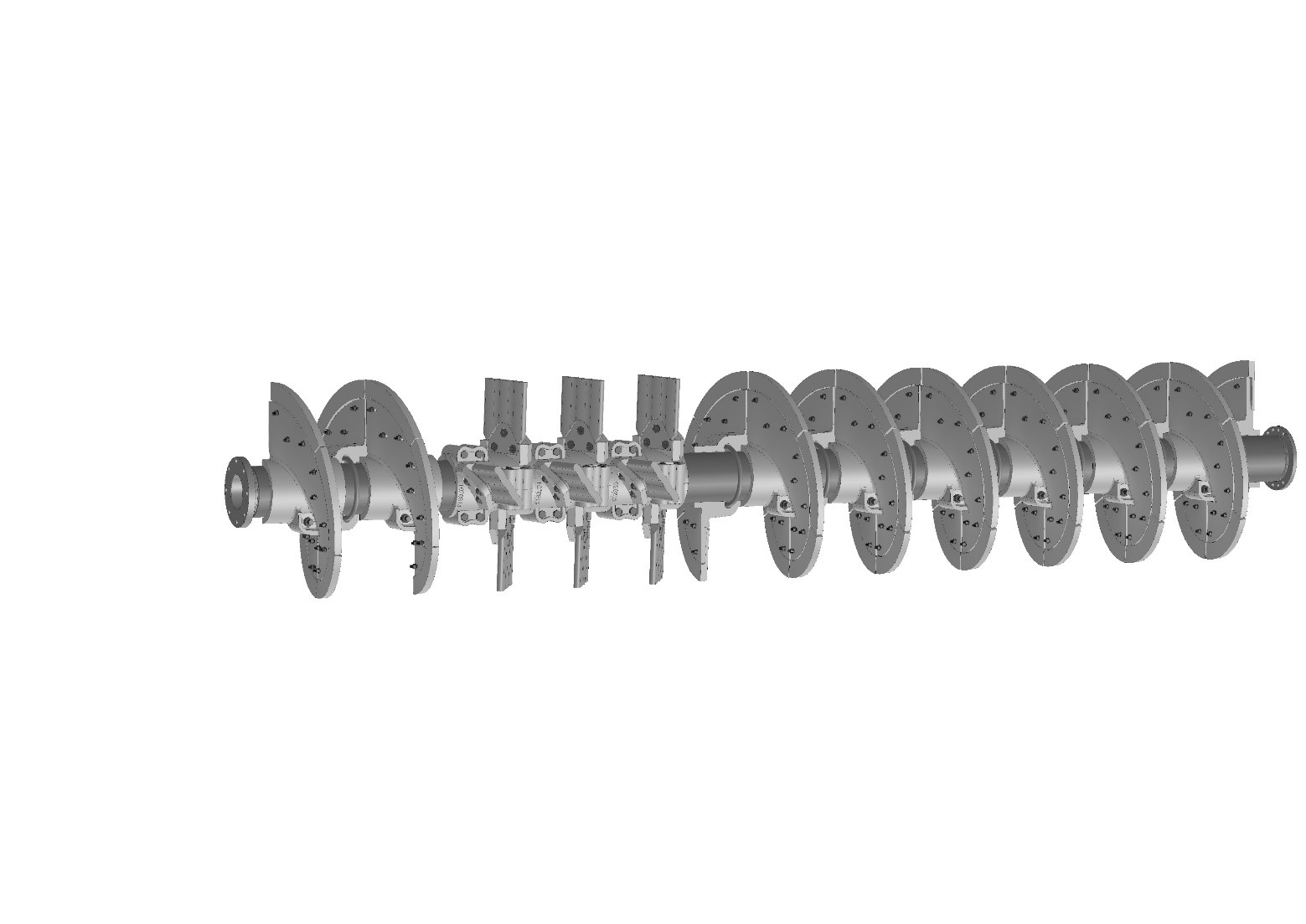

Blade Mills are another configuration of coarse washer. Single full spiral revolution at the feed and discharge end as well as the middle of the shaft equipped with scrubbing paddles. Paddles are placed in between spiral to provide maximum scrubbing on rock and sand. Producers can install reverse handed paddle assemblies to keep material in the scrubbing zone for longer periods of time.

FEATURES/BENEFITS

1. The high efficiency V belt drive assembly reduces power and maintenance requirements resulting in increased life and reduced operating costs.

2. Remove dirty materials

3. Oil lubricated heavy duty gear box

4. Heavy duty shafts

5. Simple replacement parts assemblies

6. Easy access outboard bearing assemblies

7. Interchangeable paddles and spirals allow customization to maximize scrubbing capabilities (36’ diameter)

8. Hardened paddles have corrugated surface for maximum scrubbing

9. Paddles and spiral hubs enclose shaft for wear protection

10. Rising current manifold provides upward current to flush out unwanted particles