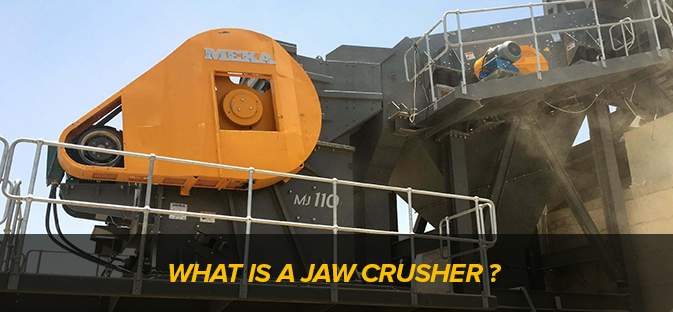

What Is A Jaw Crusher

WHAT IS A CRUSHING PROCESS? / CRUSHING

In order to make use of the rocks or ores obtained through quarrying/explosion in the Mining and Construction sectors, the materials need to be crushed to reduce them to a smaller size. We call this process SIZE REDUCTION or CRUSHING.

The goals of the size reduction are as follows:

1.) Obtaining the size or surface area required for the use of the ore or material

2.) Allowing ease of transportation and storage

3.) Separating the different minerals contained within the ore and to release them from one another

4.) Obtaining the size or surface area required for the enrichment stage.

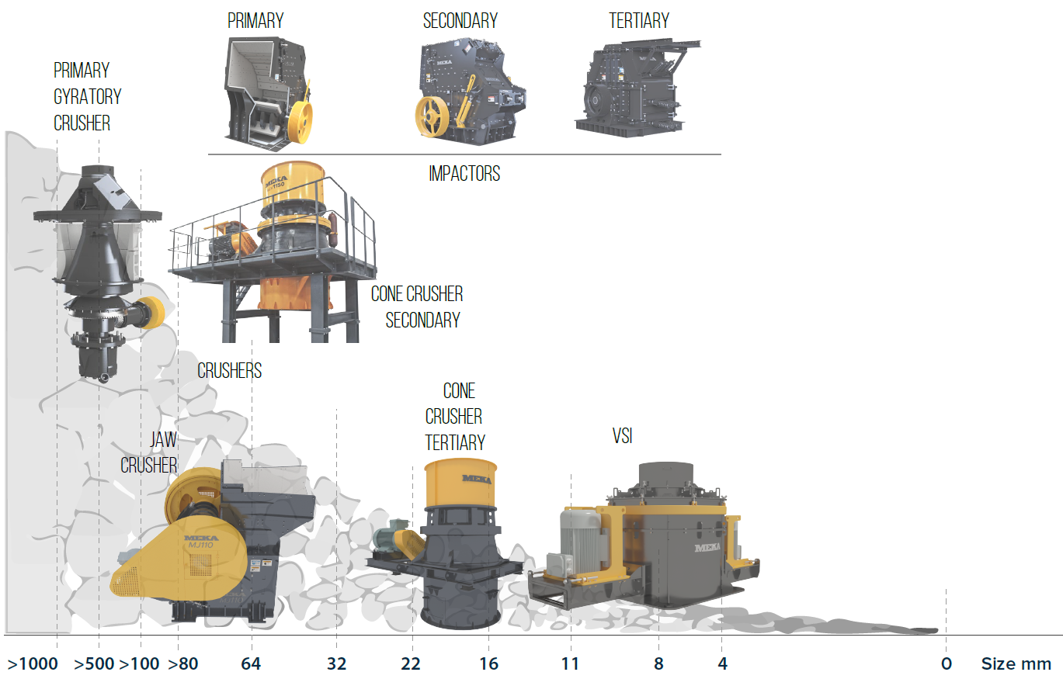

In general, crushing is carried out in three stages, depending on the desired size of the material.

Primary Crushing

This is the first stage of the crushing process. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm.

Secondary Crushing

This is the second stage of crushing. Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm.

Tertiary Crushing

This is the third stage of crushing. The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and 12 mm.

We call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER.

WHAT IS A JAW CRUSHER? / JAW CRUSHER

This is a type of crusher that is widely used in the primary and secondary crushing processes.

It is usually preferred for the crushing of large blocks of hard and abrasive materials.

HOW DO JAW CRUSHERS WORK? / THE WORKING PRINCIPLE OF JAW CRUSHERS

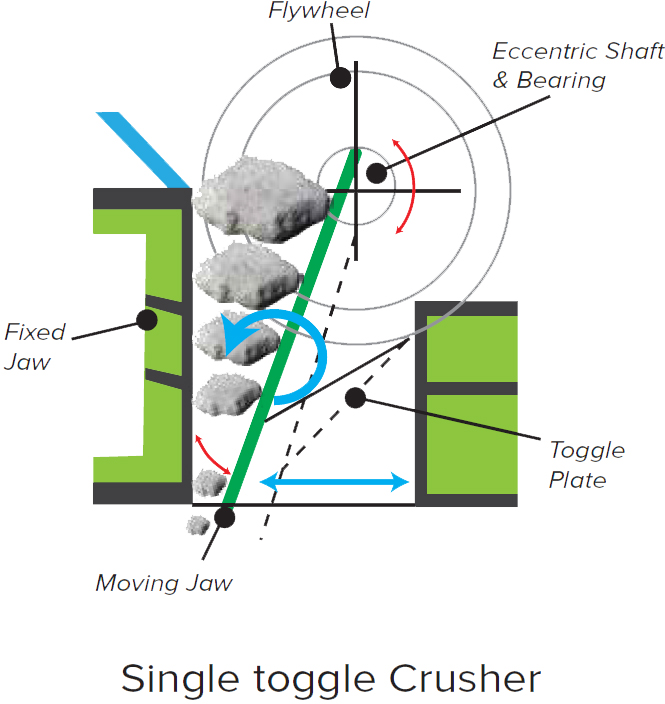

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

The moving jaw moves back and forward against the fixed jaw, and material fed from the top of the machine is compressed between the two, breaking it into smaller pieces. As the moving jaw moves away from the fixed jaw, the crushed material is discharged from the crusher at the bottom, with the size of the ejected material determined by the gap between the jaws.

WHAT ARE THE MAIN COMPONENTS OF JAW CRUSHERS? / PARTS AND MAIN PARAMETERS OF JAW CRUSHERS

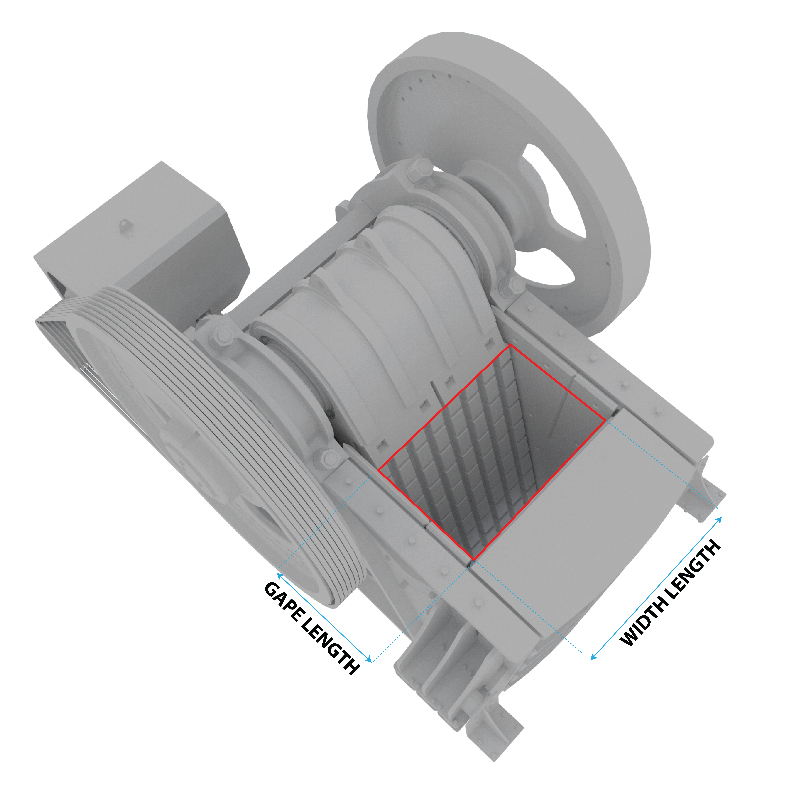

Jaw crushers are generally defined by their opening size.

For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm.

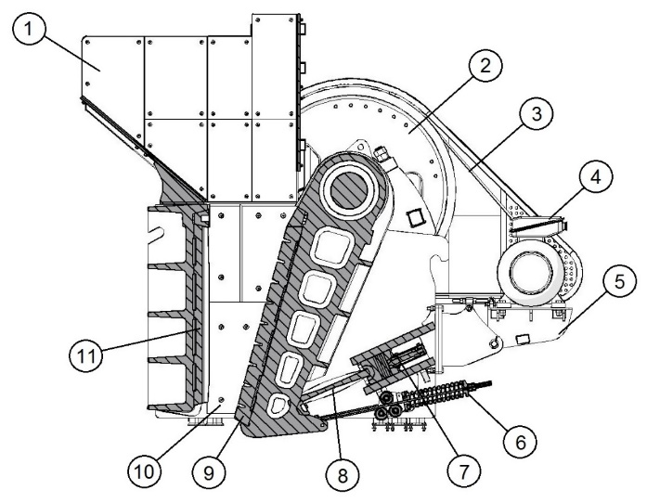

The main parts and main technical parameters of a jaw crusher are presented below.

1. Feed Chute

2. Drive Flywheel

3. V-belts

4. Electric motor

5. Motor Stand

6. Settings and Damping Group

7. Hydraulic Cylinder

8. Toggle Plate

9. Swing Jaw

10. Discharge

11. Fixed Jaw

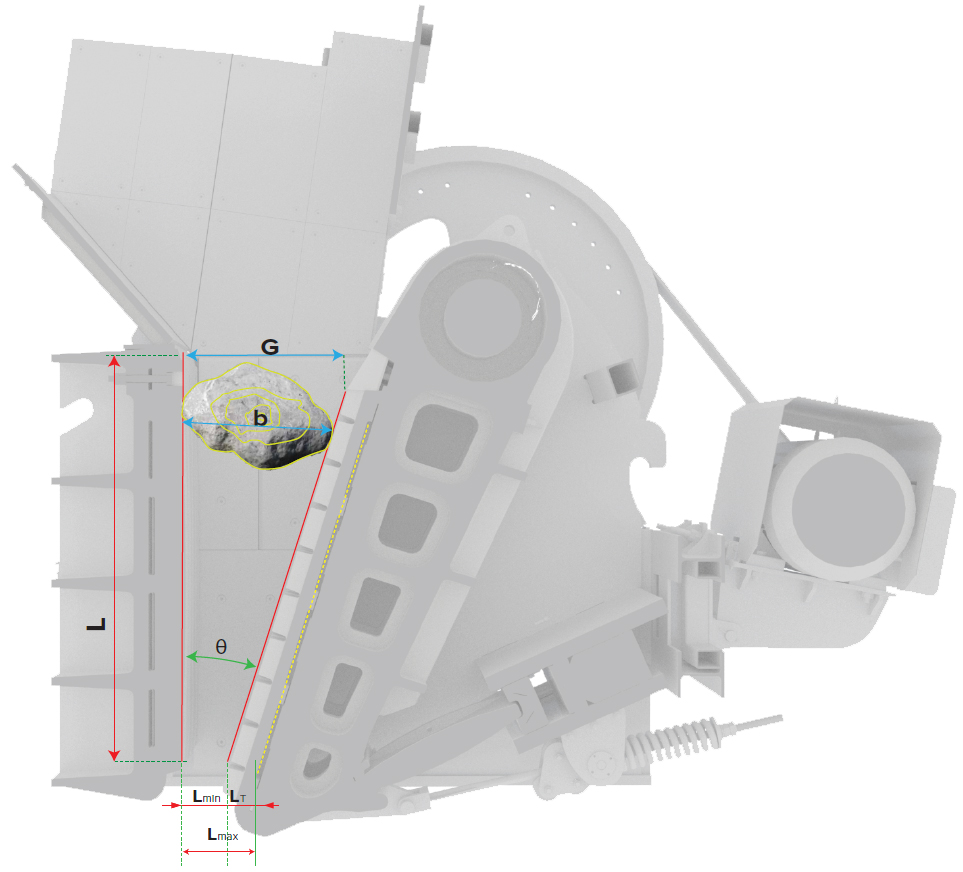

G: Gape width,

b: maximum feed size,

This is generally desired to be between 80% and 90% of the inlet width

L: area length

Around double the gape width

W: area width

Varies between 1.3 and 3 times the gape width.

Lmax (OSS): Far side jaw opening (OPEN SIDE SETTING)

Lmin (CSS): Near-side jaw opening (CLOSED SIDE SETTING)

Stroke (LT)

Minimum and maximum movability of the lower end of the jaw. This is equal to the OSS minus the CSS.

R: Size reduction ratio

The ratio of the gape width to the near side jaw opening.

This ratio may vary from 1/3 to 1/9, but is generally 1/3 for and 1/4 for secondary

θ: Nip angle

One of the most important parameters is the angle between the two jaws, which is referred to as the nip angle. The nip angle is the angle at which the material, that passes through the inlet to be between the jaws can be gripped by the jaws without slipping. This angle depends on the size, hardness and frangibility of the material. It cannot be selected as too large or too small. The nip angle in primary is lower than in secondary

Generally, this value is between 18 and 24 degrees in primary, and between 22 and 28 degrees in The nip angle can be 33 degrees maximum.

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER? / JAW CRUSHER TYPES

There are two main groups of jaw crushers, categorized according to their jaw movement mechanism.

- Single-toggle jaw crushers

- Double-toggle jaw crushers

In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached. The pitman is supported by a toggle plate at the bottom of the moveable jaw. Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in an elliptical orbit. This mechanism makes a movement aka four bar linkage movement. Through this movement, the movable jaw applies both pressure and friction forces to the material to be crushed.

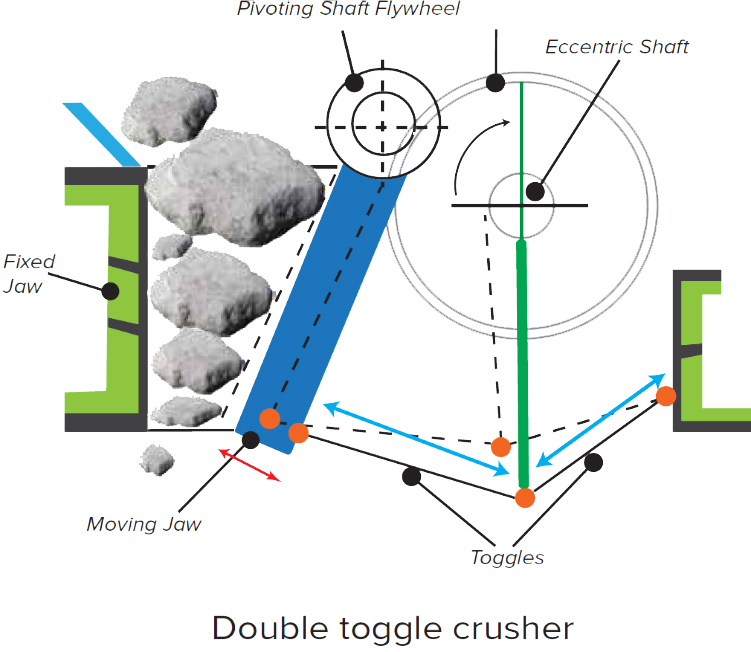

In double-toggle jaw crushers, the pitman is mounted on fixed non-eccentric shaft that situated at the top of the crusher. There are two toggle plates, one on the left and one on the right, are linked to the pitman that is hinged to the driven camshaft. The toggle plate on the left is linked to the jaw-supporting block, while the one on the right is linked to the main body.

The mechanism of double-toggle jaw crushers allows applying only pressure on the material.

A comparison of jaw crushers with the same capacity reveals that double-toggle jaw crushers are more expensive than ordinary jaw crushers. For this reason, mostly single-toggle jaw crushers are used in the aggregate sector, while double-toggle jaw crushers are used mostly for crushing very hard and highly abrasive materials.

The lifecycle of double-toggle jaw crushers is longer since they do not apply friction force.

References:

Mechanical Eng. Msc Suphi Yavuz, Başak Yavuz Makine, Technical Notes

Mining Eng. Msc Necati Yıldız, Ore Dressing and Enrichment Book